Microbial flocculating agent and preparation method thereof

A microbial flocculant and uniform technology, applied in the field of water treatment, can solve the problems of high culture cost, difficulty in strain screening, and insufficient applicability, and achieve the goal of wide application fields, improved sweeping ability, increased cross-linking degree and complexity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

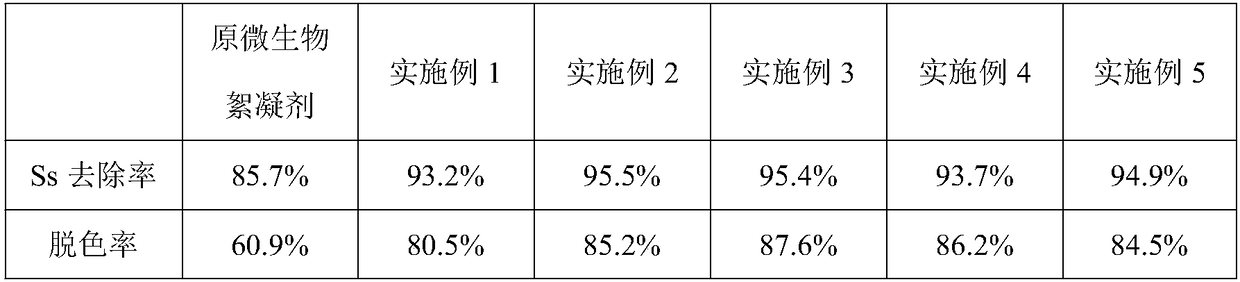

Examples

Embodiment 1

[0030] A microbial flocculant, grafting acrylamide and N,N'-methylenebisacrylamide into the microbial flocculant, the mass ratio of microbial flocculant, acrylamide, N,N'-methylenebisacrylamide It is 1:0.5:0.5.

[0031] A preparation method of microbial flocculant, the method steps are as follows:

[0032] S1: Add the microbial flocculant to deionized water and stir, and stir to 80°C while heating, and stir for 20 minutes until the biological flocculant emulsion becomes transparent and uniform;

[0033] S2: Introduce nitrogen into the reaction vessel to remove oxygen, and under the condition of continuous nitrogen protection, add acrylamide and N,N'-methylenebisacrylamide in proportion, keep stirring for 20 minutes to a uniform state, and then add initiator and urea , keep stirring, and react for 0.5h;

[0034] S3: After the reaction, cool the product to room temperature, adjust the pH to 7, add absolute ethanol to wash 3 times under stirring conditions, rinse 3 times with d...

Embodiment 2

[0040] A microbial flocculant, grafting acrylamide and N,N'-methylenebisacrylamide into the microbial flocculant, the mass ratio of microbial flocculant, acrylamide, N,N'-methylenebisacrylamide It is 1:2:2.

[0041] A preparation method of microbial flocculant, the method steps are as follows:

[0042] S1: Add the microbial flocculant into deionized water and stir, and stir to 95°C while heating, and stir for 30 minutes until the biological flocculant emulsion becomes transparent and uniform;

[0043] S2: Introduce nitrogen into the reaction vessel to exclude oxygen, under the condition of continuous nitrogen protection, add acrylamide and N,N'-methylenebisacrylamide in proportion, keep stirring for 30min to a homogeneous state, then add initiator and urea , keep stirring, react for 2h;

[0044] S3: After the reaction, cool the product to room temperature, adjust the pH to 8, add absolute ethanol to wash twice, rinse twice with deionized water, and then extract the crude pro...

Embodiment 3

[0050] A microbial flocculant, grafting acrylamide and N,N'-methylenebisacrylamide into the microbial flocculant, the mass ratio of microbial flocculant, acrylamide, N,N'-methylenebisacrylamide It is 1:1:1.

[0051] A preparation method of microbial flocculant, the method steps are as follows:

[0052] S1: Add the microbial flocculant to deionized water and stir, and stir to 90°C while heating, and stir for 25 minutes until the biological flocculant emulsion becomes transparent and uniform;

[0053] S2: Introduce nitrogen into the reaction vessel to exclude oxygen, and under the condition of continuous nitrogen protection, add acrylamide and N,N'-methylenebisacrylamide in proportion, keep stirring for 25 minutes to a uniform state, and then add initiator and urea , keep stirring, react for 1h;

[0054] S3: After the reaction, cool the product to room temperature, adjust the pH to 7.5, add absolute ethanol to wash twice, rinse with deionized water three times under stirring c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com