Method for preparing sapphire-level high-purity alumina from aluminum profile anodic oxidation waste liquids

A high-purity alumina and anodizing technology, applied in the preparation of alumina/hydroxide, etc., can solve the problems of difficult to form mass production scale, difficult to control process parameters, harsh required conditions, etc., to achieve good social effects, Good economic benefits and simple raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

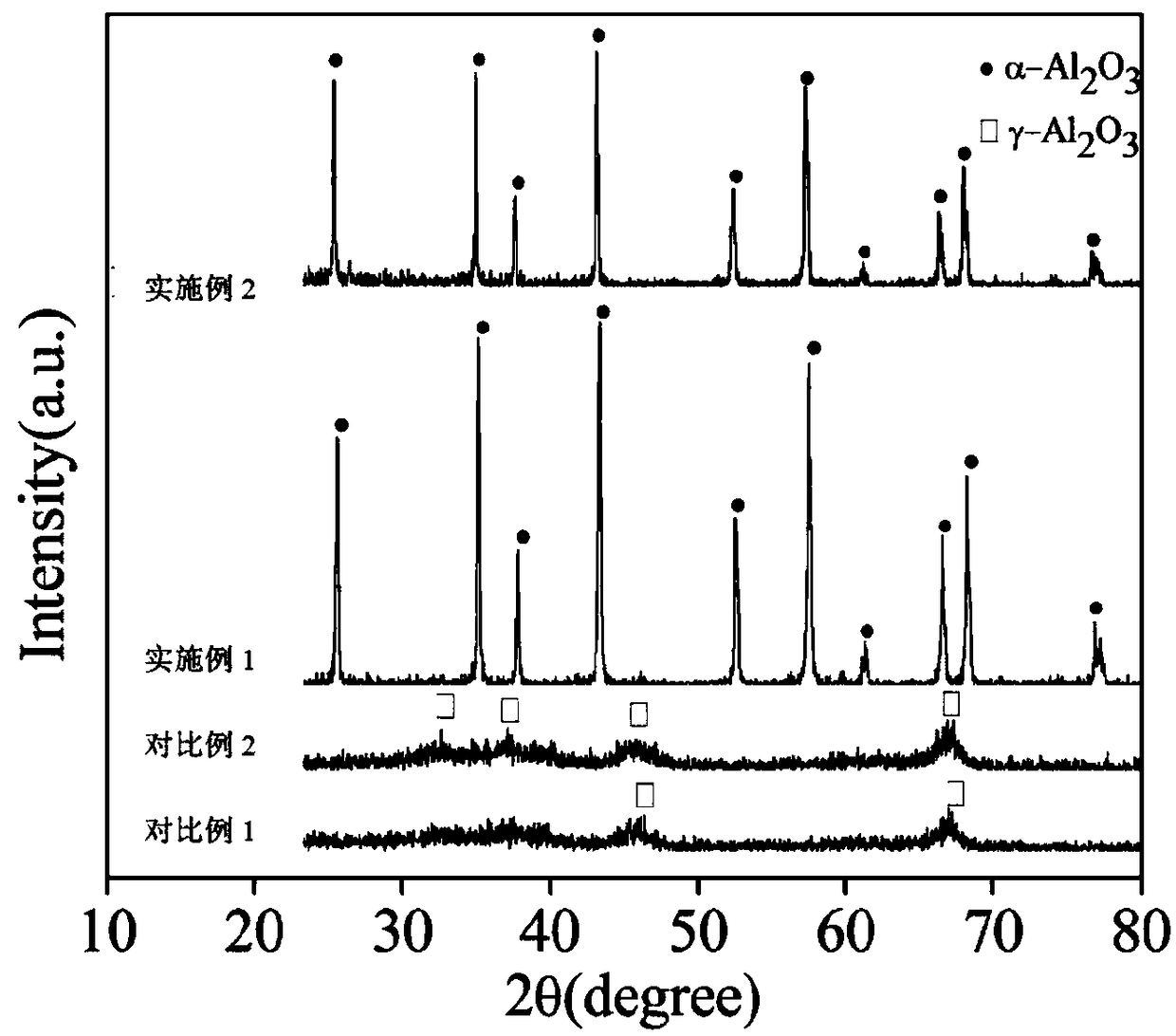

Embodiment 1

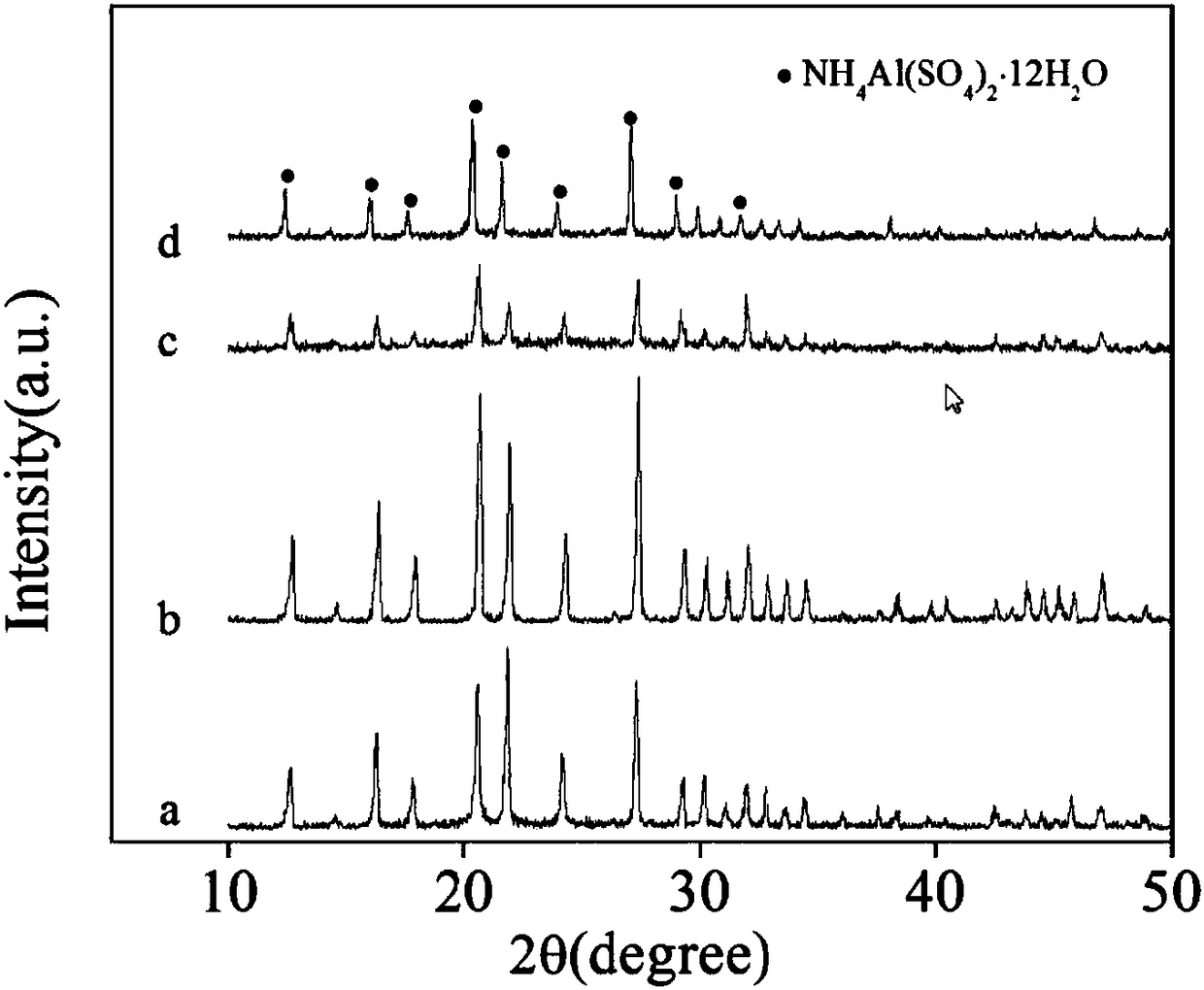

[0035] This embodiment provides a method for preparing sapphire-grade high-purity alumina using aluminum anodic oxidation waste liquid, and the specific steps are as follows:

[0036] 1) Pretreatment of aluminum anodic oxidation waste liquid

[0037] Take the aluminum anodic oxidation waste liquid in the production process of an aluminum profile. After testing, it can be known that the main component of the waste liquid is Al 2 (SO 4 ) 2 and H 2 SO 4 , the content of aluminum is 0.58wt%, and the impurity content is Ca 2+ : 3.4ppm, Fe 2+ : 6.4ppm, Mg 2+ : 1.0ppm, Na + : 2.8ppm, Si 4+ :1.4ppm;

[0038] Taking 1L of waste liquid as an example, add 10g of activated carbon to the waste liquid and stir for 30min, remove the adsorbed impurity Fe by suction filtration 2+ Then add 0.6gD001 ion resin, stir for 40min, remove the complex formed by ion exchange resin and Mg ion by suction filtration; add 60ml hydrofluoric acid (concentration is 400g / L), react for 50min, filter to...

Embodiment 2

[0048] This embodiment provides a method for preparing sapphire-grade high-purity alumina using aluminum anodic oxidation waste liquid, and the specific steps are as follows:

[0049] 1) Pretreatment of aluminum anodic oxidation waste liquid

[0050] Take the aluminum anodic oxidation waste liquid in the production process of an aluminum profile. After testing, it can be known that the main component of the waste liquid is Al 2 (SO 4 ) 2 and H 2 SO 4 , the content of aluminum is 0.58%, and the impurity content is Ca 2+ : 3.4ppm, Fe 2+ : 6.4ppm, Mg 2+ : 1.0ppm, Na + : 2.8ppm, Si 4+ :1.4ppm;

[0051] Taking 1L of waste liquid as an example, add 12g of activated carbon to the waste liquid and stir for 30min, remove the adsorbed impurity Fe by suction filtration 2+ Then add 0.8gD001 ion resin, stir for 50min, remove the complex formed by ion exchange resin and Mg ion by suction filtration; add 80ml hydrofluoric acid (concentration is 400g / L), react for 50min, filter to r...

Embodiment 3

[0061] This embodiment provides a method for preparing sapphire-grade high-purity alumina using aluminum anodic oxidation waste liquid, and the specific steps are as follows:

[0062] 1) Pretreatment of aluminum anodic oxidation waste liquid

[0063] Take the aluminum anodic oxidation waste liquid in the production process of an aluminum profile. After testing, it can be known that the main component of the waste liquid is Al 2 (SO 4 ) 2 and H 2 SO 4 , the content of aluminum is 0.58%, and the impurity content is Ca 2+ : 3.4ppm, Fe 2+ : 6.4ppm, Mg 2+ : 1.0ppm, Na + : 2.8ppm, Si 4+ :1.4ppm;

[0064] Taking 1L of waste liquid as an example, add 5g of activated carbon to the waste liquid and stir for 10min, remove the adsorbed impurity Fe by suction filtration 2+ Then add 0.4gD001 ion resin, stir for 50min, remove the complex compound formed by ion exchange resin and Mg ion by suction filtration; add 100ml hydrofluoric acid (concentration is 400g / L), react for 60min, fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com