Automatic punching machine for fingerprint module machining

A technology of fingerprint modules and punching machines, which is applied in metal processing, metal processing equipment, and machine tools designed for grinding the rotating surface of workpieces, etc. wear and improve productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

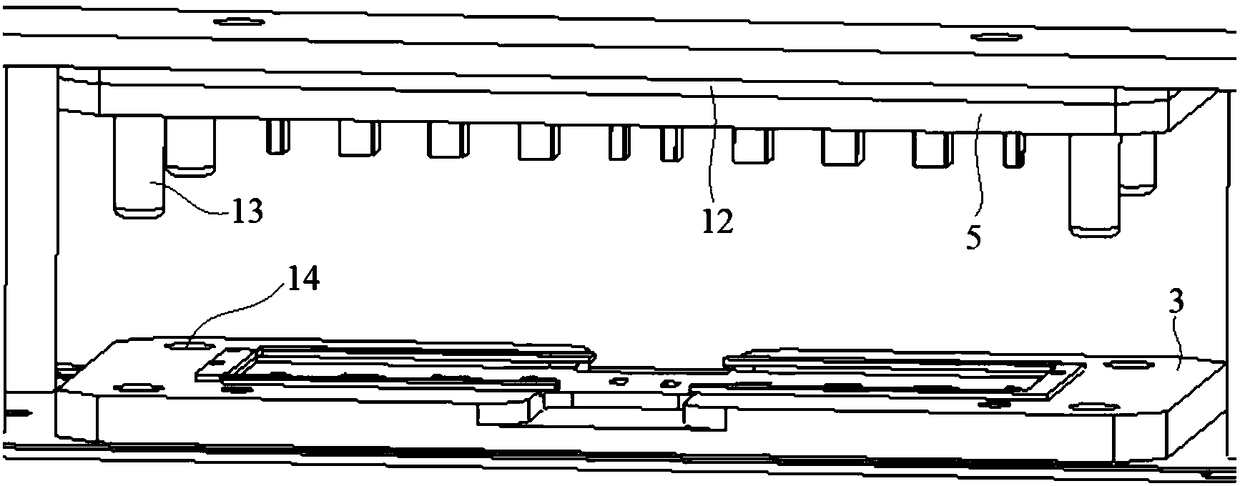

[0038] Embodiment 1: An automatic punching machine for fingerprint module processing, including a base 1, a base plate 2, a carrier plate 3, a pressing plate 5 with a stamping head 4, a movable plate 6 and a fixed plate 7, and the base plate 2 is installed on the base 1 upper surface, the carrier plate 3 is arranged on the upper surface of the base plate 2, the base plate 2 and the fixed plate 7 are fixedly connected by at least two guide posts 8, the upper surface of the fixed plate 7 has a cylinder 9, the cylinder The piston rod of 9 passes through the fixed plate 7 and is fixedly connected with the movable plate 6 located below the fixed plate 7, the pressing plate 5 is installed on the lower surface of the movable plate 6, and the punching head 4 is evenly arranged on the lower surface of the pressing plate 5;

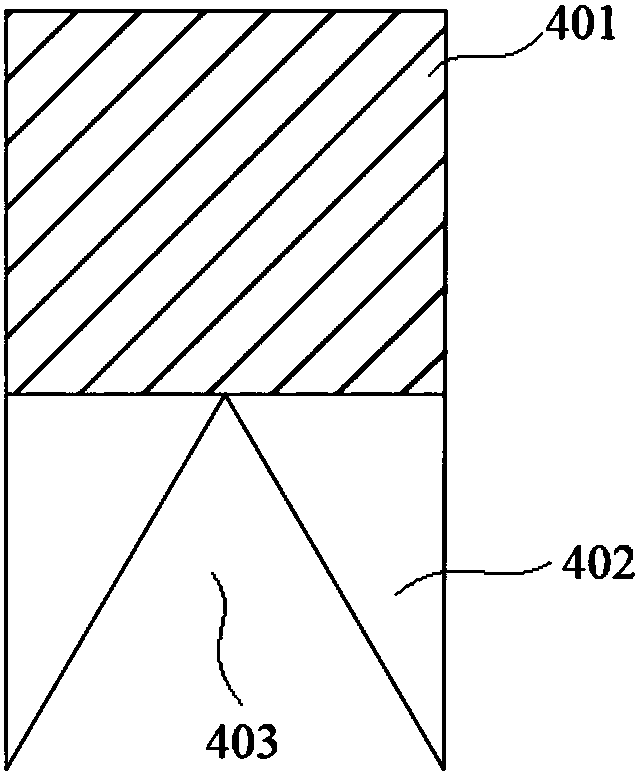

[0039] The punch 4 is composed of a body part 401 and a punch part 402, the upper surface of the body part 401 is connected to the lower surface of the pressing pla...

Embodiment 2

[0050] Embodiment 2: An automatic punching machine for fingerprint module processing, including a base 1, a base plate 2, a carrier plate 3, a pressing plate 5 with a stamping head 4, a movable plate 6 and a fixed plate 7, and the base plate 2 is installed on the base 1 upper surface, the carrier plate 3 is arranged on the upper surface of the base plate 2, the base plate 2 and the fixed plate 7 are fixedly connected by at least two guide posts 8, the upper surface of the fixed plate 7 has a cylinder 9, the cylinder The piston rod of 9 passes through the fixed plate 7 and is fixedly connected with the movable plate 6 located below the fixed plate 7, the pressing plate 5 is installed on the lower surface of the movable plate 6, and the punching head 4 is evenly arranged on the lower surface of the pressing plate 5;

[0051] The punch 4 is composed of a body part 401 and a punch part 402, the upper surface of the body part 401 is connected to the lower surface of the pressing pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com