Full-automatic movable drying line

A mobile, fully automatic technology, used in dry solid materials, dry cargo handling, local stirring dryers, etc., can solve the problems of burning heating and its control module, affecting production planning, tip discharge, etc., to avoid vacuum tip discharge , Shortened baking time, good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the present invention more comprehensible, preferred embodiments are described below in detail with accompanying drawings.

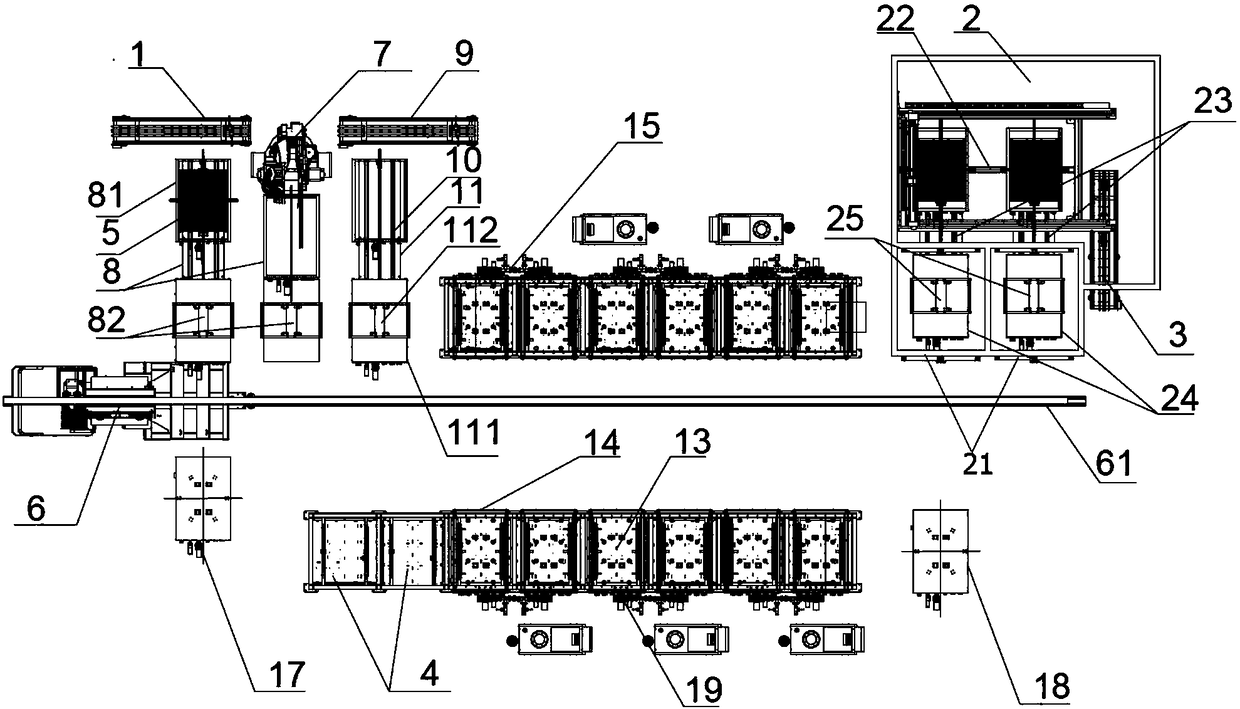

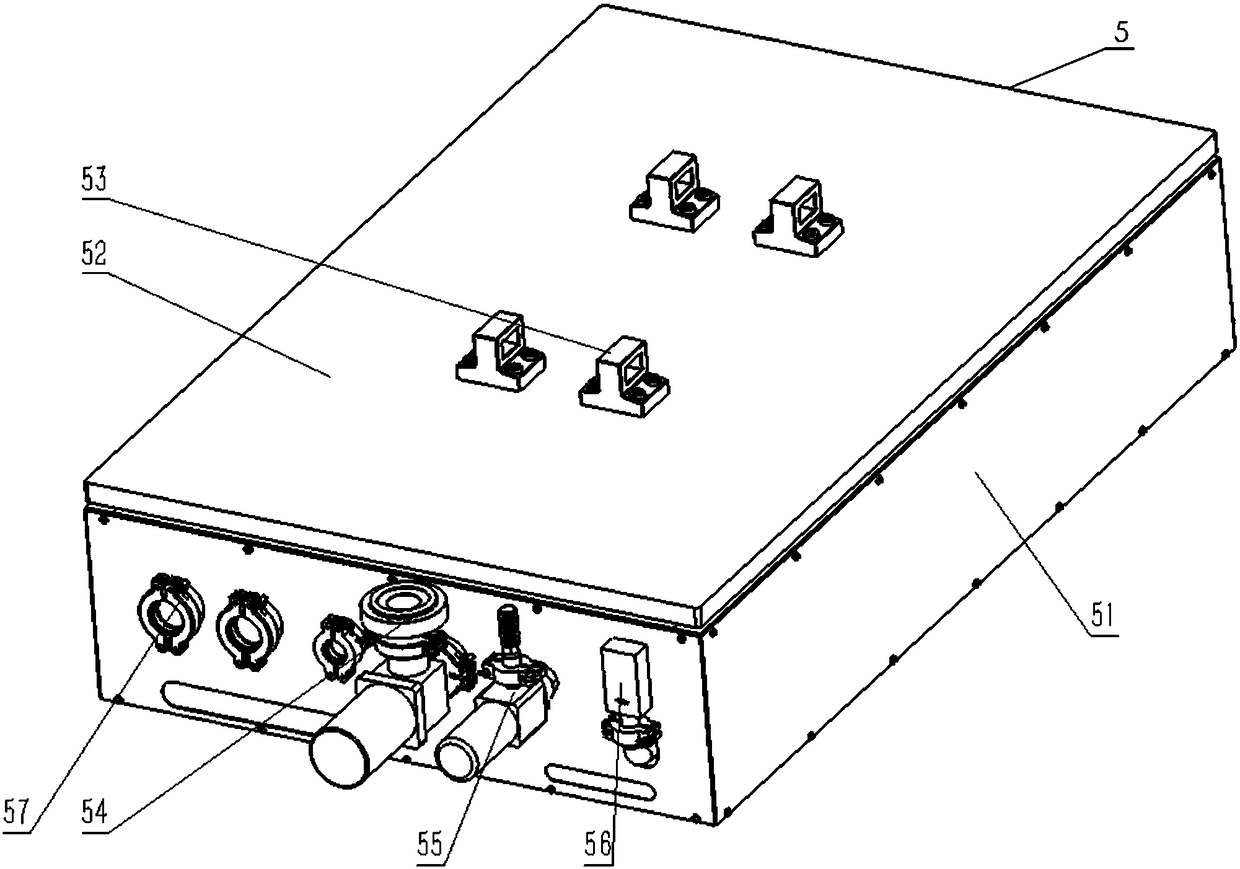

[0031] Combine Figure 1-4 , Fully automatic mobile drying line, with battery feeding input line 1, battery feeding system, three-dimensional shelf baking system, battery unloading system located in drying room 2, and one end connected to drying room 2. The battery unloading output line 3 and the three-dimensional shelf-type buffering position 4 also include a mobile drying box 5 and a stacker 6 and an upper computer control system that realize the transfer of the mobile drying box 5 between various systems; each system is Located beside the stacker lane 61, the stacker 6 is reserved with a network port, which is connected with the upper computer through the network port for cyclic transportation scheduling;

[0032] The end of the battery feeding input line 1 is provided with a code scanner, an in-position sensor and a stopping mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com