Electromagnetic shielding silicon rubber/graphene/carbon nanotube nano composite material and preparation method thereof

A technology of nanocomposite materials and carbon nanotubes, applied in the direction of magnetic/electric field shielding, electrical components, etc., can solve the problems of difficulty in forming a uniform and continuous conductive network, low conductivity of the conductive network, etc., and avoid the use of dispersing additives, structure The effect of uniformity and improvement of electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

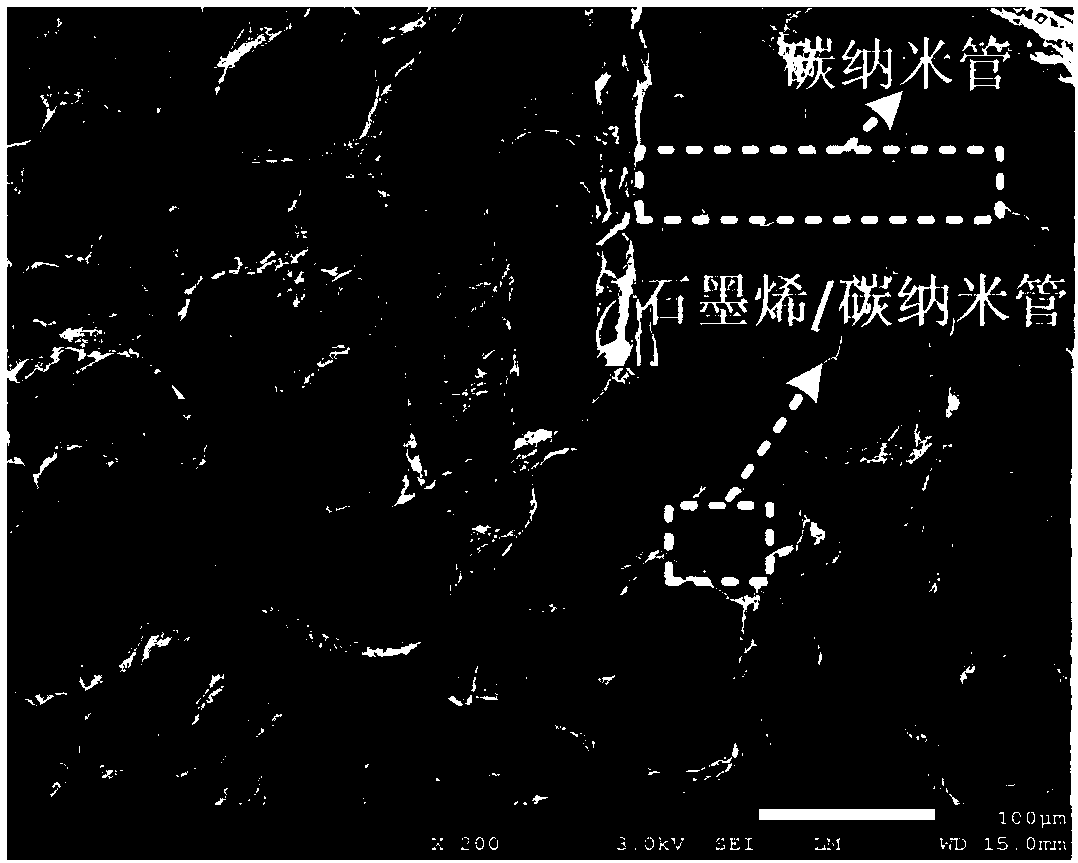

[0038] A silicon rubber / graphene / carbon nanotube nanocomposite material for electromagnetic shielding. The three-dimensional conductive network skeleton of the composite material is a three-dimensional continuous porous material interwoven with graphene and carbon nanotubes, and its composition is an addition liquid 100 parts by mass of silicone rubber (Momentive RTV615, base resin:curing agent=10:1), 0.5 part by mass of graphene, and 0.1 part by mass of single-walled carbon nanotubes (TNSAR, Chengdu Institute of Organic Chemistry). The composite material is prepared by the following steps:

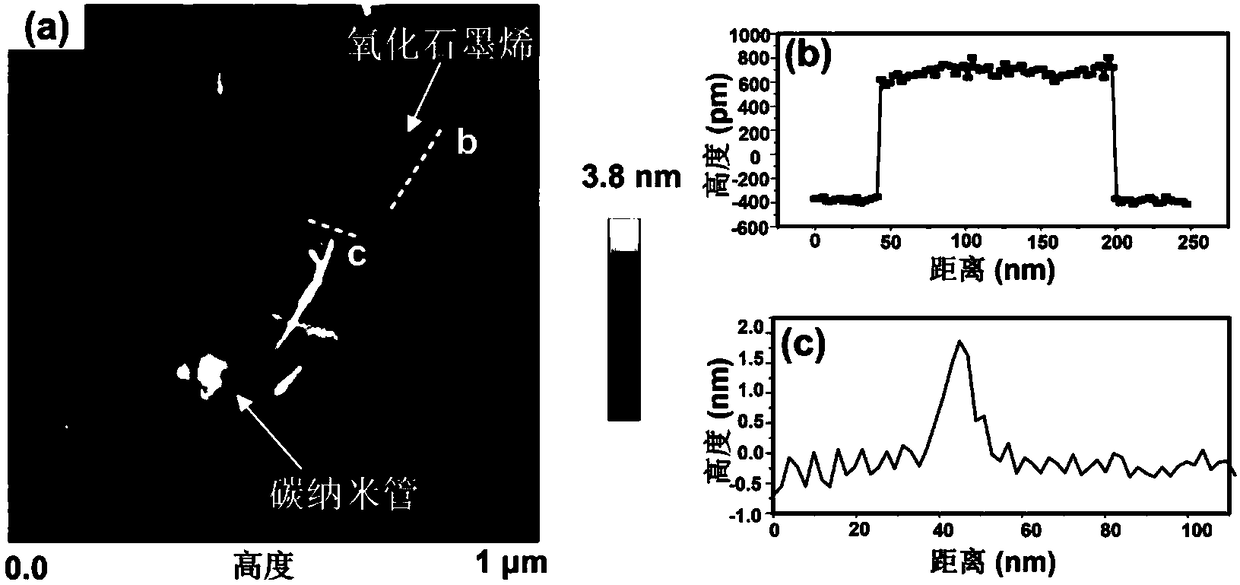

[0039] 1) Graphite oxide was prepared by the Hummers method, and then water was used as a medium to prepare a graphene oxide aqueous dispersion by ultrasonically exfoliating graphite oxide. The concentration of graphite oxide is 10mg / ml, and the ultrasonic treatment condition is 200W / 250kHz / 30min.

[0040] 2) adding the single-walled carbon nanotubes into the graphene oxide aqueous dispe...

Embodiment 2

[0048] A silicon rubber / graphene / carbon nanotube nanocomposite material for electromagnetic shielding. The three-dimensional conductive network skeleton of the composite material is a three-dimensional continuous porous material interwoven with graphene and carbon nanotubes, and its composition is an addition liquid 100 parts by mass of silicone rubber (Momentive RTV615, base resin:curing agent=10:1), 0.5 part by mass of graphene, and 0.1 part by mass of single-walled carbon nanotubes (TNSAR, Chengdu Institute of Organic Chemistry). This composite material adopts the steps similar to embodiment 1 to prepare, and difference is:

[0049] In step 1), high-speed stirring is used instead of ultrasonically exfoliating graphite oxide to prepare a graphene oxide aqueous dispersion. The high-speed stirring condition is 5000rpm / 60min.

[0050] In step 2), high-speed stirring is used instead of ultrasound to prepare the graphene oxide / single-walled carbon nanotube hybrid particle aqueou...

Embodiment 3

[0053] A silicon rubber / graphene / carbon nanotube nanocomposite material for electromagnetic shielding. The three-dimensional conductive network skeleton of the composite material is a three-dimensional continuous porous material interwoven with graphene and carbon nanotubes, and its composition is an addition liquid 100 parts by mass of silicone rubber (Momentive RTV615, matrix resin:curing agent=10:1), 0.5 part by mass of graphene, and 0.1 part by mass of multi-walled carbon nanotubes (TNGM2 of Chengdu Institute of Organic Chemistry). The composite material was prepared by the same steps as in Example 1.

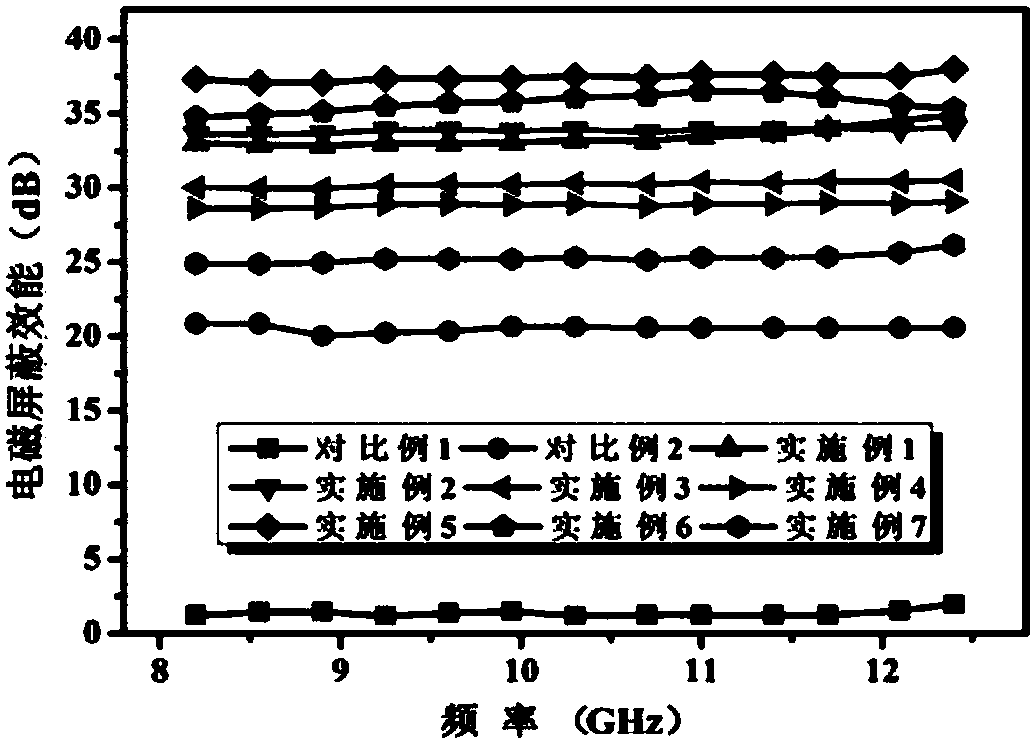

[0054] The conductivity of the silicone rubber / graphene / multi-walled carbon nanotube nanocomposite is 287S / m, and the electromagnetic shielding effectiveness of the X-band is 30dB ( figure 1 ). Compared with Example 1, multi-wall carbon nanotubes are not as effective as single-wall carbon nanotubes in improving the electrical conductivity and electromagnetic shielding perf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Electromagnetic shielding effectiveness | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com