Fly ash microsphere-doped C70 high-performance graphene oxide concrete and preparation method thereof

A technology of fly ash and graphene, applied in the direction of chemical instruments and methods, inorganic chemistry, manufacturing tools, etc., can solve the limited effect of concrete strength and durability, cannot fundamentally improve the gel microstructure, and does not improve cement Hydration capacity and other issues, to achieve the effects of super-high-rise pumping, improved pumpability, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

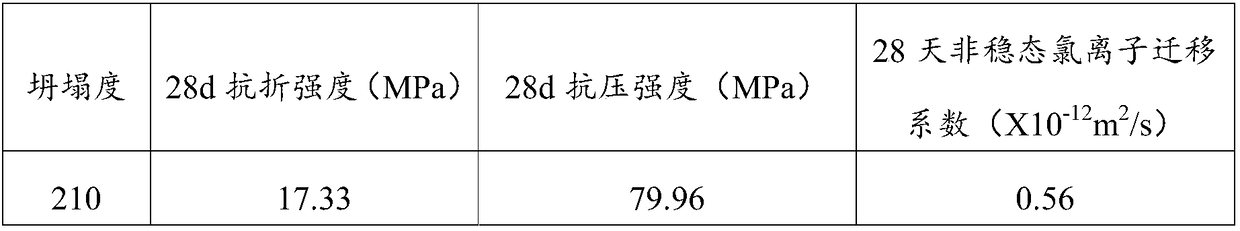

Examples

Embodiment Construction

[0032] The idea, specific structure and technical effects of the present invention will be clearly and completely described below in conjunction with the embodiments, so as to fully understand the purpose, features and effects of the present invention. Apparently, the described embodiments are only some of the embodiments of the present invention, rather than all of them. Based on the embodiments of the present invention, other embodiments obtained by those skilled in the art without creative efforts belong to The protection scope of the present invention. The various technical features in the invention can be combined interactively on the premise of not conflicting with each other.

[0033] A preparation method of C70 high-performance graphene oxide concrete mixed with micropearl fly ash, comprising the steps of:

[0034] (1) Add 9.22 parts of polycarboxylate high-performance water reducer to 166 parts of water, stir evenly for 90 seconds, and record it as solution 1.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com