Preparation method for low-temperature sintered type ceramic glass

A glass-ceramic and low-temperature sintering technology, which is applied in glass manufacturing equipment, glass molding, manufacturing tools, etc., can solve the problems of poor crystal size uniformity of ordinary glass-ceramics, failure to meet the requirements of the glass market, and intensified erosion of refractory materials. Achieve the effects of improving low-temperature sintering and mechanical properties, reducing viscosity, and reducing softening temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

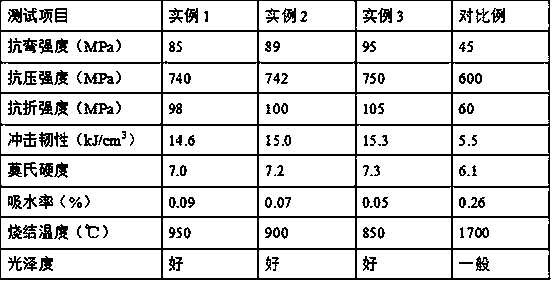

Examples

example 1

[0025] Weigh 1.0kg of urban sludge and pour it into a centrifuge, centrifuge at a speed of 7000r / min for 16min, separate the precipitate, and place the precipitate in an oven, dry at a temperature of 95°C for 35min, and discharge at a constant weight , to obtain a dry precipitate, and then put the dry precipitate into a muffle furnace, calcined at a temperature of 750 ° C for 1 hour, and naturally cooled to room temperature to obtain a calcined precipitate, continue to pour the calcined precipitate into the Mix and mill 0.8% zirconia in a ball mill tank for 3 hours, pass through a 120-mesh sieve after ball milling to obtain a precipitate powder; weigh 24g of ultra-fine alumina with a particle size of 85nm and pour it into a solution containing 2g sodium lauryl sulfate and 80mL Mix and stir in a beaker of deionized water for 20 minutes to obtain an ultrafine alumina dispersion. The ultrafine alumina dispersion, deionized water and absolute ethanol are mixed in a condenser tube w...

example 2

[0027] Weigh 1.1kg of urban sludge and pour it into a centrifuge, centrifuge at a speed of 7500r / min for 18 minutes, separate the precipitate, and place the precipitate in an oven, dry it at a temperature of 97°C for 40 minutes, and discharge it at a constant weight , to obtain a dry precipitate, and then put the dry precipitate into a muffle furnace, calcined at a temperature of 800 ° C for 2 hours, and naturally cooled to room temperature to obtain a calcined precipitate, continue to pour the calcined precipitate into the Mix 0.8% zirconia in a ball mill jar and mill for 4 hours, pass through a 120-mesh sieve after ball milling to obtain a precipitate powder; weigh 26g of superfine alumina with a particle size of 88nm and pour it into a mixture of 3g sodium lauryl sulfate and 87mL Mix and stir in a beaker of deionized water for 22 minutes to obtain a superfine alumina dispersion. The superfine alumina dispersion, deionized water and absolute ethanol are mixed at a volume rati...

example 3

[0029]Weigh 1.2kg of urban sludge and pour it into a centrifuge, centrifuge at a speed of 8000r / min for 20min, separate the precipitate, and place the precipitate in an oven, dry at 100°C for 45min, and discharge at a constant weight , to obtain a dry precipitate, and then put the dry precipitate into a muffle furnace, calcined at a temperature of 850 ° C for 3 hours, and naturally cooled to room temperature to obtain a calcined precipitate, continue to pour the calcined precipitate into the Mix and mill 0.8% zirconia in a ball mill tank for 5 hours, pass through a 120-mesh sieve after ball milling, and obtain a precipitate powder; weigh 30g of ultrafine alumina with a particle size of 90nm and pour it into a solution containing 4g sodium lauryl sulfate and 95mL Mix and stir in a beaker of deionized water for 24 minutes to obtain a superfine alumina dispersion. The superfine alumina dispersion, deionized water and absolute ethanol are mixed at a volume ratio of 5:2:1 and placed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com