Silicon briquette machining method

A processing method and technology for silicon blocks, which are applied to the processing of silicon blocks and ingot polycrystalline processing, can solve the problems of large fluctuations in cutting quality, waste of silicon materials and steel wires, and increased costs, so as to solve the problems of diamond wear and fall off, The effect of comprehensive wire reduction and good processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

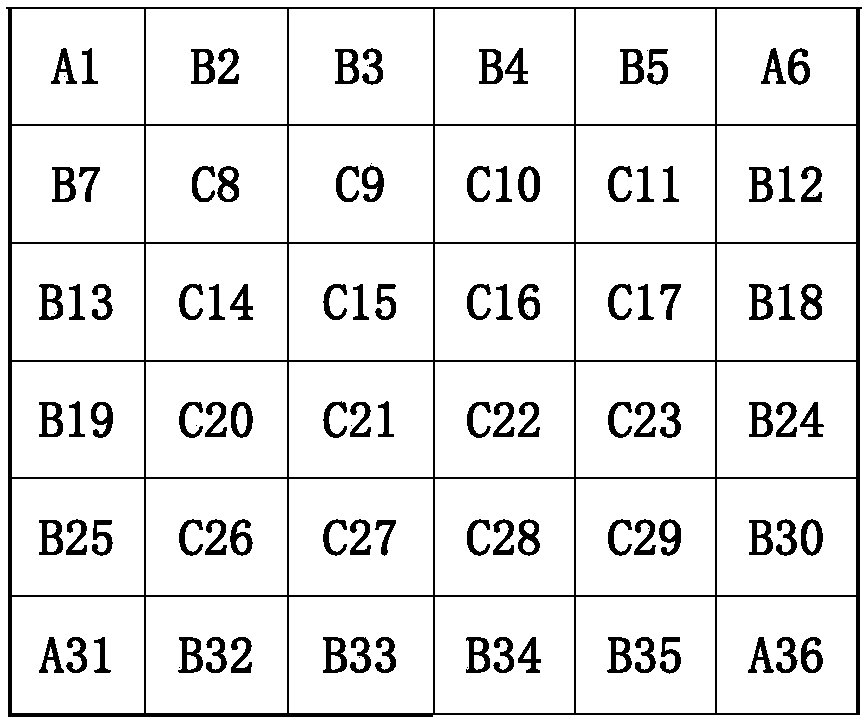

[0052] First, select the G6 ingot, and cut the polycrystalline ingot to obtain 36 silicon square rods of the same size (for a schematic diagram, see figure 1 , A, B and C series labels in the figure indicate that the contact surfaces with the crucible during ingot preparation are two surfaces, one surface and zero surface respectively).

[0053] A1

B2

B3

B4

B5

A6

B7

C8

C9

C10

C11

B12

B13

C14

C15

C16

C17

B18

B19

C20

C21

C22

C23

B24

B25

C26

C27

C28

C29

B30

A31

B32

B33

B34

B35

A36

[0054] Secondly, the micro-Vickers hardness of the above 36 silicon rods was respectively tested using a Vickers micro-hardness tester.

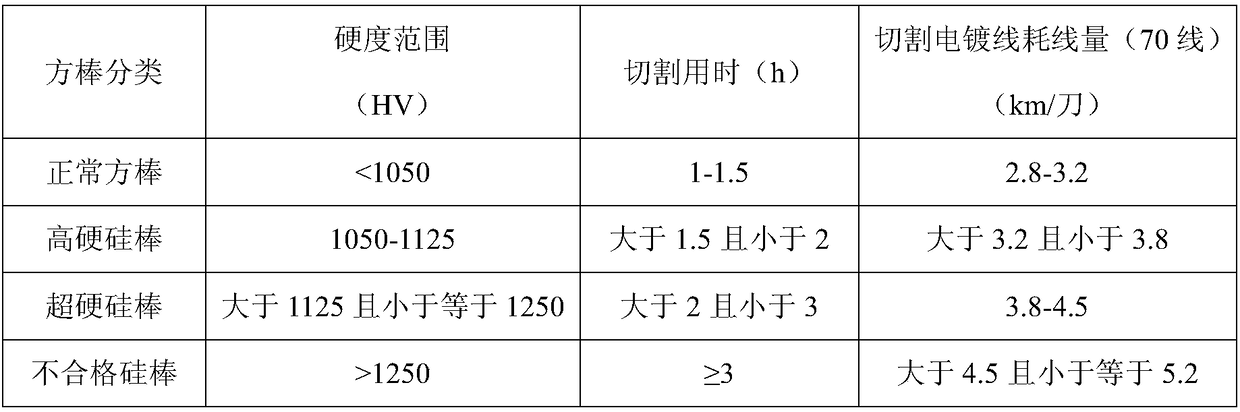

[0055] Again, the square bars are classified according to the test values of the above 36 square bars (see Table 2 for details).

[0056] Then, formulate the corresponding cutting process according to the hardness classification (s...

Embodiment 2

[0069] Except for the following content, other content is identical with embodiment 1:

[0070] After the cutting is completed, the steps of mechanical energy degumming, cleaning and sorting are carried out to complete the processing of polycrystalline diamond wire slices.

[0071] This embodiment also has excellent effects similar to those of Embodiment 1, and the obtained slices are of high quality and have less overall wire consumption.

Embodiment 3

[0073] The hardness of the G6 ingot is detected by conventional methods in the prior art, and then a corresponding cutting process is specified according to the hardness value to perform diamond wire slicing.

[0074] The relationship between cutting process and ingot hardness is as follows:

[0075] If the hardness of the ingot is less than 1050HV, the cutting time is 1h-1.5h, and the consumption of diamond wire for cutting is 2.8km / knife-3.2km / knife;

[0076] If the hardness of the ingot is 1050HV-1125HV, the cutting time is greater than 1.5h and less than 2h, and the consumption of diamond wire for cutting is greater than 3.2km / knife and less than 3.8km / knife;

[0077] If the hardness of the ingot is greater than 1125HV and less than or equal to 1250HV, the cutting time is 2h-3h, and the consumption of diamond wire for cutting is 3.8km / knife-4.5km / knife;

[0078] If the hardness of the ingot is >1250HV, the cutting time is >3h, and the consumption of diamond wire for cutti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com