Polycrystalline silicon wafer cleaning system and cleaning method thereof

A polycrystalline silicon wafer and cleaning system technology, applied in the field of solar photovoltaics, can solve problems affecting the cleanliness of the texturing tank, polluting the chemical reagents in the texturing tank, and affecting the corrosion rate of the texturing tank, achieving better cleaning effects, shortening the process time, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

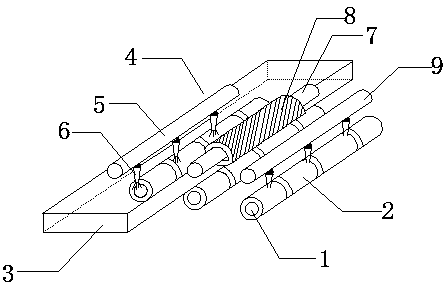

[0032] A polysilicon wafer cleaning system, used for the cleaning of polysilicon wafers before the texturing process, such as figure 1 As shown, it is located on the box body and is fixedly arranged at the pre-sequence station of the texturing tank. The polysilicon wafer cleaning system includes a loading station, a cleaning station and an unloading station. Both the feeding station and the unloading station realize the connection of each station by means of the conveying device, and the polysilicon wafer can enter the texturing tank from the unloading station through the conveying device, and the cleaning station is provided with spraying nozzles in sequence Spraying device, wiping device and drying device, and the spraying device, wiping device and drying device are connected by conveying device;

[0033] The polysilicon wafer cleaning system also includes a control device (not shown in the figure) arranged below the box; the conveying device, the spraying device, the wiping...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com