A new type of titanium dioxide particulate material, its preparation method, and its application in the field of environmental protection

A technology of titanium dioxide and porous titanium dioxide, applied in the directions of titanium dioxide, chemical instruments and methods, titanium oxide/hydroxide, etc., can solve the problems of difficult to achieve solid-liquid separation of nanoparticles, unfavorable adsorption and catalysis, small particle size, etc. Good static adsorption performance, excellent adsorption capacity and large adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0073] The present invention provides a kind of preparation method of titania particle material, comprises the following steps:

[0074] 1) After mixing the titanium source and the solvent, a precursor solution is obtained;

[0075] 2) spraying the precursor liquid obtained in the above steps through microfluidics, and drying to obtain particles;

[0076] 3) After the particles obtained in the above steps are heat-treated, titanium dioxide particulate material is obtained.

[0077] The present invention can correspond to the performance and structure of the titanium dioxide particulate material in the above preparation method, as well as the corresponding optimization principles, and the corresponding performance and structure of the titanium dioxide particulate material, as well as the corresponding optimization principles, and will not repeat them here. .

[0078] The invention firstly mixes the titanium source and the solvent to obtain the precursor liquid.

[0079] The ...

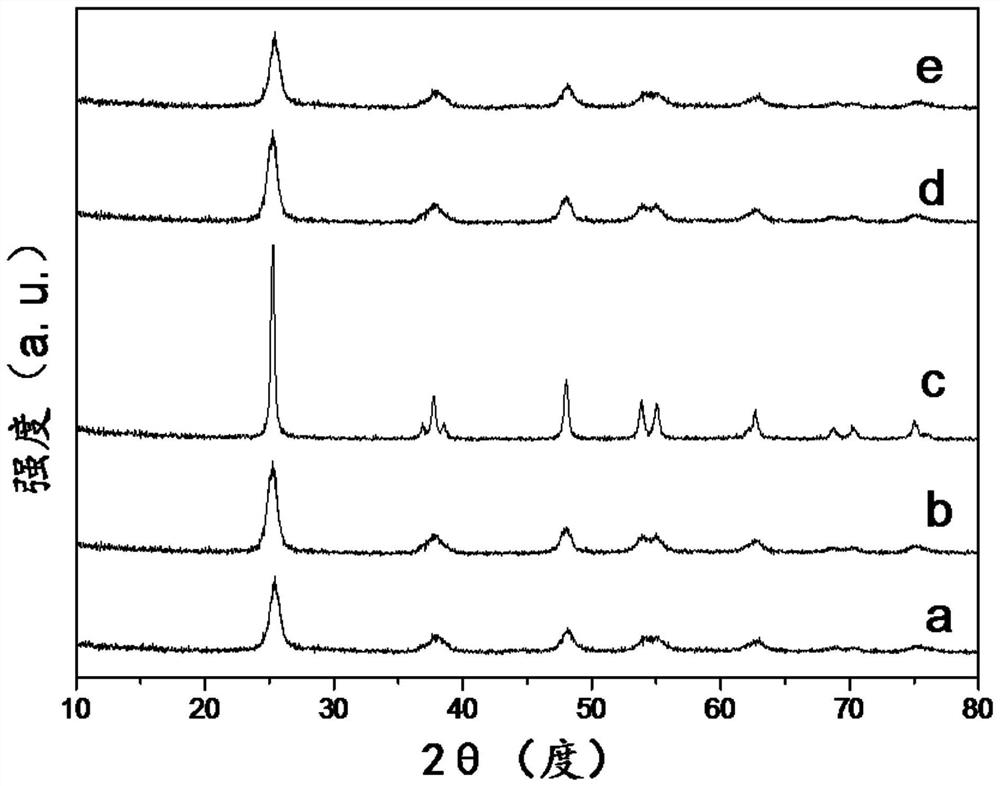

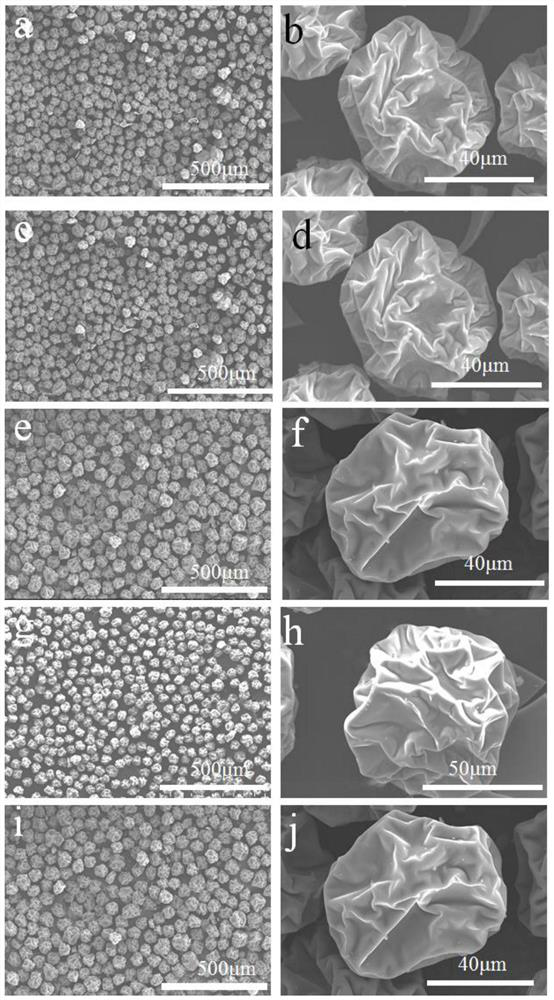

Embodiment 1

[0114] Dissolve F127 (8.0 g) in 120 ml of absolute ethanol, add 16 ml of concentrated hydrochloric acid, and stir at 35° C. and 350 rpm for 30 minutes to obtain a clear solution. Subsequently, 24 g of titanium isopropoxide was added, and the stirring was continued for 30 minutes to obtain a light yellow clear solution, which was the precursor solution. Subsequently, microfluidic spray drying was used for granulation, spray drying was carried out under the conditions of a nozzle size of 75 μm and a spray temperature of 150° C., and the obtained particles were calcined at 350° C. in a muffle furnace to obtain sample 1.

Embodiment 2

[0116] The muffle furnace calcination temperature in Example 1 was changed to 400° C., and other operations were the same as in Example 1 to obtain Sample 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com