Nanofiber-nanowire composite and method for its production

A nanofiber, composite technology, applied in the field of nanocomposites, can solve problems such as inconsistent nanoparticle distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

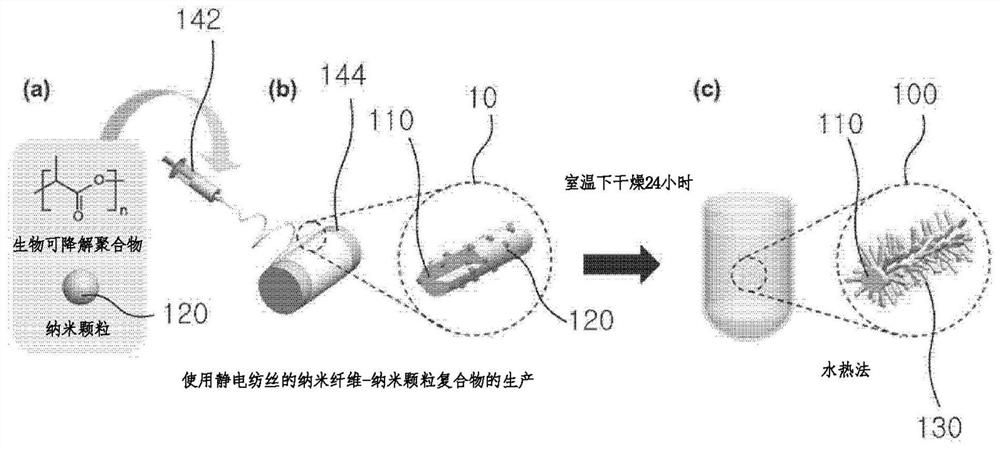

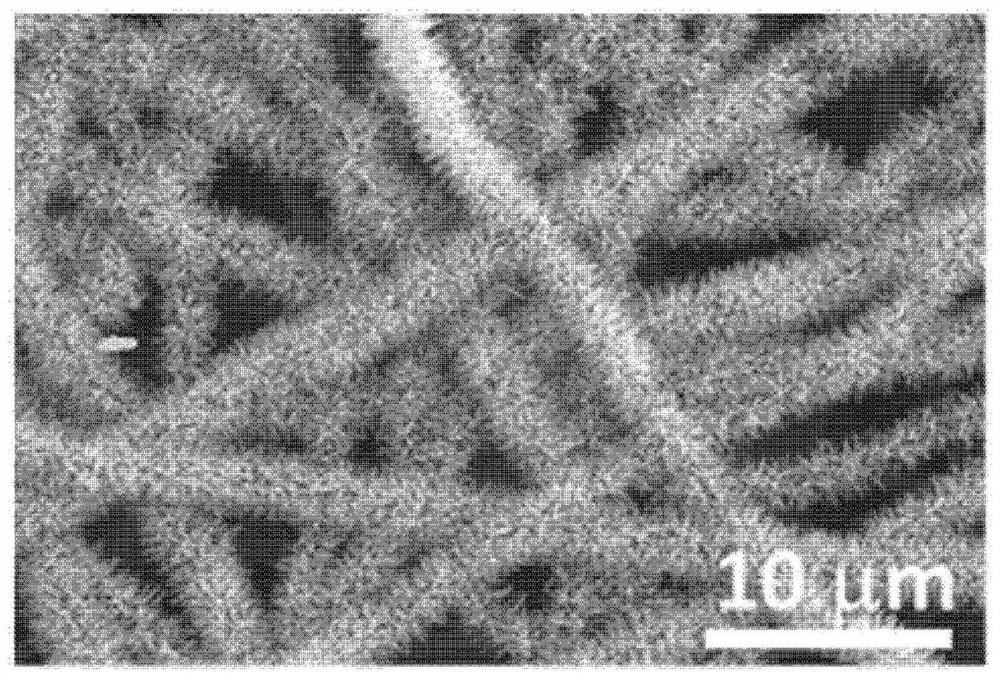

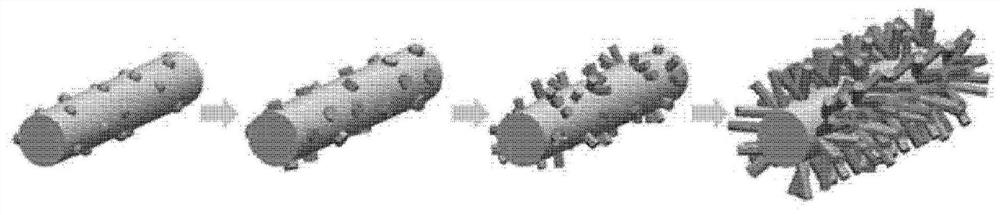

[0037]According to an exemplary embodiment of the present disclosure, the nanofiber-nanoparticle composite is synthesized in an electrospinning synthesis solution into which nanoparticles are injected. Nanofiber-nanoparticle composites are transformed into end-product nanofiber-nanowire composites by growing nanowires from nanoparticles exposed to the surface of the nanofiber-nanoparticle composite via a hydrothermal process. Nanofibers can be easily produced by a hydrothermal method after obtaining nanofiber-nanoparticle composites (in which nanoparticles are uniformly contained) by electrospinning an electrospinning synthesis solution in which nanoparticles are uniformly distributed- nanowire composites.

[0038] According to the exemplary embodiment of the present disclosure, no additional processing, such as heat treatment, performed in conventional methods is required. That is, it is possible to produce composites with higher productivity and uniformity than those produc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com