Plasma jet deposition film device and method of shallowing surface trap level

A plasma and jet deposition technology, applied in the field of electrochemistry, can solve the problems of hindering charge injection and high energy consumption of ion implantation, and achieve the effects of reducing initial charge density, large discharge area and short deposition time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

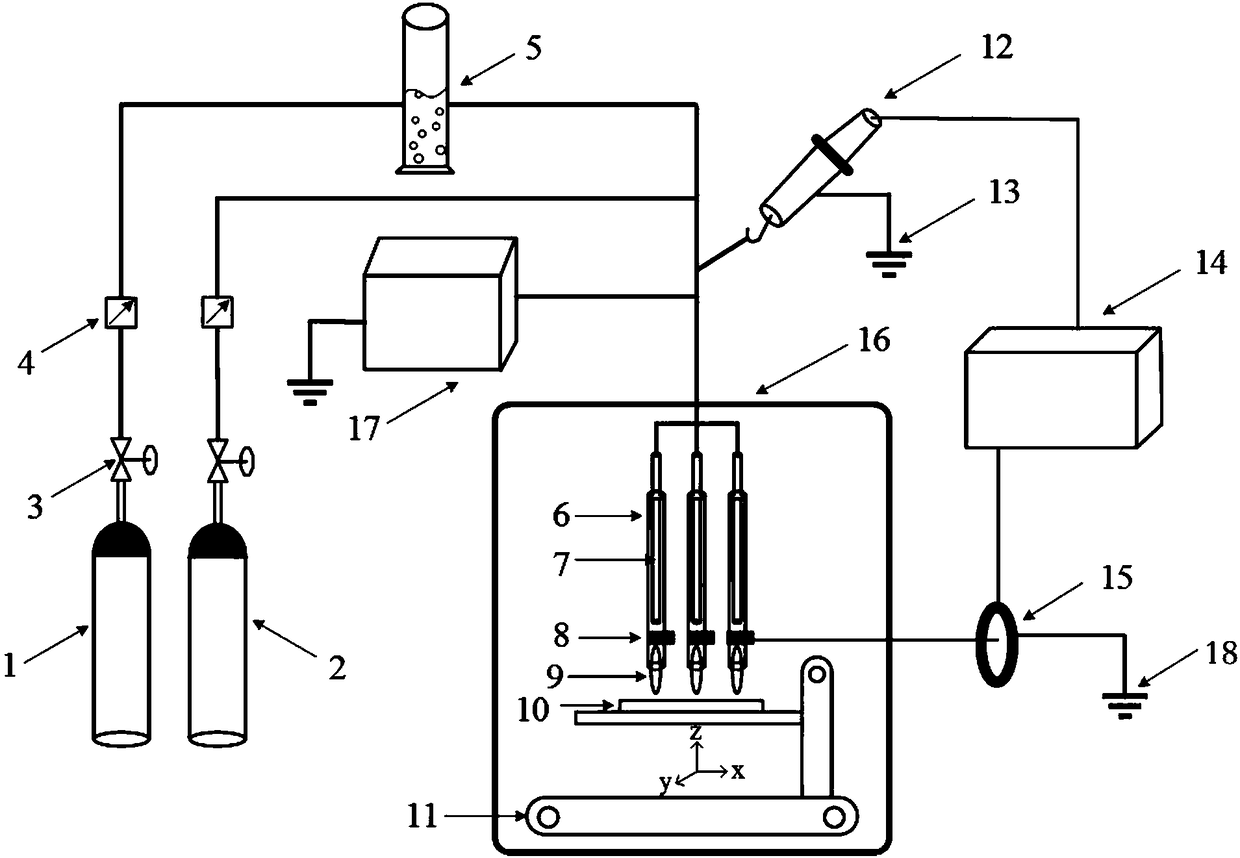

[0030] Such as figure 1 As shown, what Embodiment 1 of the present invention described is a kind of plasma jet deposition film device, and this device comprises:

[0031] A plasma jet array, which is placed in a tempered glass cavity 16, and the plasma jet array includes a quartz tube 6, a hollow metal capillary 7, copper foil 8 and a three-dimensional mobile platform 11;

[0032] The hollow metal capillary 7 is inserted in the quartz tube 6, and the outer wall of the hollow metal capillary 7 is not in contact with the inner wall of the quartz tube 6, and the lower nozzle of the hollow metal capillary 7 is located above the lower nozzle of the quartz tube 6; the quartz tube selected in this embodiment 6 The outer diameter is 4mm, the inner diameter is 2mm, the wall thickness is 1mm, and the length is 180mm. The hollow metal capillary is made of stainless steel. The lower nozzle of the metal capillary 7 is located 35 mm above the lower nozzle of the quartz tube 6 . In differe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com