Method for promoting phosphorus enrichment phase particles in dephosphorization slag to be conglomerated and grow up

A technology of particle aggregation and enrichment phase, applied in the direction of improving process efficiency, can solve the problems of small particles, accelerated mutual aggregation of phosphorus-enriched phase particles, poor magnetic separation effect, etc., to achieve simple operation, simple and convenient operation, real results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

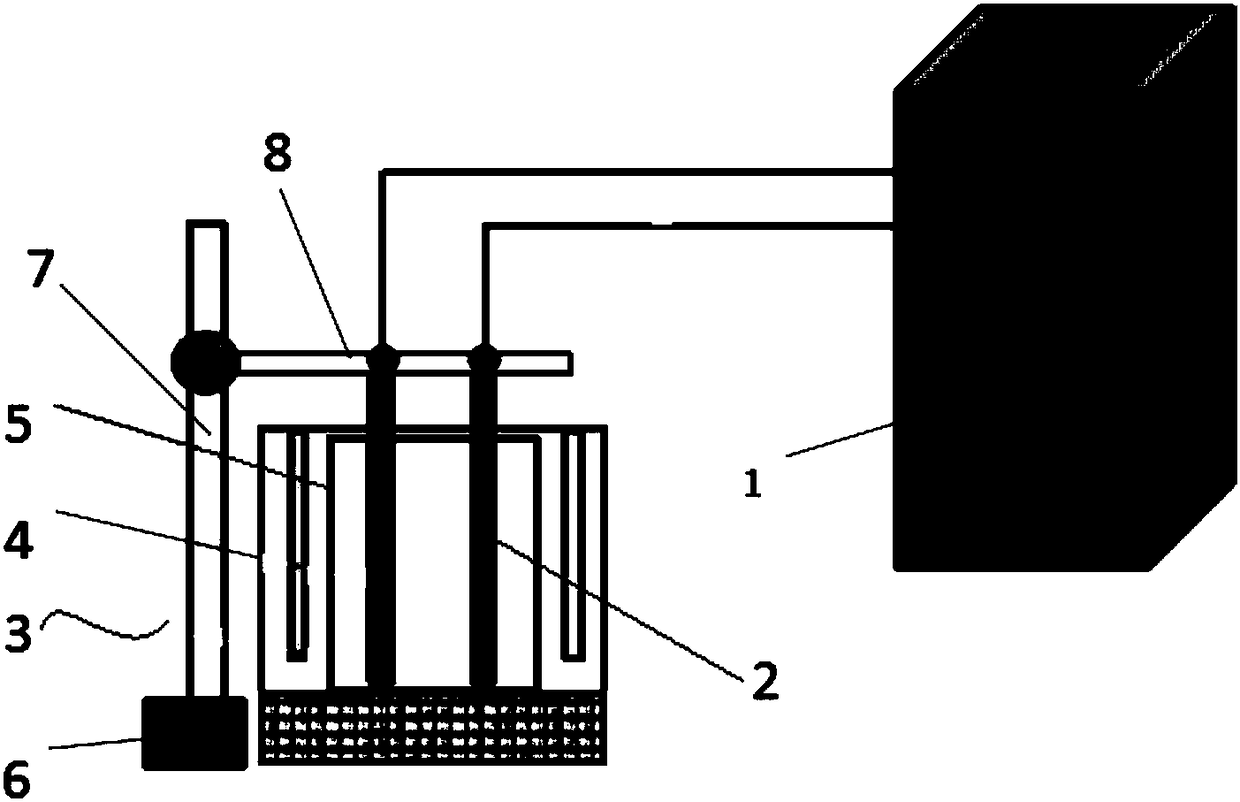

[0056] See attached figure 1 , the present invention is a device for promoting the aggregation and growth of phosphorus-enriched phase particles in dephosphorization slag, the shown device includes an electric pulse generating system and a heating furnace 4; the shown electric pulse generating system consists of an electric pulse generator 1, an electrode 2, The electrode bracket 3 is composed of; the heating furnace 4 is provided with a crucible 5, the electrode 2 is installed on the electrode bracket 3, one end is electrically connected with the electric pulse generator 1, and the other end extends into the crucible 5; the electrode bracket 3 It consists of a base 6, a vertical bar 7, and a cross bar 8. The vertical bar 7 is vertically installed on the base 6. One end of the cross bar 8 is movably connected with the vertical bar 7, and the other end is installed with an electrode 2

[0057] There are two electrodes, which are installed on the cross bar 8, and the distance be...

Embodiment 2

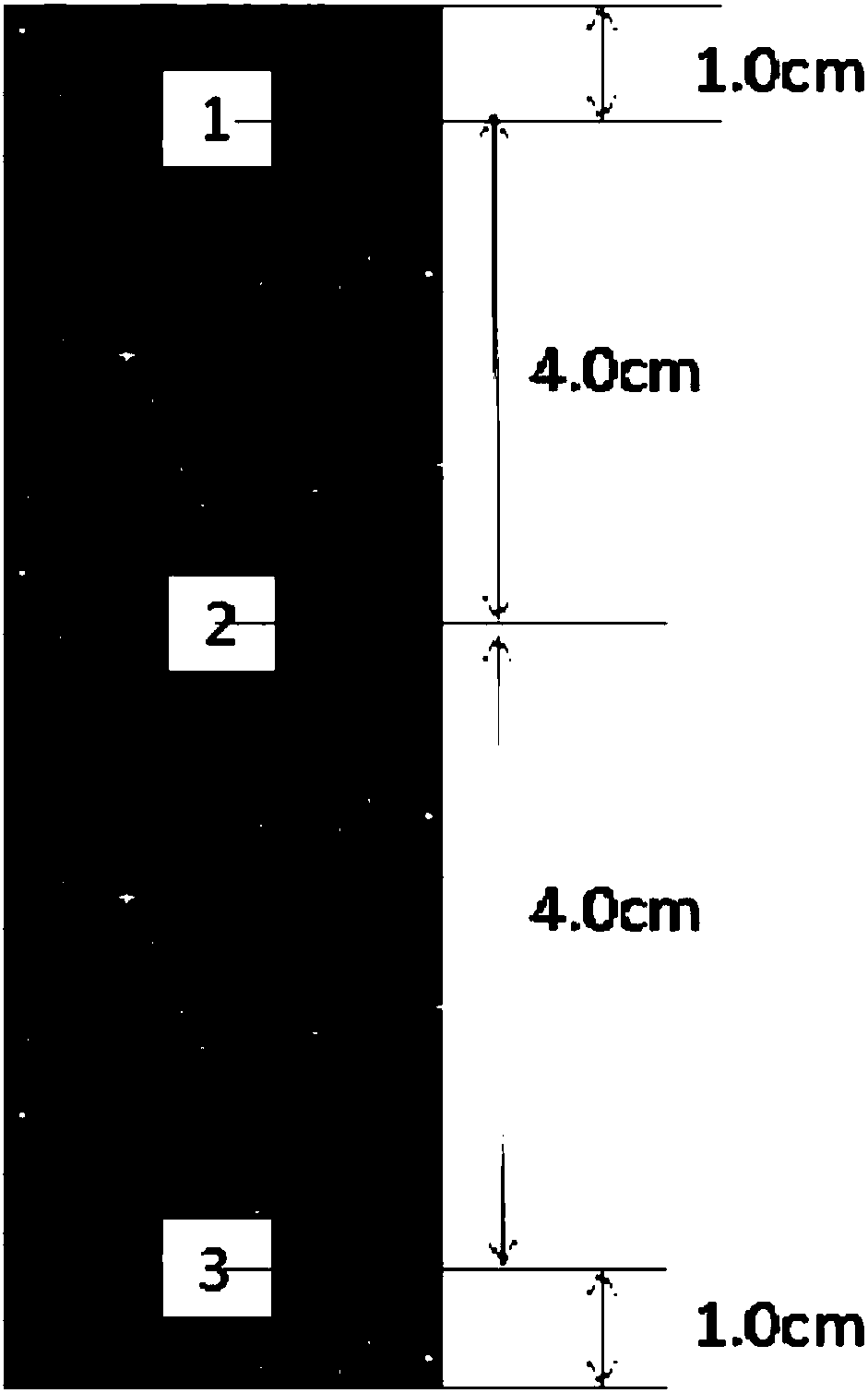

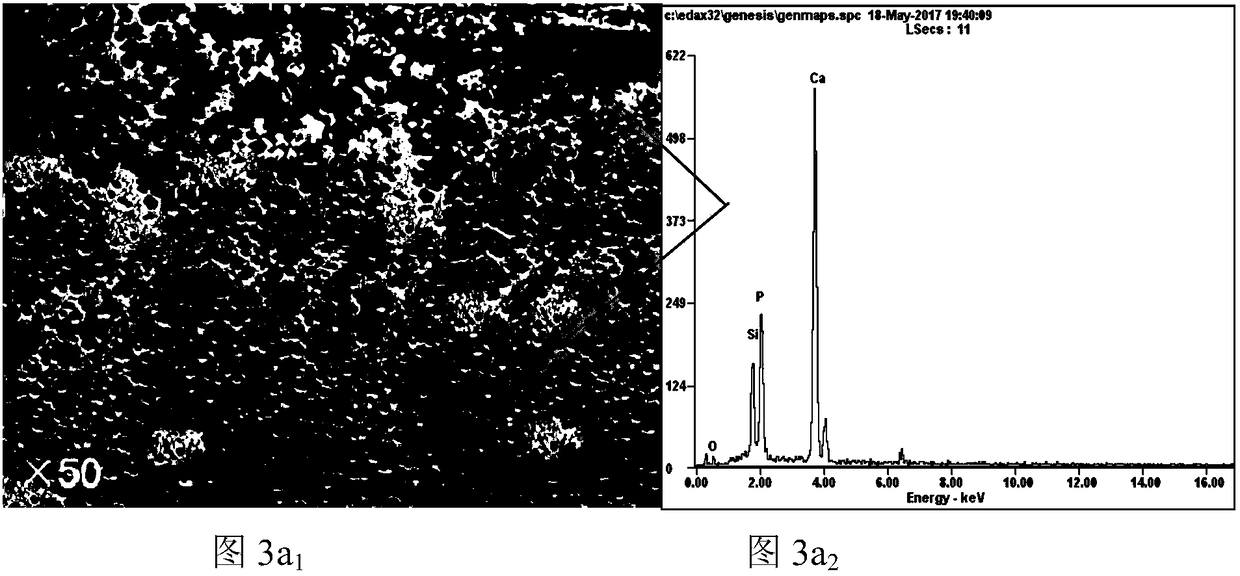

[0060] A method for promoting the aggregation and growth of phosphorus-enriched phase particles in dephosphorization slag is to place the slag sample in the crucible of the device for promoting the aggregation and growth of phosphorus-enriched phase particles in dephosphorization slag described in Example 1, and heat After the slag sample is melted, the temperature is lowered at a cooling rate of 9-12°C / min until a solid phase appears in the melt, then the cooling is stopped, and the temperature is maintained at this temperature to obtain a multiphase slag system in which solid and liquid phases coexist. The slag system refers to a two-phase system in which only the phosphorus-enriched phase is a solid phase and the rest of the components are a liquid phase; then, insert electrodes into the melt, adjust the distance between electrodes and the depth of insertion into the melt, and start the electric pulse generator to After applying a pulse current to the electrode for at least ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com