Aqueous antistatic acrylate waterproof coating and preparation method thereof

An acrylate and waterproof coating technology, applied in conductive coatings, coatings, etc., can solve problems such as poor antistatic properties, unsatisfactory mechanical properties, and limit the promotion and application of coatings, and achieve the effect of excellent electrical conductivity and mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The preparation method of above-mentioned a kind of waterborne antistatic acrylate waterproof paint comprises the following steps:

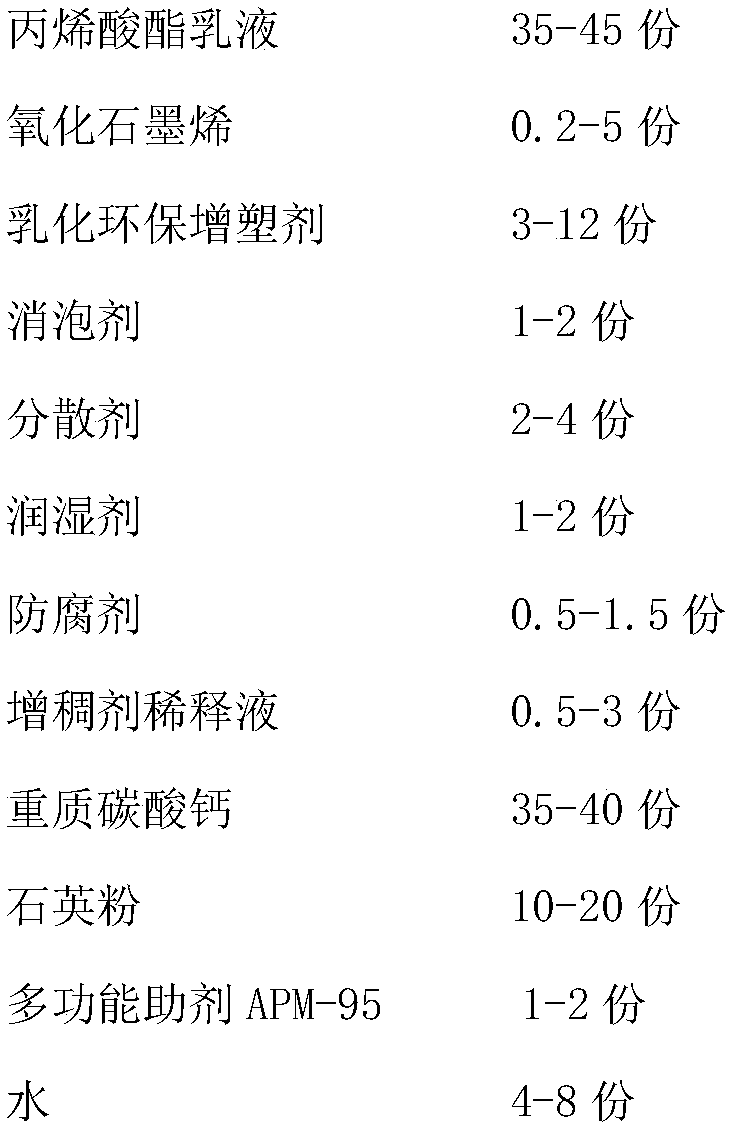

[0034] (1) In terms of parts by mass, take 40 parts of acrylate emulsion, 3 parts of graphene oxide, 7 parts of emulsified environmental protection plasticizer, 1.5 parts of defoamer, 3 parts of dispersant, 1.5 parts of wetting agent, 1.5 parts of more Functional additive APM-95, 1 part of preservative, 1.5 parts of thickener diluent, 37 parts of heavy calcium carbonate, 15 parts of quartz powder and 6 parts of water, set aside;

[0035] (2) Add graphene oxide and water into the dispersion tank and stir evenly, then add acrylate emulsion, defoamer, dispersant, wetting agent, multifunctional additive APM-95 and preservative in turn, and 400r / min Stir at a high speed for 15 minutes, then slowly add emulsified environmentally friendly plasticizers, keep the speed constant, continue stirring for 10 minutes, increase the speed to 1000r / min, and...

Embodiment 2

[0037] The preparation method of above-mentioned a kind of waterborne antistatic acrylate waterproof paint comprises the following steps:

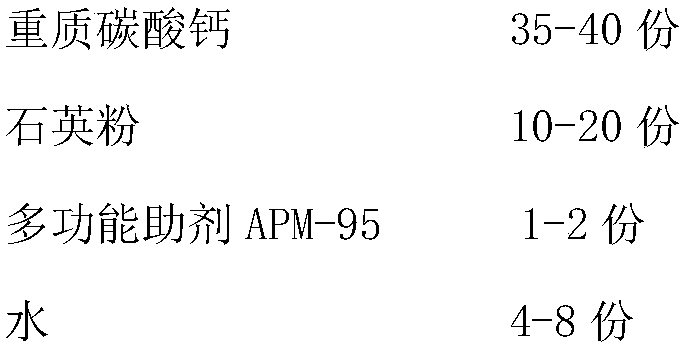

[0038] (1) In terms of parts by mass, take 35 parts of acrylate emulsion, 0.2 parts of graphene oxide, 3 parts of emulsified environmental protection plasticizer, 1 part of defoamer, 2 parts of dispersant, 1 part of wetting agent, and 1 part of more Functional additive APM-95, 0.5 parts of antiseptic, 0.5 parts of thickener diluent, 35 parts of heavy calcium carbonate, 10 parts of quartz powder and 4 parts of water, set aside;

[0039] (2) Add graphene oxide and water into the dispersion tank and stir evenly, then add acrylate emulsion, defoamer, dispersant, wetting agent, multifunctional additive APM-95 and preservative in turn, and 300r / min Stir at a high speed for 15 minutes, then slowly add emulsified environmentally friendly plasticizers, keep the speed constant, continue to stir for 10 minutes, increase the speed to 900r / min, and sti...

Embodiment 3

[0041] The preparation method of above-mentioned a kind of waterborne antistatic acrylate waterproof paint comprises the following steps:

[0042] (1) In terms of parts by mass, take 45 parts of acrylate emulsion, 5 parts of graphene oxide, 12 parts of emulsified environmental protection plasticizer, 2 parts of defoamer, 4 parts of dispersant, 2 parts of wetting agent, 2 parts of more Functional additive APM-95, 1.5 parts of antiseptic, 3 parts of thickener diluent, 40 parts of heavy calcium carbonate, 20 parts of quartz powder and 8 parts of water, set aside;

[0043] (2) Add graphene oxide and water into the dispersion tank and stir evenly, then add acrylate emulsion, defoamer, dispersant, wetting agent, multifunctional additive APM-95 and preservative in sequence, and with 500r / min Stir at a high speed for 15 minutes, then slowly add emulsified environmentally friendly plasticizers, keep the speed constant, continue stirring for 10 minutes, increase the speed to 1100r / min, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com