Synthesizing method for pesticide intermediate 4-formyl menthyl valerate

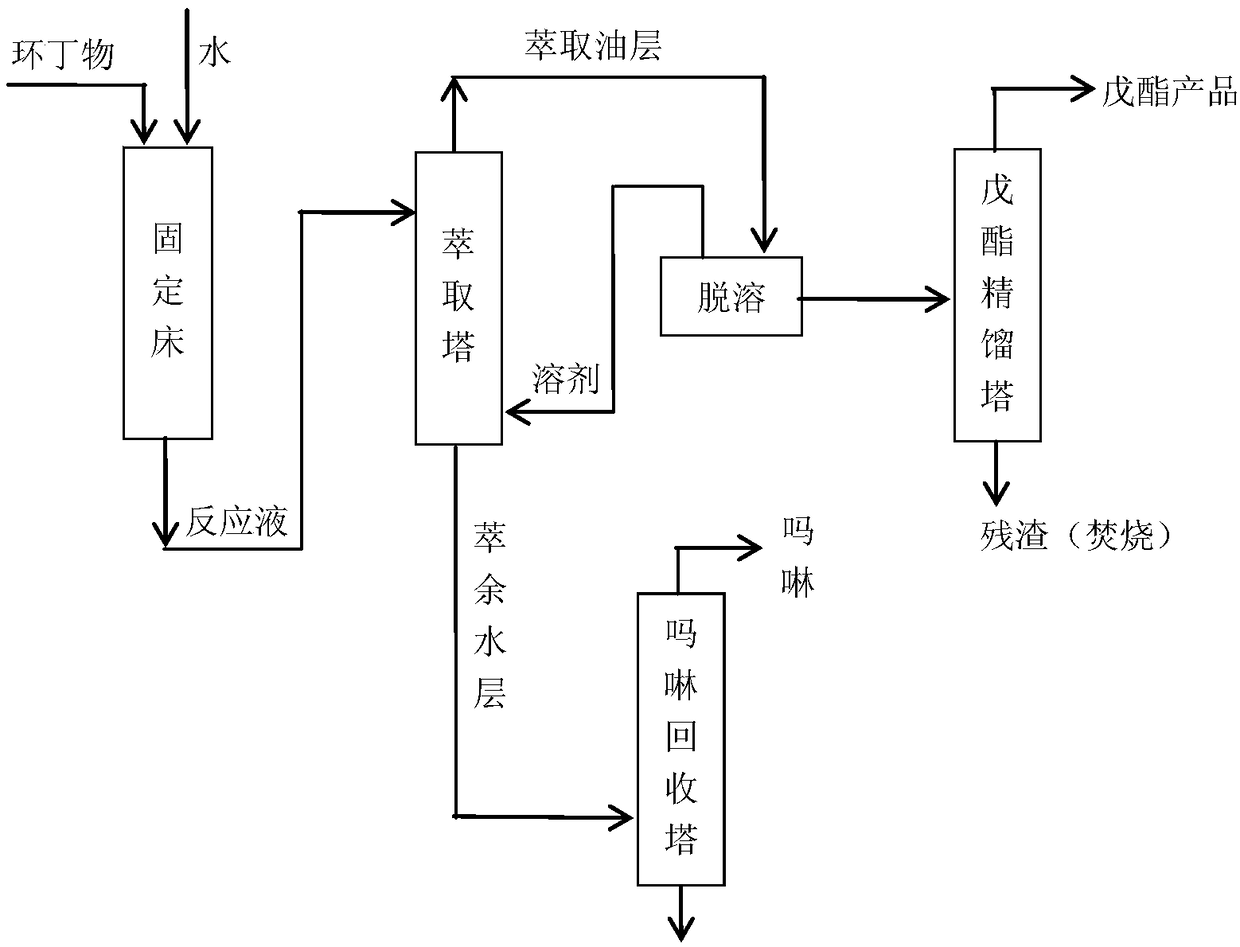

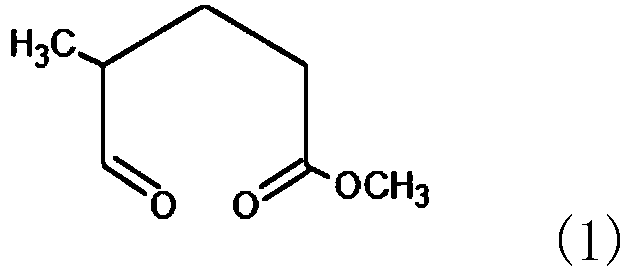

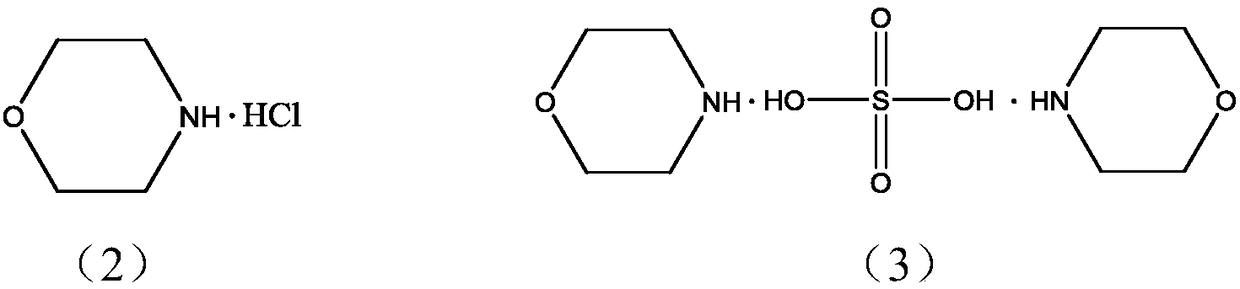

A technology for the synthesis of methyl formyl valerate and a synthesis method, which is applied in the field of synthesis of methyl 4-formyl valerate, a pesticide intermediate, can solve the problems of difficult recovery of raw material morpholine and difficulty in meeting environmental protection requirements, and achieve convenient and continuous The effects of efficient production, easy separation, and convenient recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Preheating

[0031] Add pretreated strong acidic resin D072 and deionized water to a fixed-bed reactor with an inner diameter of 4cm and a height of 40cm. The resin filling height is 32cm (about 300g in weight), and the mixture in the reactor is heated to 50°C; (2) Acid hydrolysis

[0032] After the temperature of the material in the reactor in step (1) is stable, the 755.7g cyclobutane (content 84.56%) and deionized water in the raw material storage tank are continuously injected into the reactor with a metering pump to adjust the space velocity of the cyclobutyl 0.2h -1 , deionized water space velocity 0.2h -1 , control the temperature of the fixed bed at 50°C, the reaction process can be sampled and analyzed, and the cyclobutane content is normalized by gas chromatography to analyze 0.2%; when the reaction liquid sampling gas chromatography analyzes the cyclobutane normalized content > 2%, the resin needs to be regenerated After treatment, it will continue to ...

Embodiment 2

[0037] (1) Preheating

[0038] Add pretreated strong acid resin D072 and deionized water to a fixed-bed reactor with an inner diameter of 4 cm and a height of 40 cm. The resin filling height is 32 cm (weight is about 300 g), and the mixture in the reactor is heated to 75 ° C;

[0039] (2) Acid hydrolysis

[0040] After the temperature of the material in the reactor of step (1) is stable, the 1997.6g cyclobutane (content 85.3%) and deionized water in the raw material storage tank are continuously injected into the reactor with a metering pump, and the space velocity of the cyclobutyl substance is adjusted 1h -1 , deionized water space velocity 0.8h -1 , control the temperature of the fixed bed at 75°C, the reaction process can be sampled and analyzed, and the cyclobutane content is normalized to 0.4% by gas chromatography; when the reaction liquid sampling gas chromatography analyzes the cyclobutane normalized content > 2%, the resin needs to be regenerated After treatment, ...

Embodiment 3

[0045] (1) Preheating

[0046] Add pretreated strong acid resin D072 and deionized water to a fixed-bed reactor with an inner diameter of 4 cm and a height of 40 cm. The resin filling height is 32 cm (weight is about 300 g), and the mixture in the reactor is heated to 65 ° C;

[0047] (2) Acid hydrolysis

[0048] After the temperature of the material in the reactor in step (1) is stable, the 1259.5g cyclobutane (content 84.56%) and deionized water in the raw material storage tank are continuously injected into the reactor with a metering pump to adjust the space velocity of the cyclobutane 0.5h -1 , deionized water space velocity 0.2h -1 , control the fixed bed temperature at 65°C, sample analysis can be done during the reaction, and use gas chromatography to analyze the normalized content of cyclobutane at 0.45%. After treatment, it will continue to be used for acid hydrolysis after regeneration.

[0049] The reaction solution enters the tower from the feed port (20cm awa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com