PVC (polyvinyl chloride) double side compound sound-proof felt and preparation method thereof

A sound-insulating felt and double-sided technology, which is applied in the field of PVC double-sided composite sound-insulating felt and its preparation, can solve the problems of degumming and delamination of the glue bonding layer, the decline of the use function of sound-insulating parts, and non-compliance with environmental protection, so as to achieve protection without Abrasion, elimination of shock and abnormal noise, and improvement of plasticizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Composition and weight percentage of fiber needle felt: flame-retardant polyacrylonitrile staple fiber 60-65%, flame-retardant viscose staple fiber 25-30%, flame-retardant PET staple fiber 5-10%, the sum of each component is 100 %.

[0044] The preparation technology of fiber needle felt, comprises the following steps:

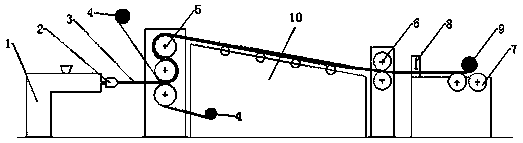

[0045] 1) Ingredients: weigh 20kg as a batch, weigh the three component fiber materials according to the above percentages, and manually disperse and sprinkle them on the conveyor belt. By analogy, the raw materials are continuously weighed in batches and proportionally, and put on the conveyor belt for forward output. Conveyor belt width: 1000mm; Conveyor belt linear speed: 1-10m / min.

[0046] 2) Mixing: Send the raw materials conveyed by the conveyor belt into the opener, and use the comb needle and nail plate on the high-speed rotating opener roller to disperse and disrupt the fiber materials of the three components, and send them to the opener thr...

Embodiment 2

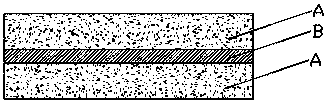

[0053] The formula (parts by weight) of the PVC heavy layer is: 100 parts of PVC resin (type 5), 24-30 parts of DOTP (dioctyl terephthalate), 4-6 parts of CPE (CL 35%), calcium- 5-7 parts of zinc composite stabilizer, 2-4 parts of zinc stearate, 2-4 parts of stearic acid, 2-3 parts of silane coupling agent, 25-50 parts of aluminum hydroxide, 6-8 parts of antimony trioxide 50-75 parts of calcium carbonate, 50-75 parts of barium sulfate, 1-2 parts of carbon black.

[0054] The preparation process of the PVC sheet is as follows: after weighing the raw materials according to the formula, they are mixed in a high-speed mixer, and the mixed powder raw materials are granulated by a granulator for later use. Start the barrel and mold heating device of the PVC sheet extruder. After reaching the set process temperature, start the extrusion motor to make the screw rotate. The extruded sheet melt is extruded quantitatively and at a constant speed through the mold for compounding in subse...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com