Processing method of electromagnetic shielding magnetic material

A technology of electromagnetic shielding and processing methods, which is applied in the manufacture of inductors/transformers/magnets, circuits, electrical components, etc., can solve problems such as large high-frequency losses, abnormal local chip drop holes, and large eddy current effects, and achieve good frequency and temperature Excellent stability, high electromagnetic transmission conversion efficiency, and low high-frequency eddy current loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

[0041] A method for processing magnetic materials for electromagnetic shielding, comprising the following steps:

[0042] Step 1) Winding the soft magnetic alloy magnetic material strip through a mold to form a soft magnetic alloy magnetic material ring 1 with a certain inner and outer diameter; the soft magnetic alloy magnetic material strip is an amorphous nanocrystalline alloy steel strip Or a soft magnetic electrical alloy steel strip; preferably, the amorphous nanocrystalline alloy steel strip is an Fe-based amorphous nanocrystalline alloy steel strip or a Co-based / FeNi-based amorphous nanocrystalline alloy steel strip;

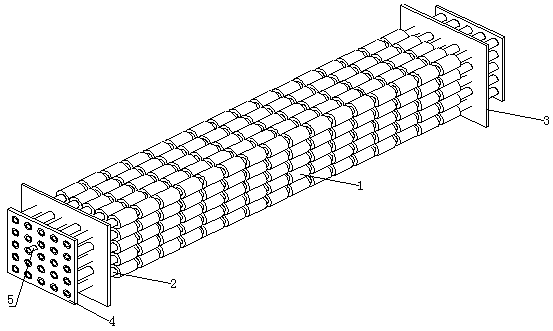

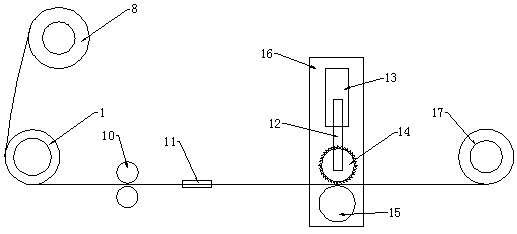

[0043] Step 2) see figure 1 As shown, this step adopts a special charging rack, which includes several vertically placed cylindrical tubes 2, the outer diameter of the cylindrical tubes 2 is slightly smaller ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com