Preparation method of geopolymer-based permeable brick

A technology of permeable bricks and geopolymers, which is applied in the field of preparation of geopolymer-based permeable bricks, and achieves the effects of simple preparation process, low cost and less equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

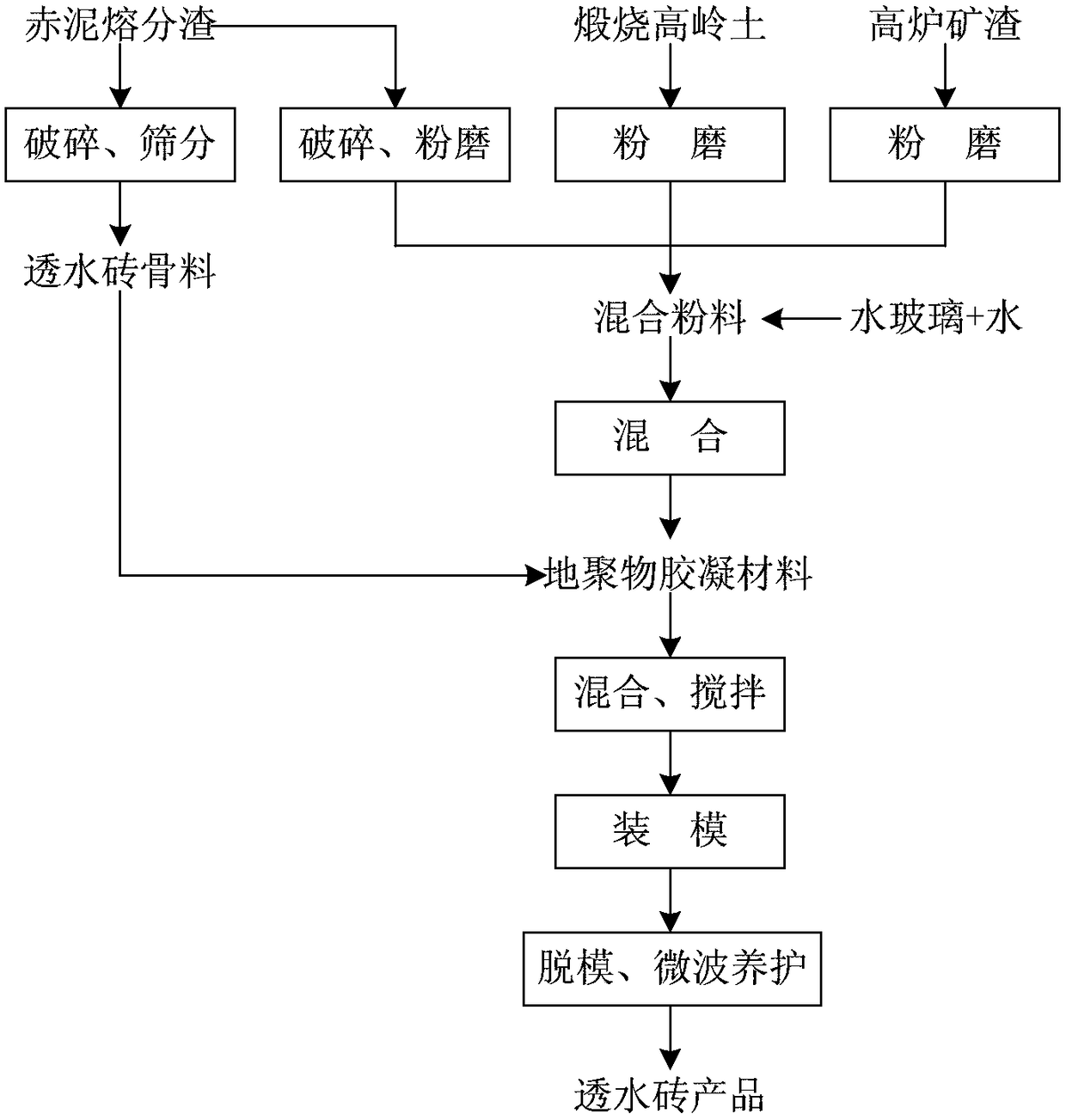

[0035] Such as figure 1 Shown, the present invention provides a kind of preparation method of geopolymer base permeable brick, comprises the following steps:

[0036] (1) Preparation of permeable brick aggregate

[0037] After the first red mud melting slag is crushed and sieved, the permeable brick aggregate with a particle size of 3-5mm is obtained.

[0038] (2) Prepare the gelling material

[0039] Mix the crushed, sieved and ground second red mud slag, the ground calcined kaolin and the ground blast furnace slag according to the mass ratio of 1:(0.4-0.8):(0.1-0.3) , to obtain mixed powder;

[0040] In a preferred embodiment, the particle size of the pulverized second red mud slag is 25-48 μm; the pulverized calcined kaolin and the pulverized blast furnace slag both have a particle size of 25-48 μm. In a preferred embodiment, the activator is technical grade water glass, wherein Na 2 The mass fraction of O is 7.5%-12.8%, SiO 2 The mass fraction is 24.6%-27.6%, and the...

Embodiment 1

[0050] (1) Preparation of permeable brick aggregate

[0051] After the first red mud melting slag is crushed and sieved, the permeable brick aggregate with a particle size of 3-5mm is obtained.

[0052] (2) Prepare the gelling material

[0053] uniformly mixing the crushed, sieved and ground second red mud slag, ground calcined kaolin and ground blast furnace slag at a mass ratio of 1:0.45:0.1 to obtain a mixed powder;

[0054] The particle size of the second red mud slag after grinding is 25-48 μm; the particle size of the calcined kaolin after grinding is 25-48 μm, and the particle size of the blast furnace slag after grinding is 25-48 μm. The activator is industrial grade water glass, where Na 2 The mass fraction of O is 8.75%, SiO 2 The mass fraction is 27.6%, and the modulus is 3.3. When in use, adjust the modulus of the water glass to 1.2 with NaOH.

[0055] (3) Preparation of geopolymer cementitious material

[0056] The mixed powder, the activator and water were mi...

Embodiment 2

[0064] (1) Preparation of permeable brick aggregate

[0065] After crushing and sieving the first red mud melting slag, the permeable brick aggregate with a particle size of 4-5mm is obtained.

[0066] (2) Prepare the gelling material

[0067] uniformly mixing the crushed, sieved and ground second red mud slag, ground calcined kaolin and ground blast furnace slag according to the mass ratio of 1:0.5:0.2 to obtain mixed powder;

[0068] The particle size of the second red mud slag after grinding is 25-38 μm; the particle size of the calcined kaolin after grinding is 25-38 μm, and the particle size of the blast furnace slag after grinding is 25-38 μm. The activator is industrial grade water glass, where Na 2 The mass fraction of O is 8.75%, SiO 2 The mass fraction is 27.6%, and the modulus is 3.3. When in use, adjust the modulus of the water glass to 1.2 with NaOH.

[0069] (3) Preparation of geopolymer cementitious material

[0070] The mixed powder, the activator and wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com