Electrocatalytic oxidation electrode for sewage treatment and preparation method thereof

A technology for electrocatalytic oxidation and sewage treatment, which is applied in water/sewage treatment, oxidized water/sewage treatment, water/sludge/sewage treatment, etc. Oxidation and other problems, to achieve good electrochemical properties, good electron transfer performance, highlight the effect of electrocatalytic oxidation activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

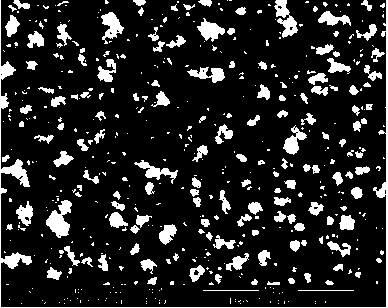

[0023] (1) Preparation of titanium-based boron-doped diamond film: ①Using a titanium plate with a thickness of 0.5mm as the substrate, soak it in dilute hydrochloric acid for 30 minutes to remove the oxide layer on the surface, then put it into alcohol for ultrasonic cleaning, and blow it dry with inert gas after taking it out; ②Use ultrasonic technology to inoculate diamond crystal seeds on the titanium plate, and the ultrasonic time is 5 minutes; the preparation method of diamond crystal seeds is: disperse powder diamond with a particle size of about 0.5 μm in acetone solution, and the mass ratio of powder diamond to acetone solution is 1:200; ③ Put the titanium plate prepared in ② into the reaction chamber of the microwave plasma vapor-phase chemical deposition equipment, use a vacuum pump to remove the air in the reaction chamber, and then pass CH 4 and H 2 As a reactive gas, mixed with H 2 The borane in is used as a boron dopant, and the reaction pressure is controlled t...

Embodiment 2

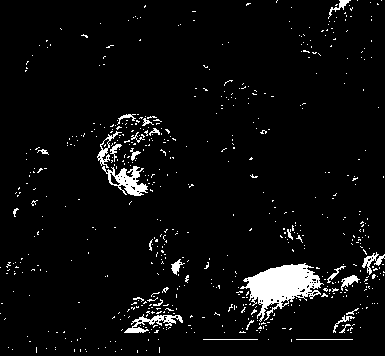

[0028] (1) Preparation of titanium-based boron-doped diamond film: ① Use a titanium mesh with a thickness of 2 mm as the substrate, soak it in 5% sodium hydroxide for 10 minutes to remove the oxide layer on the surface, then put it into alcohol for ultrasonic cleaning, and use an inert gas after taking it out Blow dry; ② use ultrasonic technology to inoculate diamond crystal seeds on titanium mesh, and the ultrasonic time is 20 minutes; the preparation method of diamond crystal seeds is: disperse powder diamond with a particle size of about 5 μm in acetone solution, and the mass ratio of powder diamond to acetone solution 1:40; ③ Put the titanium plate prepared in ② into the reaction chamber of the hot wire vapor chemical deposition equipment, use the vacuum pump to remove the air in the reaction chamber, and then pass CH 4 and H 2 As a reactive gas, mixed with H 2 The borane in is used as a boron dopant, and the reaction pressure is controlled to be 5000Pa, wherein CH 4 wit...

Embodiment 3

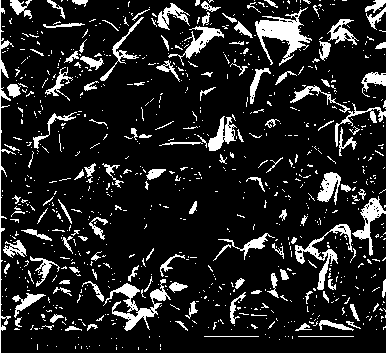

[0033] (1) Preparation of titanium-based boron-doped diamond film: ① Use a titanium plate with a thickness of 1 mm as the substrate, soak it in dilute sulfuric acid for 15 minutes to remove the oxide layer on the surface, then put it in alcohol for ultrasonic cleaning, and blow it dry with inert gas after taking it out; ② Ultrasonic technology is used to inoculate diamond crystal seeds on a titanium plate, and the ultrasonic time is 30min; the preparation method of diamond crystal seeds is: disperse powder diamond with a particle diameter of about 10 μm in acetone solution, and the mass ratio of powder diamond to acetone solution is 1: 20; ③ Put the titanium plate prepared in ② into the reaction chamber of the microwave plasma vapor-phase chemical deposition equipment, use a vacuum pump to remove the air in the reaction chamber, and then pass CH 4 and H 2 As a reactive gas, mixed with H 2 The borane in is used as a boron dopant, and the reaction pressure is controlled to be 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com