High-performance quantum dot white light LED and preparing method thereof

A quantum dot, high-performance technology, applied in the field of high-performance quantum dot white light LED and its preparation, can solve the problems of low luminous efficiency and low luminous stability, and achieve the effects of high luminous efficiency, good color rendering and obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

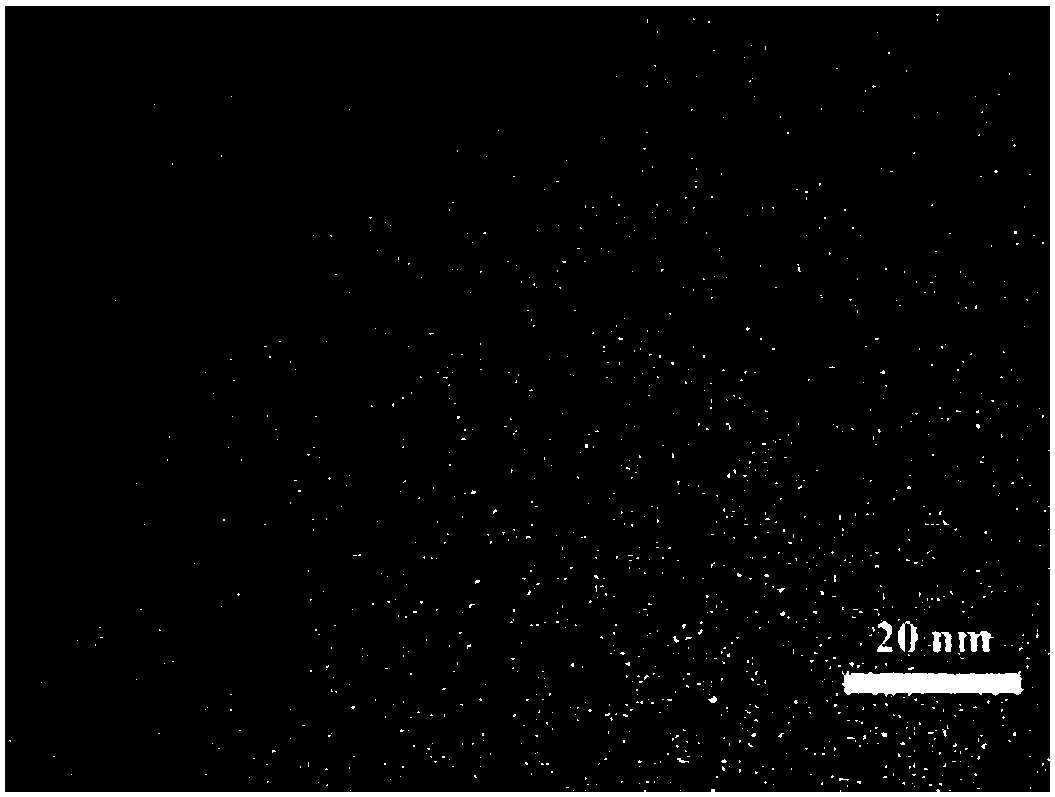

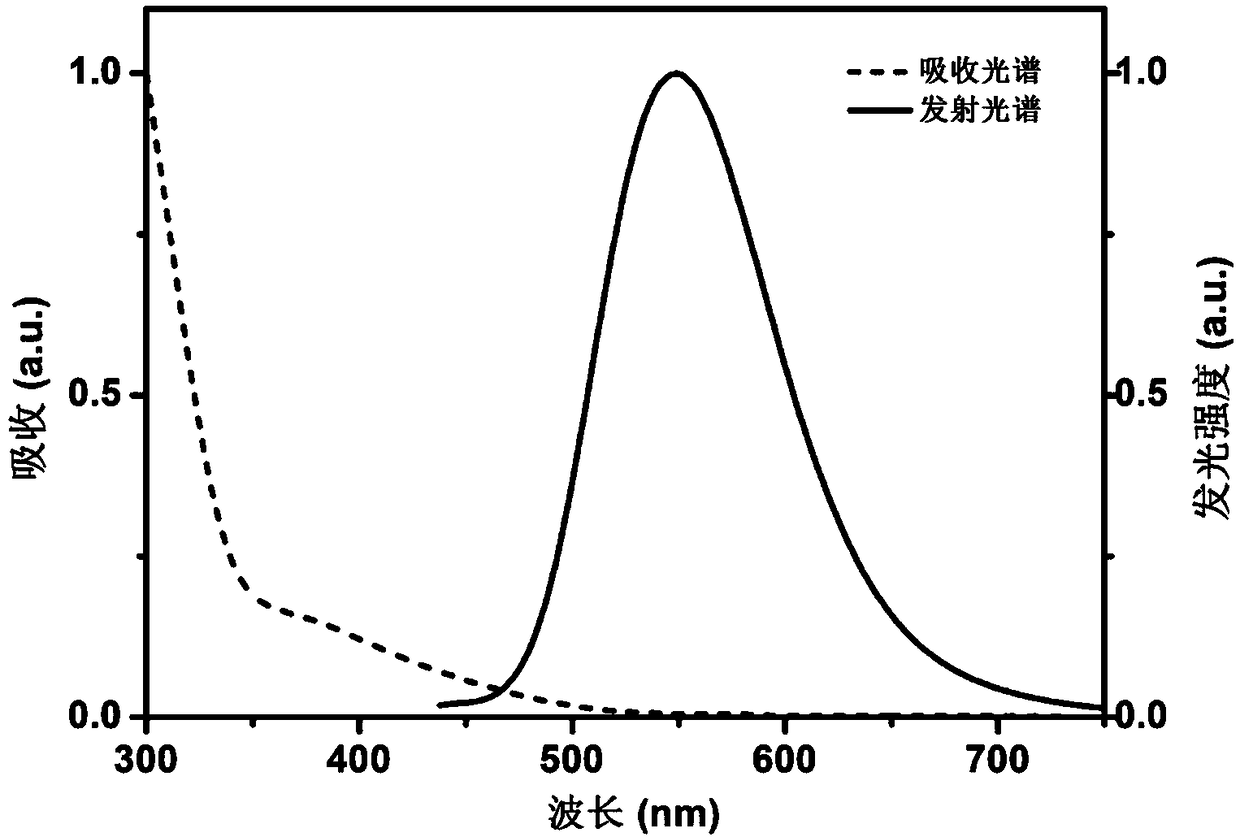

[0035] Weigh 0.073g (0.4mmol) zinc acetate (Zn(OAc) 2 ), 0.008g (0.04mmol) copper acetate (Cu(OAc) 2 ), 0.117g (0.4mmol) indium acetate (In(OAc) 3 ), 0.102g (3.2mmol) of sulfur powder (S), measure 8.0mL of dodecanethiol (DDT), and 12.0mL of oleylamine (OAm) into a 50mL three-necked flask. The high-purity nitrogen atmosphere in the bottle is guaranteed by repeated vacuuming and nitrogen ventilation. Then, the mixed solution was heated from room temperature to 220° C. at a heating rate of 15° C. / min and kept for 10 min to grow Cu:ZnInS nuclei. Subsequently, the temperature was lowered to 100°C, and the zinc precursor solution (0.146g Zn(OAc) 2 Dissolved in 1.6mL ODE and 0.4mL OAm) and maintained for 20min, followed by injection of aluminum precursor (4mmol (0.816g) aluminum isopropoxide (Al(IPA) 3 ) was dissolved in 2mL DDT). Finally, the mixed solution was heated from room temperature to 240 °C at a heating rate of 15 °C / min and kept for 10 h. Add 5mL methanol and 5mL chl...

Embodiment 2

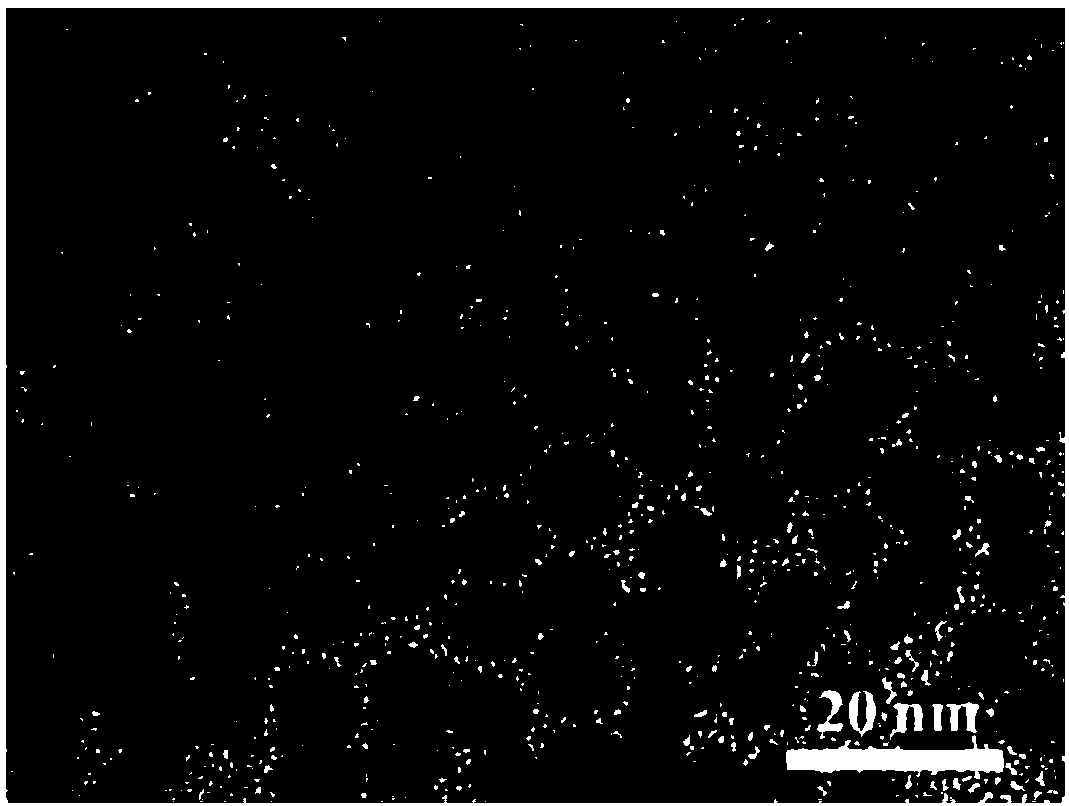

[0038] Weigh 0.128g (1mmol) cadmium oxide (CdO), 0.267g (2mmol) Zn (OAc) 2 , Measure 5mL of OA, and 25mL of octadecene (ODE) into a 50mL three-necked flask. The high-purity nitrogen atmosphere in the bottle was ensured by repeated vacuuming and nitrogen ventilation, and the mixed solution was heated from room temperature to 300 °C at a heating rate of 15 °C / min, and the selenium precursor solution (0.016g (0.2 mmol) selenium powder (Se) was dissolved in 0.2 mL trioctylphosphine (TOP) solution). After the reaction was carried out for 2.5 min, 0.3 mL of DDT was slowly injected into the reaction solution, and kept at 300° C. for 20 min to grow CdSe / CdZnS quantum dots. Finally, the S precursor solution (2mmol S dissolved in 1mL TOP) was injected into the mixed solution and kept for 10min to grow the ZnS shell to obtain CdSe / CdS / ZnS quantum dots. Add 5mL of methanol and 5mL of acetone to the obtained quantum dot solution, precipitate under the action of a centrifuge at 5000rpm, a...

Embodiment 3

[0041] Get 2mL (100mg / mL) Cu in embodiment 1:ZnInS / ZnS / ZnS:Al quantum dot solution and 1mL (0.8mg / mL) CdSe / CdS / ZnS quantum dot solution in embodiment 2 join in filling 1.2g silica gel Put resin A in a glass bottle, stir evenly, place in a vacuum oven at 50°C, and heat-treat for 30 minutes to remove the solvent. Subsequently, 0.6 g of silicone resin B curing agent was added to the solution and stirred evenly. Finally, 20 μL of the obtained quantum dot / silicone resin mixture was drop-coated on the ultrasonically cleaned silicon wafer, cured in air at room temperature for 2 h, and then dried in a vacuum oven at 80 ° C for 2 h. The obtained device was designated as sample A (green + red), the thickness of the quantum dot film is about 20 μm, and its luminous decay curve is measured. The obtained curve is as Figure 5 As shown in the middle green + red (open square), the luminous lifetime is summarized in Table 1. From the table, it is found that the lifetime of Cu:ZnInS / ZnS / ZnS:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com