Heating and heat-insulating type oil conveying pipeline assembly

An oil pipeline, heating and thermal insulation technology, applied in the direction of thermal insulation protection pipeline, thermal insulation, pipeline protection, etc., can solve the problems of poor flow, pressure loss, excessive oil viscosity, etc., to ensure smooth flow and prevent the spread of temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

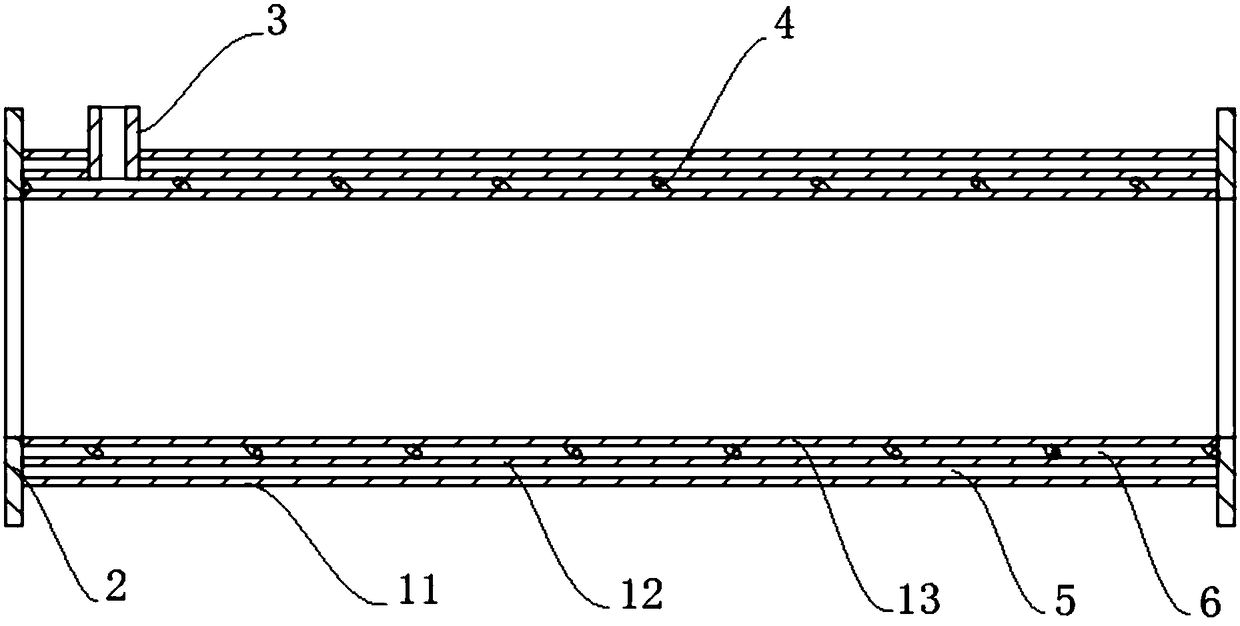

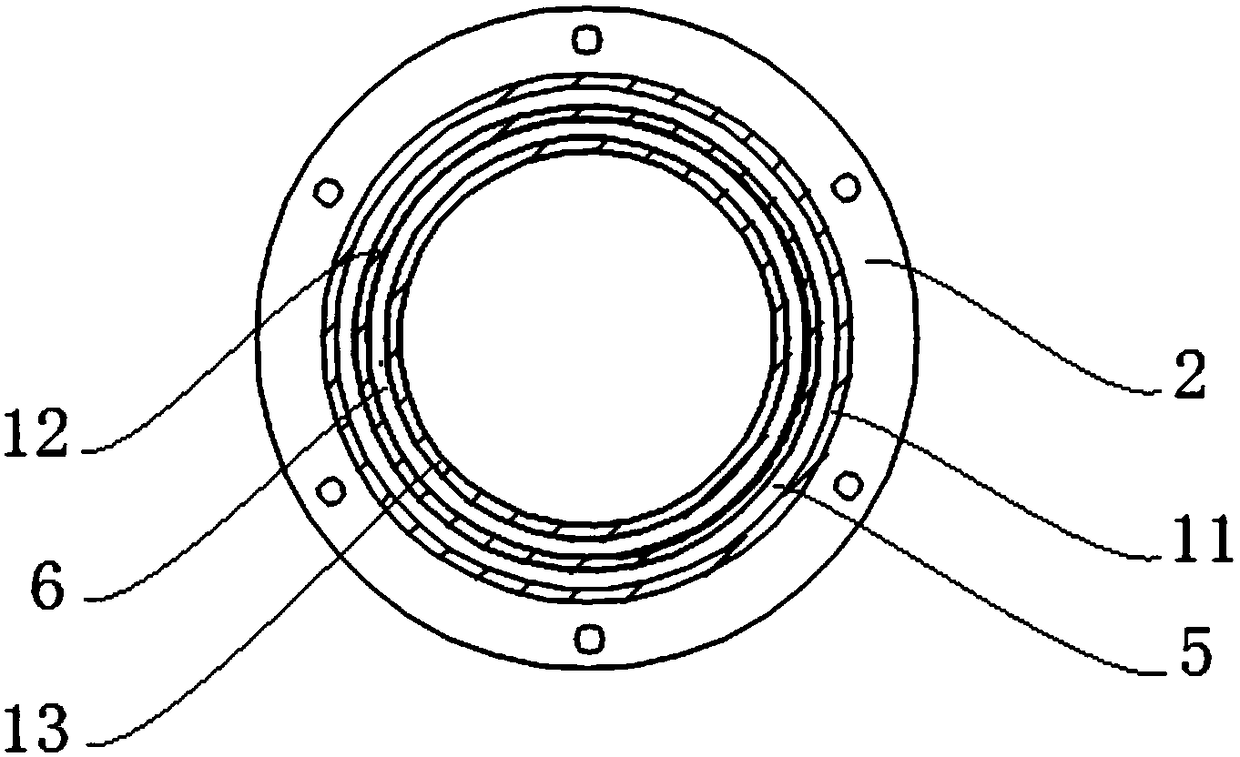

[0021] Such as Figure 1 to Figure 3 As shown, a heating and heat preservation type oil pipeline assembly of the present invention includes a flange 2 and an oil pipeline 1, the oil pipeline 1 is fixed and sealed with the flange 2, the flange 2 is provided with a mounting hole, and the flange 2 is provided with 2 groups, and the flanges 2 are sealed and fixed at both ends of the oil pipeline 1 respectively. The oil pipeline 1 is provided with a pipeline outer layer 11, a pipeline middle layer 12 and a pipeline inner layer 13, and the inner wall of the pipeline inner layer 13 and the outer wall of the pipeline outer layer 11 are coated with anti-corrosion paint; the pipeline outer layer 11 and the pipeline middle layer 12 is provided with a vacuum chamber 5, the middle layer of the pipeline 12 and the inner layer of the pipeline 13 are provided with a heating chamber 6, and the heating chamber 6 is provided with a heating tube 4, the heating tube 4 is an electric heating wire, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com