Heat treatment method of high-strength bolt for electric tool

A technology of high-strength bolts and heat treatment methods, applied in heat treatment furnaces, heat treatment equipment, manufacturing tools, etc., can solve problems such as the inability to meet the requirements of high-power, lightweight electric tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

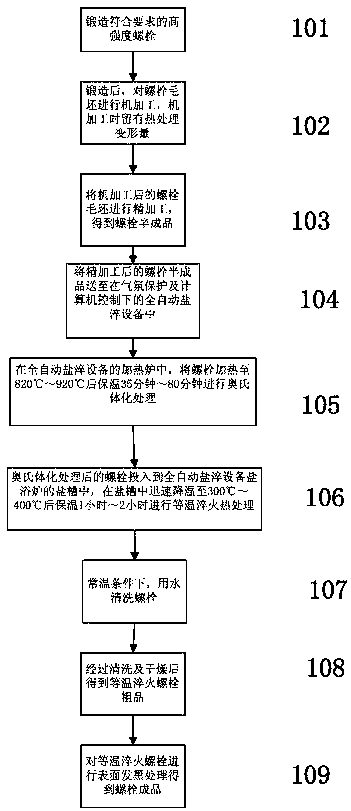

Method used

Image

Examples

Embodiment 1

[0047] A heat treatment method for high-strength bolts used in impact electric drills, using standard M10x35 / 12.9 bolts made of 42CrMo, therefore, the process before the bolt isothermal quenching heat treatment is omitted, mainly including the following steps:

[0048] (1) Send the bolt workpiece to the fully automatic salt quenching equipment under atmosphere protection and computer control, and the protection atmosphere is carbon monoxide;

[0049] (2) In the heating furnace of the fully automatic salt quenching equipment, the bolts are heated to 900°C and then held for 80 minutes for austenitization;

[0050] (3) Put the bolts that have been austenitized in step (2) into the salt tank of the salt bath furnace of the automatic salt quenching equipment, rapidly cool down to 370°C in the salt tank, and then keep it warm for 1.5 hours for austempering heat treatment; Wherein, the molten salt solution is a mixed solution of potassium nitrate with a mass ratio of 50% and sodium n...

Embodiment 2

[0056] A heat treatment method for high-strength bolts for electric hammers, using standard bolts of M10x35 / 12.9 grade, omitting forging and other general procedures, mainly including the following steps:

[0057] (1) Send the bolts to the fully automatic salt quenching equipment under atmosphere protection and computer control, and the protection atmosphere is carbon monoxide;

[0058] (2) In the heating furnace of the fully automatic salt quenching equipment, the bolts are heated to 820°C and then held for 40 minutes for austenitization;

[0059] (3) Put the bolts treated with austenite in step (2) into the salt tank of the salt bath furnace of the automatic salt quenching equipment, rapidly cool down to 330° C. in the salt tank, and then keep warm for 1 hour to carry out austempering heat treatment; , the molten salt solution is a mixed solution of potassium nitrate with a mass ratio of 50% and sodium nitrate with a mass ratio of 50%;

[0060] (4) Under normal temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com