Environment-friendly PVC plastic dipping liquid

A technology of dipping liquid and PVC resin powder, which is applied in the field of polyvinyl chloride environmental protection materials, can solve the problems of increasing equipment investment, handling difficulties, burning motors, etc., and achieves the effect of low manufacturing cost, good economy and uniform coloring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

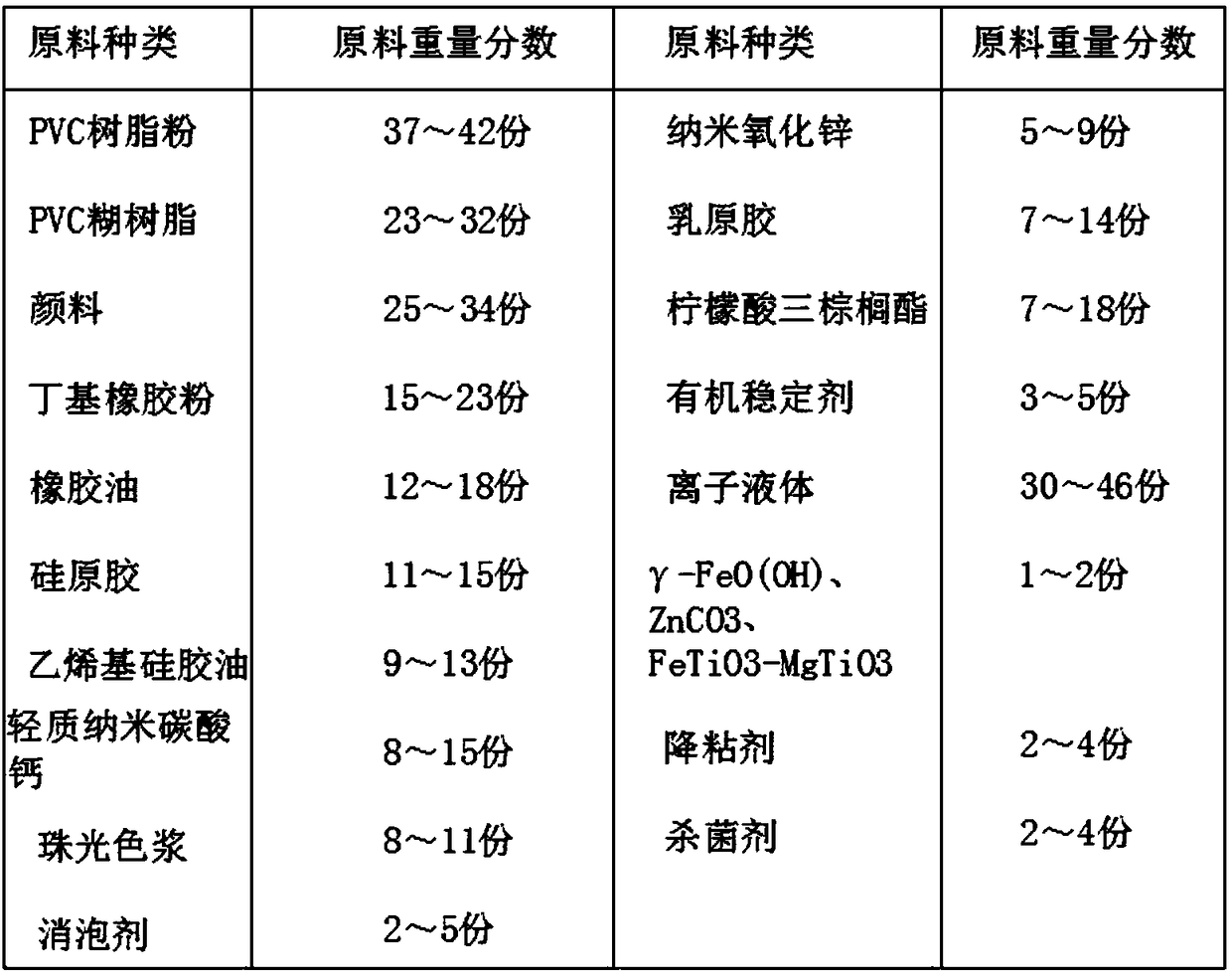

[0022] see figure 1 As shown, the technical solution adopted in the present invention is: an environment-friendly PVC dipping solution, which includes the following raw materials: 42 parts of PVC resin powder, 23 parts of PVC paste resin, 34 parts of pigment, butyl rubber 15 parts of powder, 18 parts of rubber oil, 11 parts of silicone gum, 13 parts of vinyl silicone oil, 8 parts of light nano-calcium carbonate, 9 parts of nano-zinc oxide, 7 parts of latex gum, 18 parts of tripalmityl citrate, 3 parts of organic stabilizer and 46 parts of ionic liquid.

[0023] Wherein, 1 part of γ-FeO(OH), ZnCO 3 and FeTiO 3 -MgTiO 3 A mixture of, among them, γ-FeO(OH), ZnCO 3 and FeTiO 3 -MgTiO 3 The addition ratio is 3:2:1.

[0024] Wherein, 2 parts of viscosity reducer are added to the environment-friendly PVC dipping solution, wherein the viscosity reducer is dearomatized hydrocarbon viscosity reducer.

[0025] Wherein, 11 parts of pearlescent color paste are added to the environm...

Embodiment 2

[0031] see figure 1 As shown, the technical solution adopted in the present invention is: an environmentally friendly PVC dipping solution, which includes the following raw materials: 37 parts of PVC resin powder, 32 parts of PVC paste resin, 25 parts of pigment, butyl rubber 23 parts of powder, 12 parts of rubber oil, 15 parts of silicone gum, 9 parts of vinyl silicone oil, 15 parts of light nano-calcium carbonate, 5 parts of nano-zinc oxide, 14 parts of latex gum, 7 parts of tripalmityl citrate, 5 parts of organic stabilizer and 30 parts of ionic liquid.

[0032] Wherein, 2 parts of γ-FeO(OH), ZnCO 3 and FeTiO 3 -MgTiO 3 A mixture of, among them, γ-FeO(OH), ZnCO 3 and FeTiO 3 -MgTiO 3 The addition ratio is 2:2:1.

[0033] Wherein, 4 parts of a viscosity reducer are added to the environment-friendly PVC dipping solution, wherein the viscosity reducer is a dearomatized hydrocarbon viscosity reducer.

[0034] Wherein, 8 parts of pearlescent color paste are added to the ...

Embodiment 3

[0040] see figure 1 As shown, the technical solution adopted in the present invention is: an environmentally friendly PVC dipping solution, which includes the following raw materials: 42 parts of PVC resin powder, 32 parts of PVC paste resin, 34 parts of pigment, butyl rubber 23 parts of powder, 18 parts of rubber oil, 5 parts of silicone gum, 13 parts of vinyl silicone oil, 15 parts of light nano-calcium carbonate, 9 parts of nano-zinc oxide, 14 parts of latex gum, 18 parts of tripalmityl citrate, 5 parts of organic stabilizer and 46 parts of ionic liquid.

[0041] Wherein, 2 parts of γ-FeO(OH), ZnCO 3 and FeTiO 3 -MgTiO 3 A mixture of, among them, γ-FeO(OH), ZnCO 3 and FeTiO 3 -MgTiO 3 The addition ratio is 3:2:3.

[0042]Wherein, 4 parts of a viscosity reducer are added to the environment-friendly PVC dipping solution, wherein the viscosity reducer is a dearomatized hydrocarbon viscosity reducer.

[0043] Wherein, 11 parts of pearlescent color paste are added to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com