A kind of photoreversible crosslinking organosilicon resin and preparation method thereof

A technology of cross-linking silicone and silicone, which is applied in the field of photoreversible cross-linking silicone resin and its preparation, can solve the problems of difficult natural decomposition and failure of resource recycling of silicone resin, and achieve excellent processing suitability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

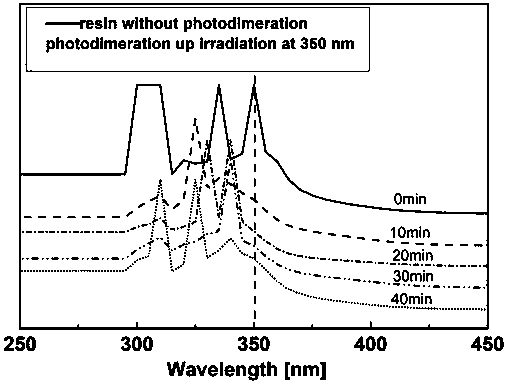

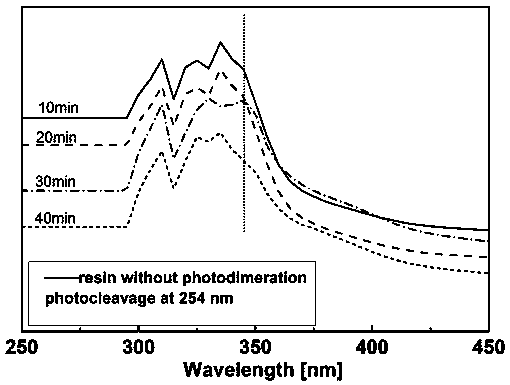

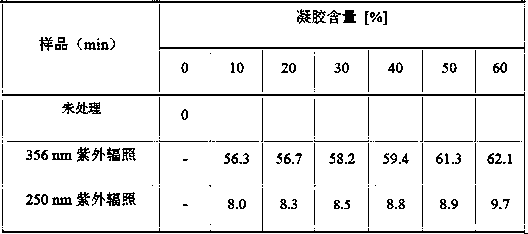

[0021] Mix amino-terminated silicone oil and cinnamoyl chloride at a mass ratio of 100:20, dissolve in γ-aminopropyltriethoxysilane (3wt% of the mass of the mixture), add 5wt‰ of 4-dimethylaminopyridine as a catalyst , react at 30°C for 24h, and then add excess acetone to precipitate a photoreversible cross-linked silicone resin. The photoreversible cross-linking silicone resin film is molded at 80°C by a flat vulcanizing machine, and realizes photo-induced cross-linking under 356nm ultraviolet light irradiation and photo-induced decomposition under 250nm ultraviolet light irradiation. crosslinking.

Embodiment 2

[0023] Mix epoxy-terminated silicone oil and 6,7-dihydroxycoumarin at a mass ratio of 100:30, dissolve in γ-(2,3-epoxypropoxy)propyltrimethoxysilane (the amount is 1% of the mass of the mixture) 5wt%), adding 10wt‰ of boron trifluoride as a catalyst, and performing a ring-opening reaction at 150°C for 24 hours to obtain a photoreversible cross-linked silicone resin. The photoreversible crosslinking silicone resin can be molded by stereolithography (SLA) process technology at 80°C, and realizes photocrosslinking under 356nm ultraviolet light irradiation and photodecrosslinking under 250nm ultraviolet light irradiation. couplet.

Embodiment 3

[0025] Dissolve epoxy-terminated silicone oil and 7-amino-4-methylcoumarin in γ-(2,3-epoxypropoxy)propyltrimethoxysilane with a mass ratio of 100 / 40 (the amount is 1% of the mixture mass 3wt%), add 5wt‰ of sodium ethylate as a catalyst, and react at 80°C for 12h to obtain a photoreversible cross-linked silicone resin. The photoreversible cross-linking silicone resin can be formed by stereolithography (SLA) process technology at 90°C, and realizes photo-crosslinking under 356nm ultraviolet light irradiation and photo-decrosslinking under 250nm ultraviolet light irradiation. couplet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com