Preparation method of three-dimensional porous graphene material

A three-dimensional porous and graphene technology, applied in graphene, chemical instruments and methods, inorganic chemistry, etc., can solve problems that do not conform to the development direction of modern green chemical industry, and achieve the effect of excellent electrochemical energy storage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

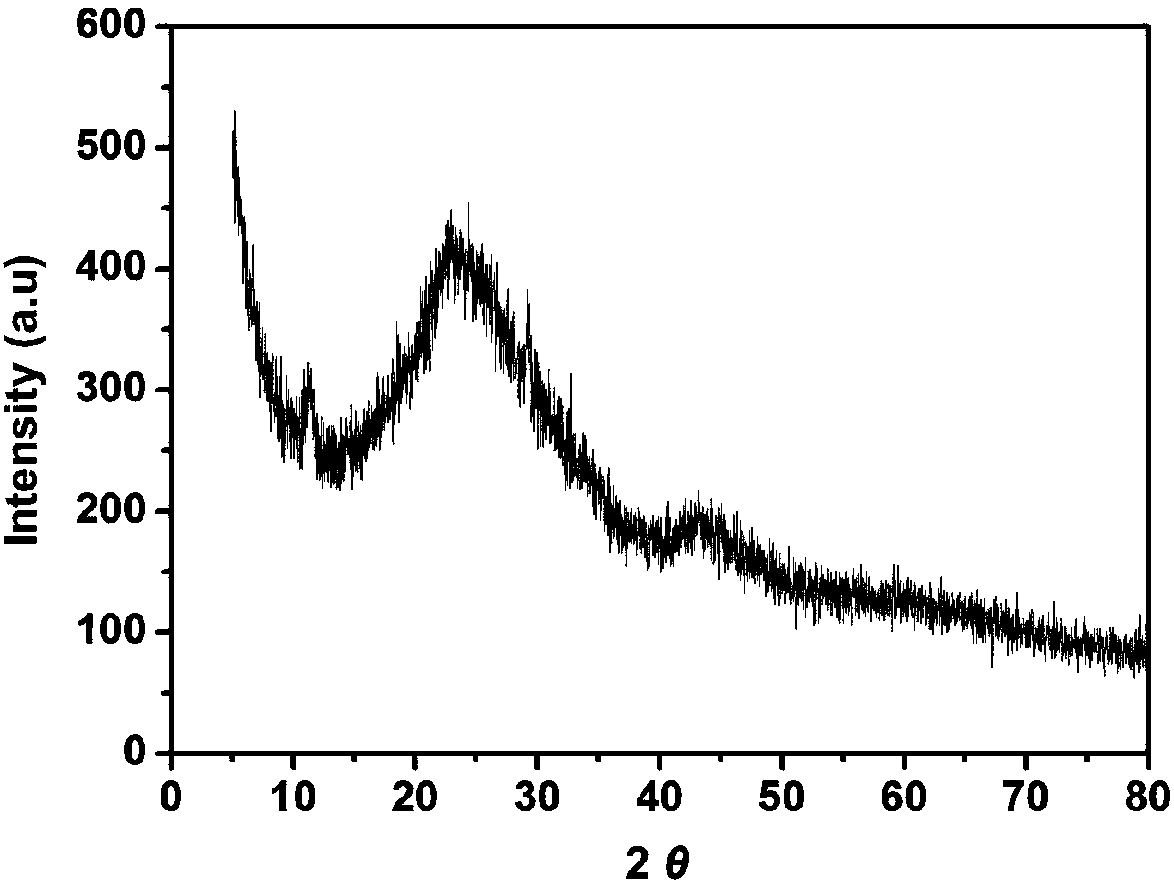

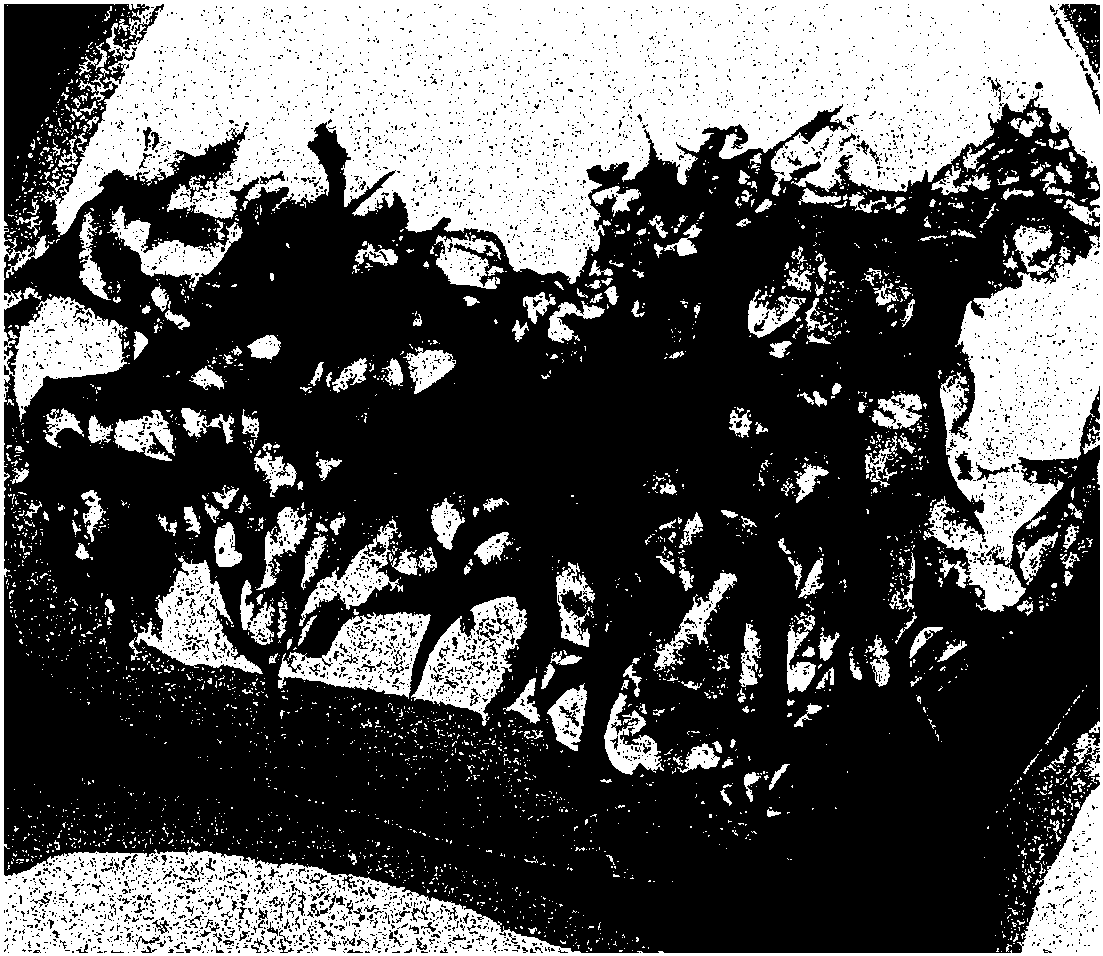

Embodiment 1

[0022] Take 10 grams (g) of polycarbonate, 10 g of sodium bicarbonate and 8 milliliters (ml) of deionized water and stir together to form a homogeneous mixture. Then transfer the uniformly mixed material into a PTFE reactor (with a stainless steel jacket outside), put the reactor into an oven, heat up to 160 ° C, and then keep the temperature for 5 hours (h), after cooling to room temperature with the furnace temperature, put It was taken out and dried in an oven, then put into a porcelain crucible and heated up to 700°C at a rate of 5°C per minute (°C / min) in a vacuum atmosphere furnace, kept at a constant temperature for 5 hours, cooled naturally with the furnace temperature, and then taken out. The reaction product was washed with deionized water until the pH value of the filtrate was 7, and then dried in a vacuum oven at 65 degrees Celsius (°C) for 12 hours to obtain a specific surface area of 1150 m 2 / g of 3D porous graphene-like materials. The prepared material is us...

Embodiment 2

[0024] Take 15 g of polyethylene terephthalate (PET) and 5 g of polyethylene with 15 g of sodium carbonate and 10 ml of deionized water, and stir together to form a homogeneous mixture. Then transfer the homogeneously mixed material into a PTFE reactor (with a stainless steel jacket outside), put the reactor into an oven, raise the temperature to 180°C, and then keep the temperature for 4 hours. After cooling to room temperature with the furnace temperature, take it out in the oven. dried in an oven, and then placed in a porcelain crucible under nitrogen (N 2 ) in a protective atmosphere furnace, raise the temperature to 800°C at a rate of 6°C / min, keep the temperature constant for 3 hours, and take it out after cooling naturally with the furnace temperature. The reaction product was washed with deionized water until the pH value of the filtrate was 7, and then dried in a freeze-drying device at -40 °C for 12 h to obtain a specific surface area of 1100 m 2 / g of 3D porous g...

Embodiment 3

[0026] Take 15 g of polymethyl methacrylate (PMMA) and 10 g of potassium carbonate mixed with 10 g of potassium bicarbonate powder and 10 ml of deionized water, and stir together to form a homogeneous mixture. Then transfer the homogeneously mixed material into a PTFE reactor (with a stainless steel jacket outside), put the reactor into an oven, heat up to 200°C, and then keep the temperature for 3 hours. After cooling to room temperature with the furnace temperature, take it out in the oven. Dry it in an oven, then put it into a porcelain crucible in an argon (Ar) protective atmosphere furnace, raise the temperature to 850°C at a rate of 6°C / min, keep the temperature constant for 2h, and take it out after cooling naturally with the furnace temperature. The reaction product was washed with deionized water until the pH value of the filtrate was 7, and then dried in a vacuum oven at 80 °C for 10 h to obtain a specific surface area of 1050 m 2 / g of 3D porous graphene-like mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com