Novel combined trimming machine tool

A combined and new type of technology, applied in driving devices, metal processing machinery parts, turning equipment, etc., can solve problems such as parts damage, falling off, and the motor not being able to stop immediately.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

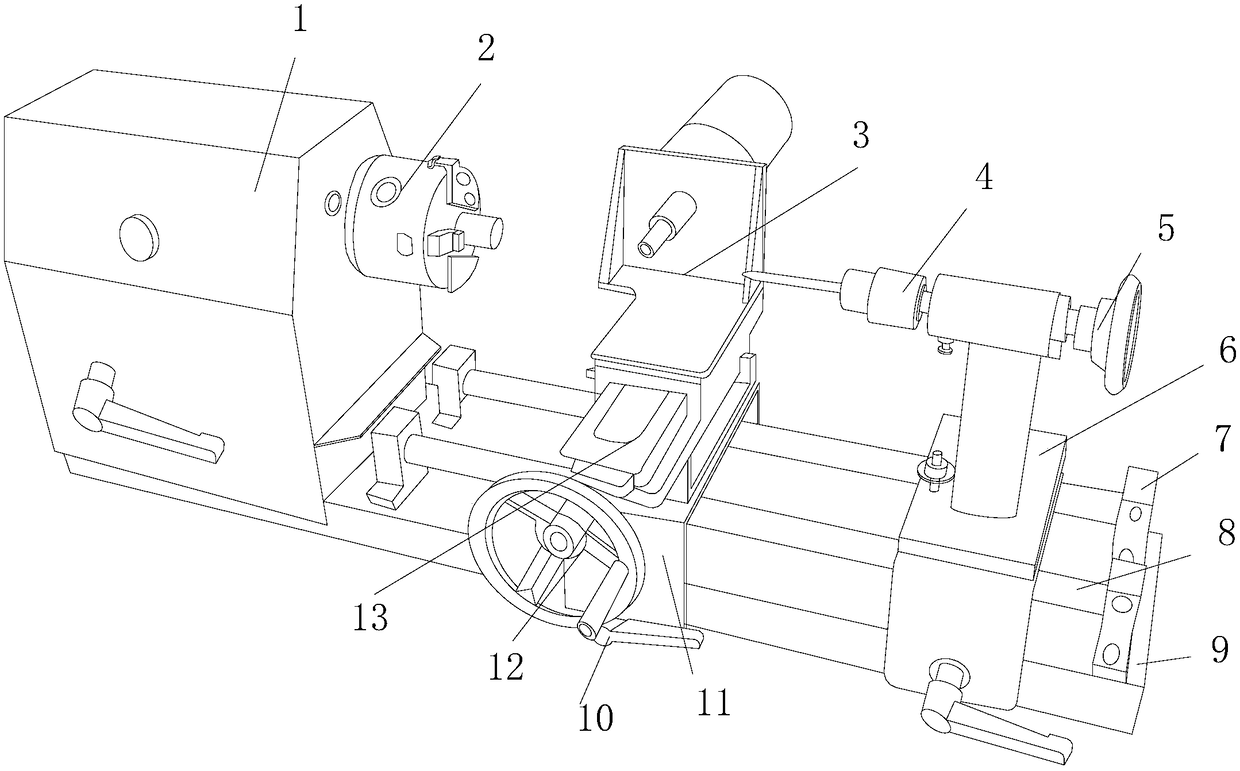

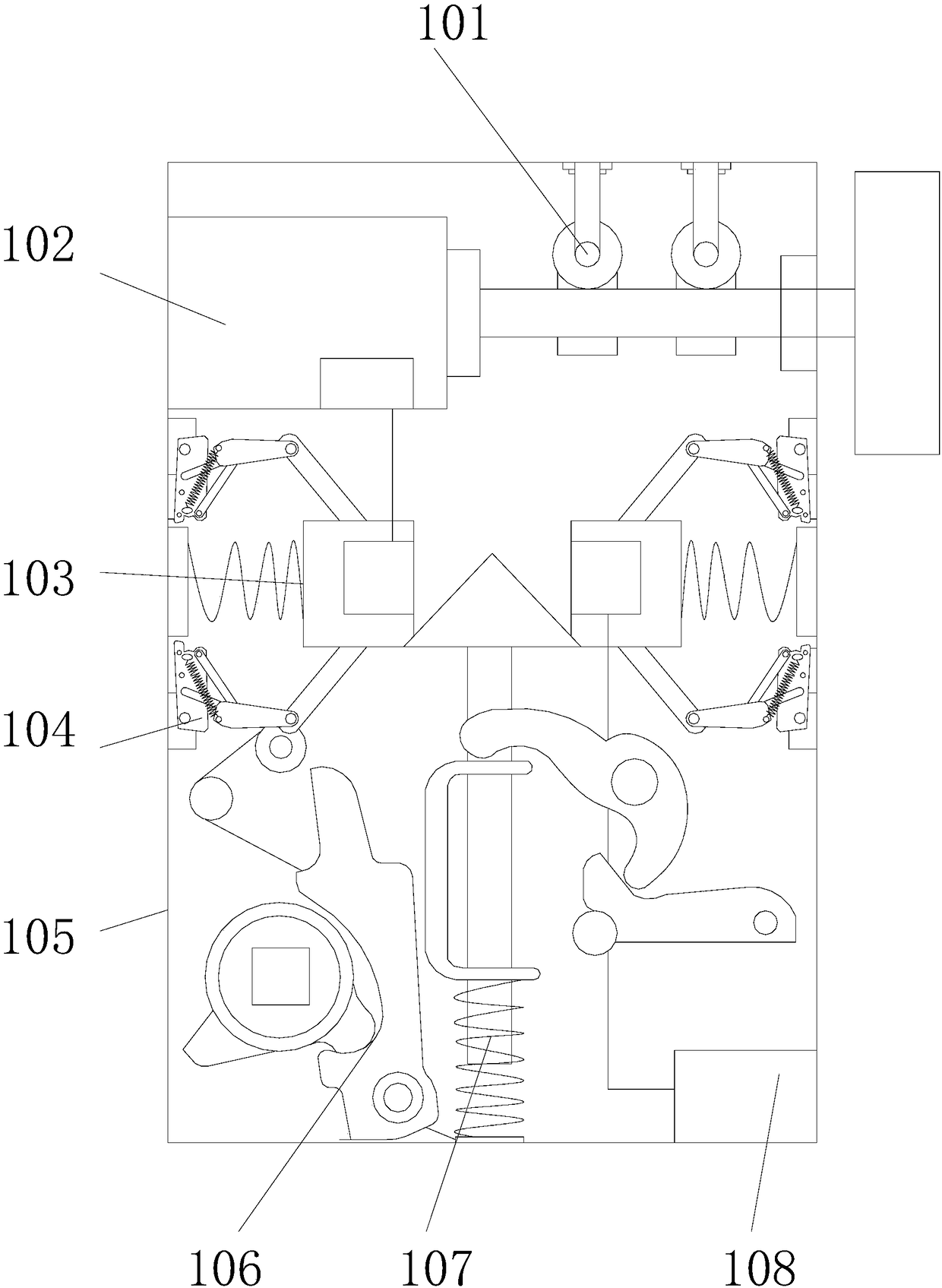

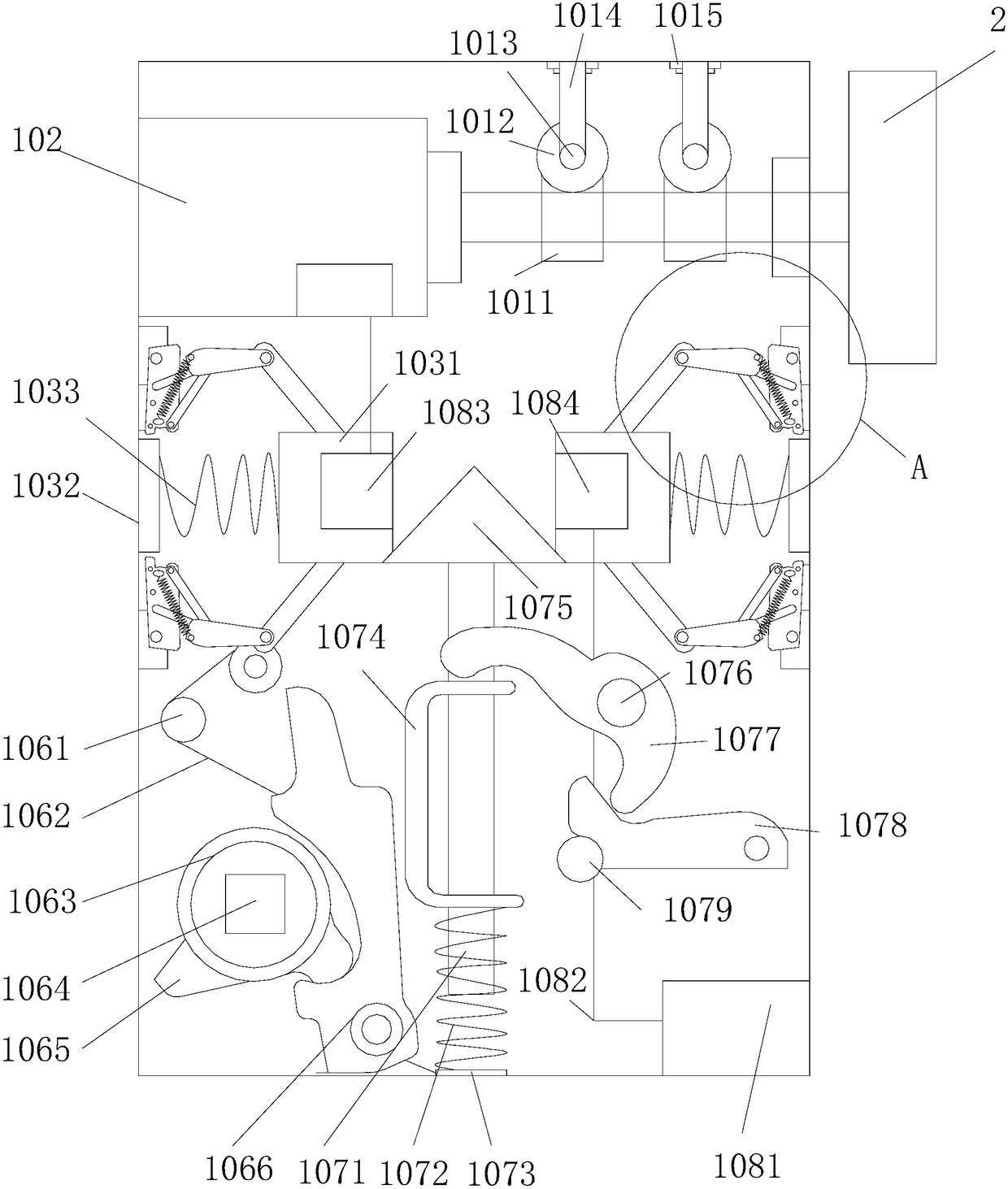

[0023] see Figure 1-Figure 4 , the present invention provides a new type combined decoration machine tool, its structure includes emergency stop system 1, main shaft 2, fixed seat 3, tool rest 4, speed change hand wheel 5, tailstock 6, screw screw fixing seat 7, screw mandrel 8 , lathe 9, handwheel 10, slide crate 11, second handwheel 12, small slide plate 13, described emergency stop system 1 and main shaft 2 mechanical connections, described emergency stop system 1 is installed on lathe 9 one ends, The other end of the lathe 9 is equipped with a tailstock 6, the tailstock 6 is vertically fixed with a knife rest 4, the knife rest 4 is mechanically connected with the speed change handwheel 5, and the lathe 9 is provided with two Screw rods 8 parallel to each other, the two ends of the screw rod 8 are fixed on the upper surface of the lathe 9 through the screw holder 7, the tailstock 6 and the screw rod 8 are slidingly fitted, and the tailstock 6 and the main shaft 2 is insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com