Supersonic flame spraying spray pipe

A supersonic flame and nozzle technology, which is applied in coating, melt spraying, metal material coating process, etc., can solve the problems of increased fuel cost, scratched nozzle, short service life, etc., to reduce spraying power, The effect of increasing the service life and widening the range of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below by embodiment the content of the present invention is specified:

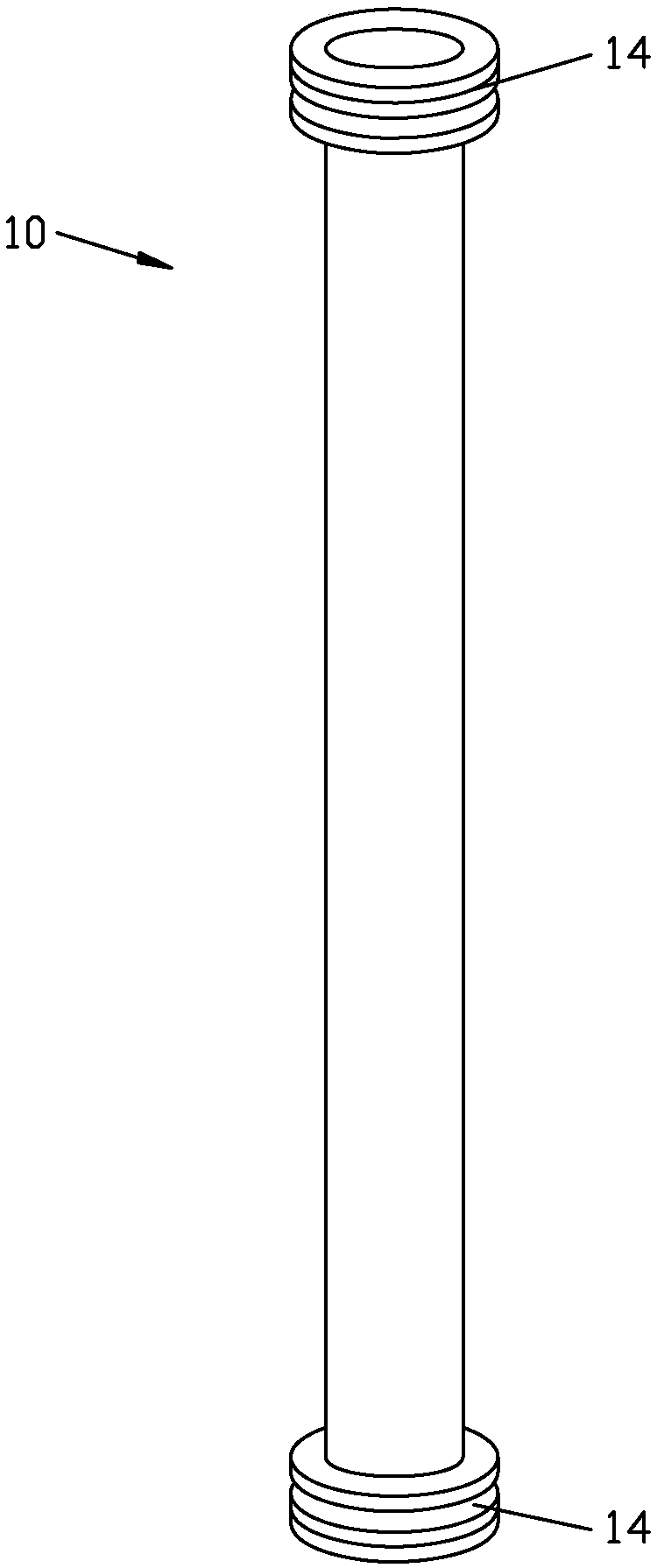

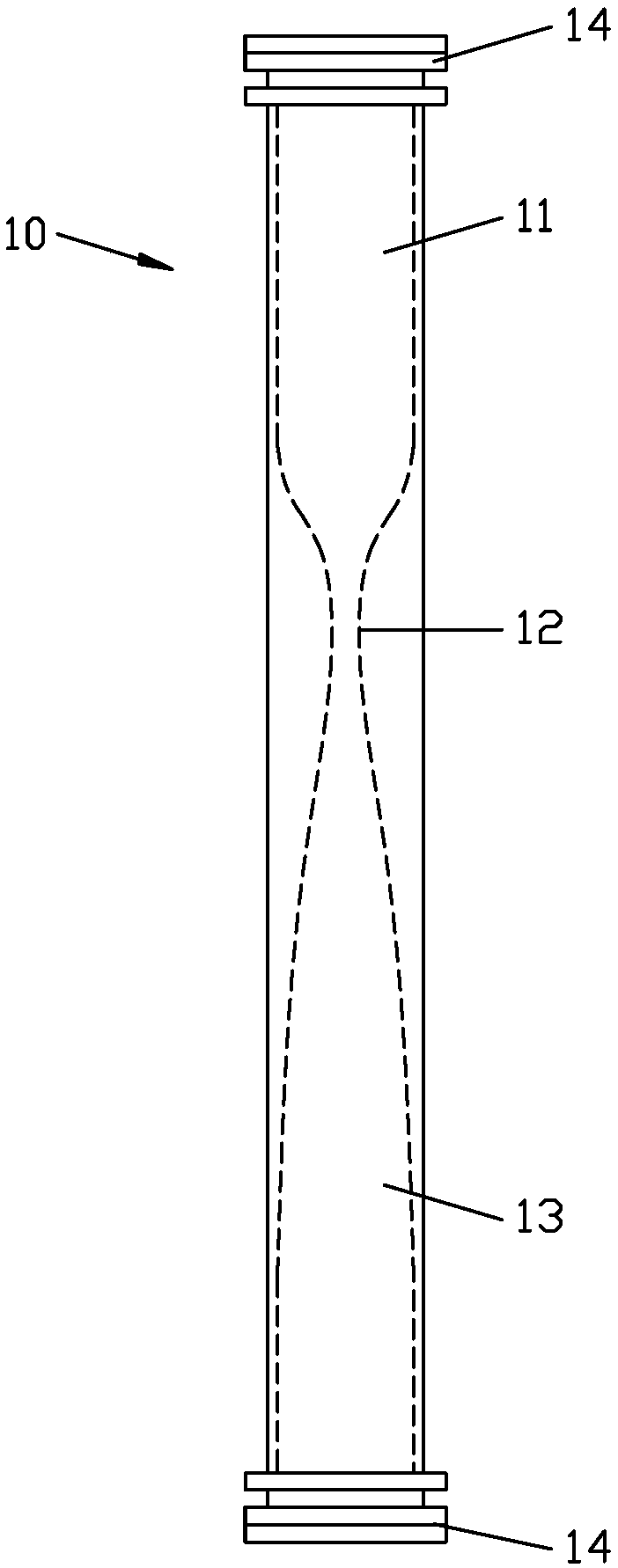

[0029] Please check figure 1 , is the supersonic flame spraying nozzle 10 of the present invention, the nozzle 10 is made of a molybdenum alloy material, and the molybdenum alloy material includes: chromium 2-3wt%, nickel 8-9wt%, carbon 0-0.15 wt%, iron 0~2.5wt%, manganese 0.4~0.9wt%, silicon 0.6~1wt%, boron 0~0.01wt%, phosphorus 0~0.02wt%, sulfur 0~0.02wt%, the rest is molybdenum, it is also possible Trace amounts of unavoidable impurities are present.

[0030] Wherein, the chromium content is for example 2wt%, 2.5wt%, 3wt%; the nickel content is for example 8wt%, 8.5wt%, 9wt%; wt%; iron content such as 0wt%, 0.5wt%, 1wt%, 1.5wt%, 2wt%, 2.5wt%; manganese content such as 0.4wt%, 0.5wt%, 0.6wt%, 0.7wt%, 0.8wt% %, 0.9wt%; silicon content such as 0.6wt%, 0.7wt%, 0.8wt%, 0.9wt%, 1.0wt%; boron content such as 0wt%, 0.002wt%, 0.005wt%, 0.008wt%, 0.01 wt%; phosphorus content such as 0wt%, 0.005wt%, 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com