Crosslinker for recoverable polymer fracturing fluid, and preparation method and application thereof

A technology of cross-linking agent and fracturing fluid, which is applied in the field of fracturing fluid, can solve the problems that restrict the development of seepage oil and gas fields, and cannot be effectively treated and utilized, and achieve the effects of shortening the water preparation cycle, solving difficult treatment, and saving fresh water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

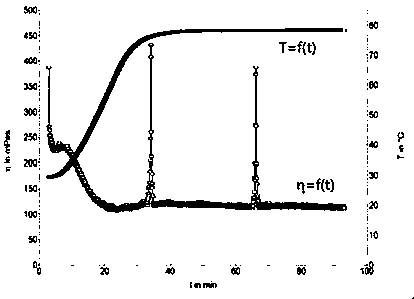

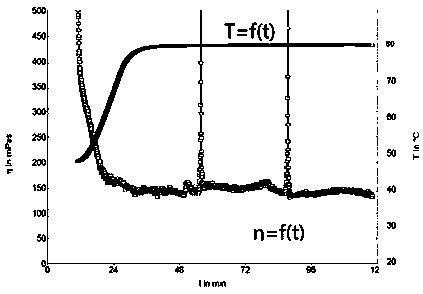

Image

Examples

Embodiment 1

[0028] This embodiment provides a recyclable polymer cross-linking agent for fracturing fluid. The cross-linking agent can be re-cross-linked with the gel breaking fluid through a complexation reaction to form a fracturing fluid.

[0029] The crosslinking agent includes the following components: by mass percentage, 3%-8% high-valent metal salt, 12%-18% polyol, 0.5%-2% regulator, 2%-6% surfactant, 1%-2% anticoagulant and 64%-81.5% distilled water.

[0030] The high-valent metal salt is one or more of zirconium oxychloride, polyaluminum chloride, and aluminum trichloride.

[0031] The polyhydroxy compound is one or more of glycerol, mannitol and ethylene glycol.

[0032] The regulator is one of formic acid, acetic acid and lactic acid.

[0033] The surfactant is C 16 -C 22 Long chain alkyl polyoxyethylene ether.

[0034] The anticoagulant is one or both of sodium citrate and potassium citrate.

[0035] The cross-linking agent for the recyclable polymer fracturing fluid pro...

Embodiment 2

[0037] This embodiment provides a method for preparing a cross-linking agent for recyclable polymer fracturing fluid, which is characterized in that it includes the following steps:

[0038] Step 1. Add 3%-8% high-valent metal salt to 64%-81.5% distilled water and stir until completely dissolved;

[0039] Step 2, add 12%-18% polyol, heat the system to 60°C, and react for 4 hours;

[0040] Step 3, then add 0.5%-2% regulator, 2%-6% surfactant, and 1%-2% anticoagulant in sequence;

[0041] Step 4: Stop heating and continue stirring for 0.5 hour to obtain a cross-linking agent for recyclable polymer fracturing fluid.

[0042] Further, the stirring rate in the step 1 is 100 rpm.

Embodiment 3

[0044] This embodiment provides an application method of a recyclable polymer fracturing fluid cross-linking agent, and the steps of using the cross-linking agent to prepare the fracturing fluid are as follows:

[0045] Step 1. Prepare the following components: by mass percentage, 0.35%-0.45% thickener, 0.3%-0.5% drainage aid, 0.3%-0.5% clay stabilizer, 0.004%-0.01% ammonium persulfate, 0.3 %-0.5% cross-linking agent, the balance is clear water or flowback fluid of polymer fracturing fluid;

[0046] Step 2. Add 0.35%-0.45% thickener to the flowback fluid of clean water or polymer fracturing fluid, stir evenly, then add 0.3%-0.5% clay stabilizer, 0.3%-0.5% drainage aid, 0.004% -0.01% ammonium persulfate, and finally add 0.3%-0.5% cross-linking agent to form fracturing fluid. The fracturing fluid is well cross-linked and can be completely suspended.

[0047] Preferably, the fracturing fluid is composed of the following mass percentages: 0.4% thickener, 0.3% drainage aid, 0.3% c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com