A kind of gypsum-based sandless mold machine-sprayed lightweight plastering material and preparation method thereof

A sand molding machine and gypsum-based technology, which is applied in the field of building materials, can solve the problems of reducing the conditions for later maintenance, can not be repaired repeatedly for a long time, and does not solve the problems of gypsum machine spraying, etc., and achieves the effects of reducing labor costs, saving self-weight, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

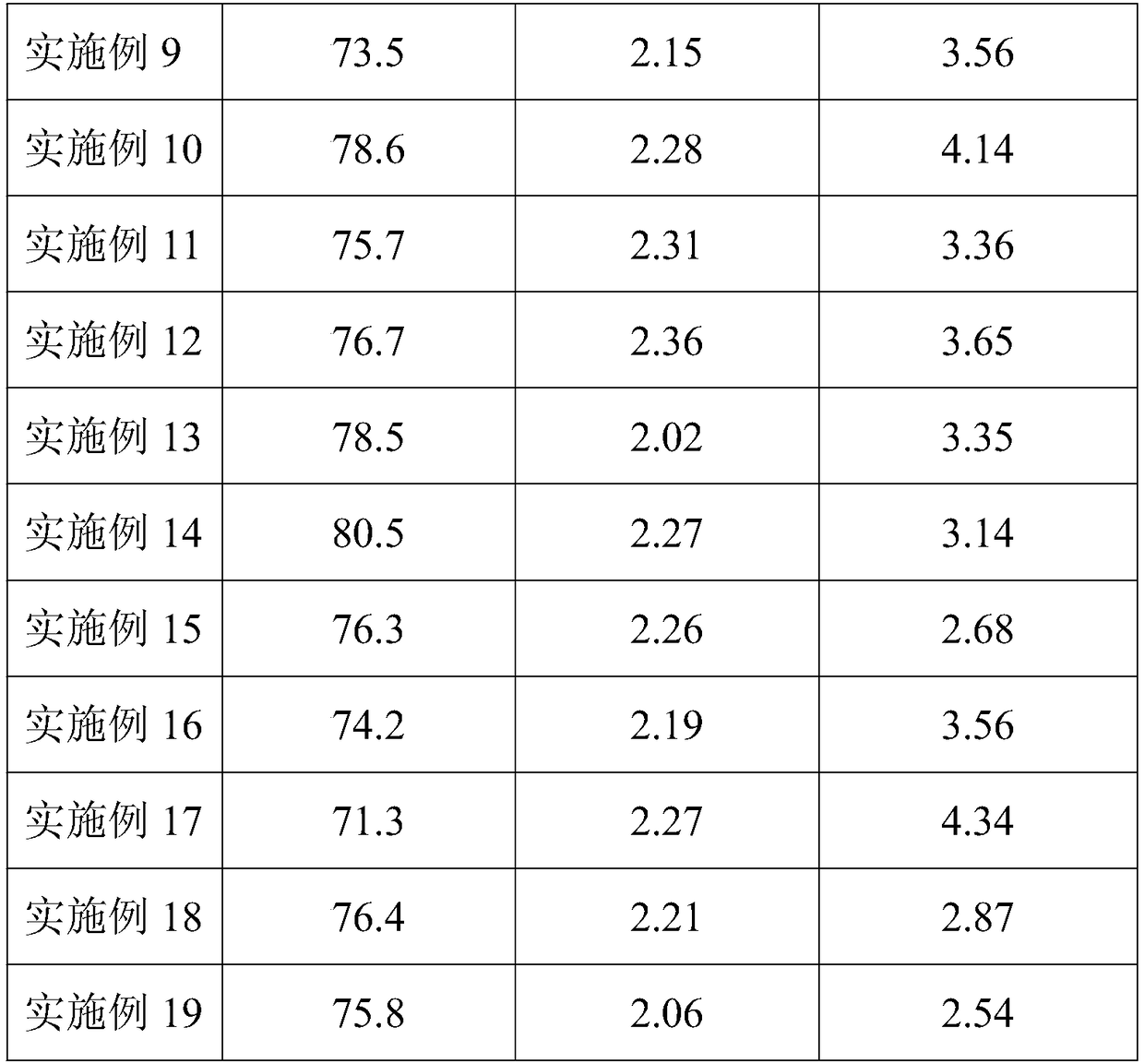

Examples

Embodiment 1

[0029] A gypsum-based sandless machine-sprayed lightweight plastering material, consisting of the following raw materials in parts by mass: 60g of hemihydrate gypsum, 0g of fly ash, 3g of expanded perlite, 0g of Portland cement, 0.17g of modified cellulose ether, 0.024g retarder, 0.3g thixotropic lubricant.

[0030] The hemihydrate gypsum is made by mixing desulfurized gypsum, phosphogypsum, natural gypsum and the like.

[0031] The modified cellulose ether is hydroxypropyl methylcellulose.

[0032] The retarder is composed of the following raw materials in parts by mass: 0.8 g of amino polyoxymethyl calcium salt, 0.1 g of borax, 0.01 g of sodium hexametaphosphate, and 0.01 g of mannitol.

[0033] The thixotropic lubricant is modified magnesium aluminum silicate.

[0034] The method comprises the following preparation steps: weighing each raw material component, stirring, adding to a hopper of a gypsum spraying machine, and adjusting the amount of water.

[0035] Said adjus...

Embodiment 2

[0037] A gypsum-based sandless machine-sprayed lightweight plastering material, which consists of the following raw materials in parts by mass: 70g of hemihydrate gypsum, 10g of fly ash, 10g of expanded perlite, 3g of Portland cement, 0.17g of modified cellulose ether, 0.024g retarder, 0.5g thixotropic lubricant.

[0038] The hemihydrate gypsum is desulfurized gypsum.

[0039] Further, the modified cellulose ether is hydroxyethyl methylcellulose.

[0040] The retarder is composed of the following raw materials in parts by mass: 1.0 g of amino polyoxymethyl calcium salt, 0.13 g of borax, 0.02 g of sodium hexametaphosphate, and 0.015 g of mannitol.

[0041] The thixotropic lubricant is modified magnesium aluminum silicate.

[0042] The method comprises the following preparation steps: weighing each raw material component, stirring, adding to a hopper of a gypsum spraying machine, and adjusting the amount of water.

[0043] Said adjustment of water volume is to add water to a co...

Embodiment 3

[0045] A gypsum-based sandless machine-sprayed lightweight plastering material, which is composed of the following raw materials in parts by mass: 90g of hemihydrate gypsum, 20g of fly ash, 15g of expanded perlite, 5g of Portland cement, 0.17g of modified cellulose ether, 0.024g retarder, 0.7g thixotropic lubricant.

[0046] The hemihydrate gypsum is phosphogypsum.

[0047] Further, the modified cellulose ether is obtained by mixing hydroxypropylmethylcellulose, hydroxyethylmethylcellulose, hydroxyethylcellulose and sodium carboxymethylcellulose.

[0048] The retarder is composed of the following raw materials in parts by mass: 1.2 g of amino polyoxymethyl calcium salt, 0.15 g of borax, 0.03 g of sodium hexametaphosphate, and 0.02 g of mannitol.

[0049] The thixotropic lubricant is modified magnesium aluminum silicate.

[0050] The method comprises the following preparation steps: weighing each raw material component, stirring, adding to a hopper of a gypsum spraying machin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com