Composite retarding material and preparation method thereof

A retarding material and retarding technology, applied in the field of retarding materials, can solve problems such as the inability to achieve retarding time and damage to the working performance of concrete

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

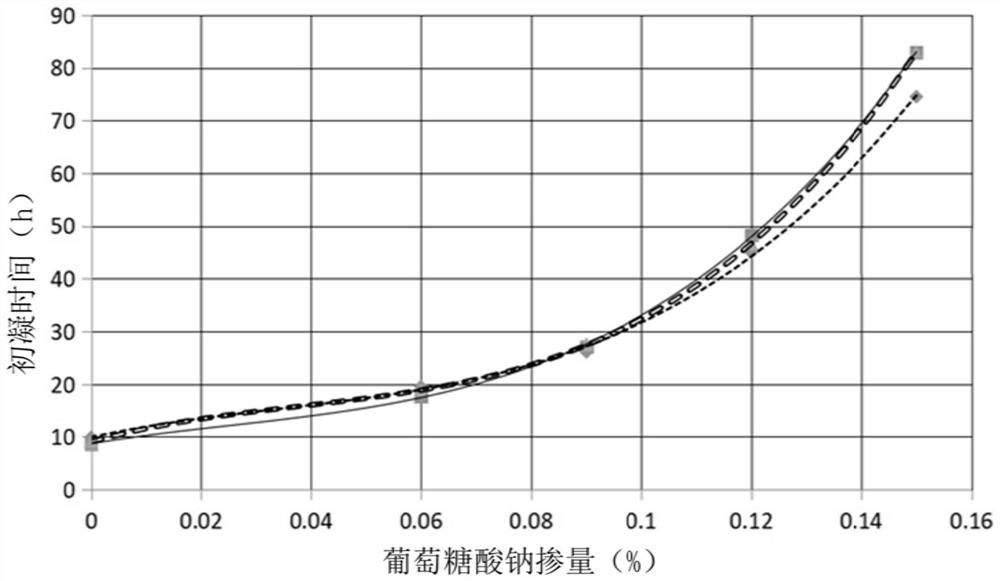

Method used

Image

Examples

Embodiment 1

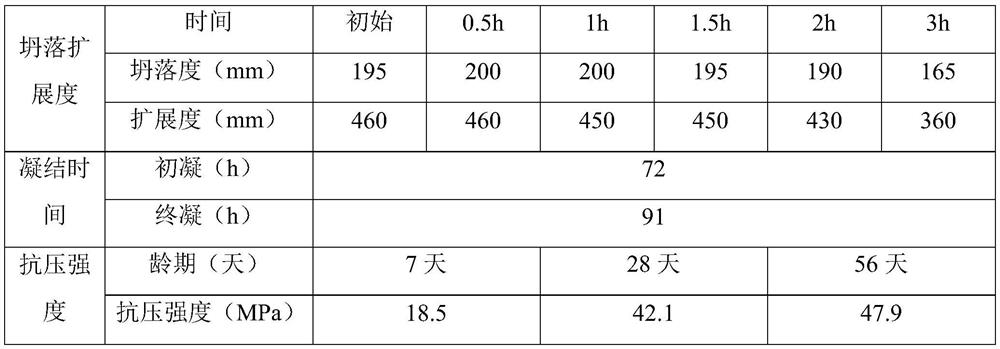

[0026] In this embodiment, the component materials and mass percentages of the composite retarding material are shown in Table 1. After the composite retarding material is prepared, the concrete is mixed according to the following ratio: the dosage of the composite retarding material is gelling The total amount of materials is 0.15%, the water-binder ratio is 0.43, and the fly ash content is 30%. The performance test results of the concrete mixed according to the above proportions are shown in Table 2.

[0027] Table 1 Proportions of various materials in composite retarding materials

[0028] sodium gluconate sucrose Hexametaphosphate tartaric acid 60% 30% 5% 5%

[0029] The concrete test result that table 2 adopts the composite type retarding material of embodiment 1 to mix

[0030]

[0031] The concrete in Example 1 has an initial setting time of 72 hours and a final setting time of 91 hours, which can fully meet the time requirements for soft...

Embodiment 2

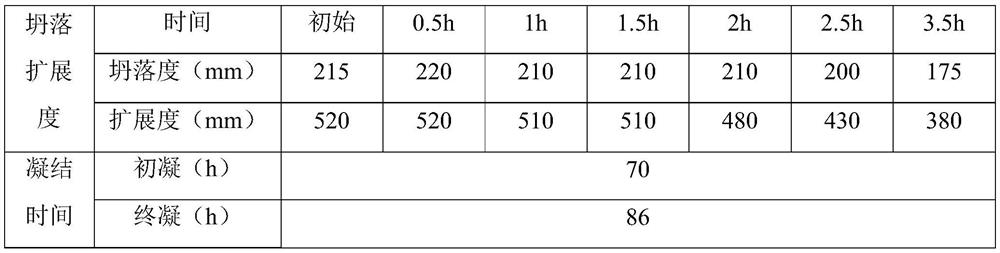

[0033] In this embodiment, the component materials and mass percentages of the composite retarding material are shown in Table 3. After the composite retarding material is prepared, the concrete is mixed according to the following ratio: the dosage of the composite retarding material is gelling The total amount of materials is 0.15%, the water-binder ratio is 0.38, and the fly ash content is 30%. The performance test results of the concrete mixed according to the above proportions are shown in Table 4.

[0034] Table 3 Proportions of various materials in composite retarding materials

[0035] sodium gluconate sucrose Hexametaphosphate sodium pyrophosphate Sodium citrate 55% 30% 6% 5% 4%

[0036] Table 4 adopts the concrete test result that the composite retarding material of embodiment 2 is mixed

[0037]

[0038]

[0039]The concrete in Example 2 has an initial setting time of 70 hours and a final setting time of 86 hours, which can meet ...

Embodiment 3

[0041] In this embodiment, the component materials and mass percentages of the composite retarding material are shown in Table 5. After the composite retarding material is prepared, the concrete is mixed according to the following ratio: the dosage of the composite retarding material is gelling The total amount of materials is 0.16%, the water-binder ratio is 0.48, and the fly ash content is 30%. The performance test results of the concrete mixed according to the above proportions are shown in Table 6.

[0042] Table 5 Proportions of various materials in composite retarding materials

[0043] sodium gluconate sucrose Hexametaphosphate Sodium dihydrogen phosphate boric acid Sodium citrate 20% 55% 10% 5% 5% 5%

[0044] Table 6 adopts the concrete test result mixed with the composite retarding material of embodiment 3

[0045]

[0046] The concrete in Example 3 has an initial setting time of 68 hours and a final setting time of 79 hours, whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com