Steel quenching filter device for continuous-annealing battery and process method

A technology of filtering device and process method, applied in the direction of filtering loop, filtering separation, filtering treatment, etc., can solve the problems of product quality degradation, increase product cost, battery shell perforation or canned battery, etc., and achieve thorough water purification and reduce waste. Qualified rate, the effect of eliminating iron ion residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

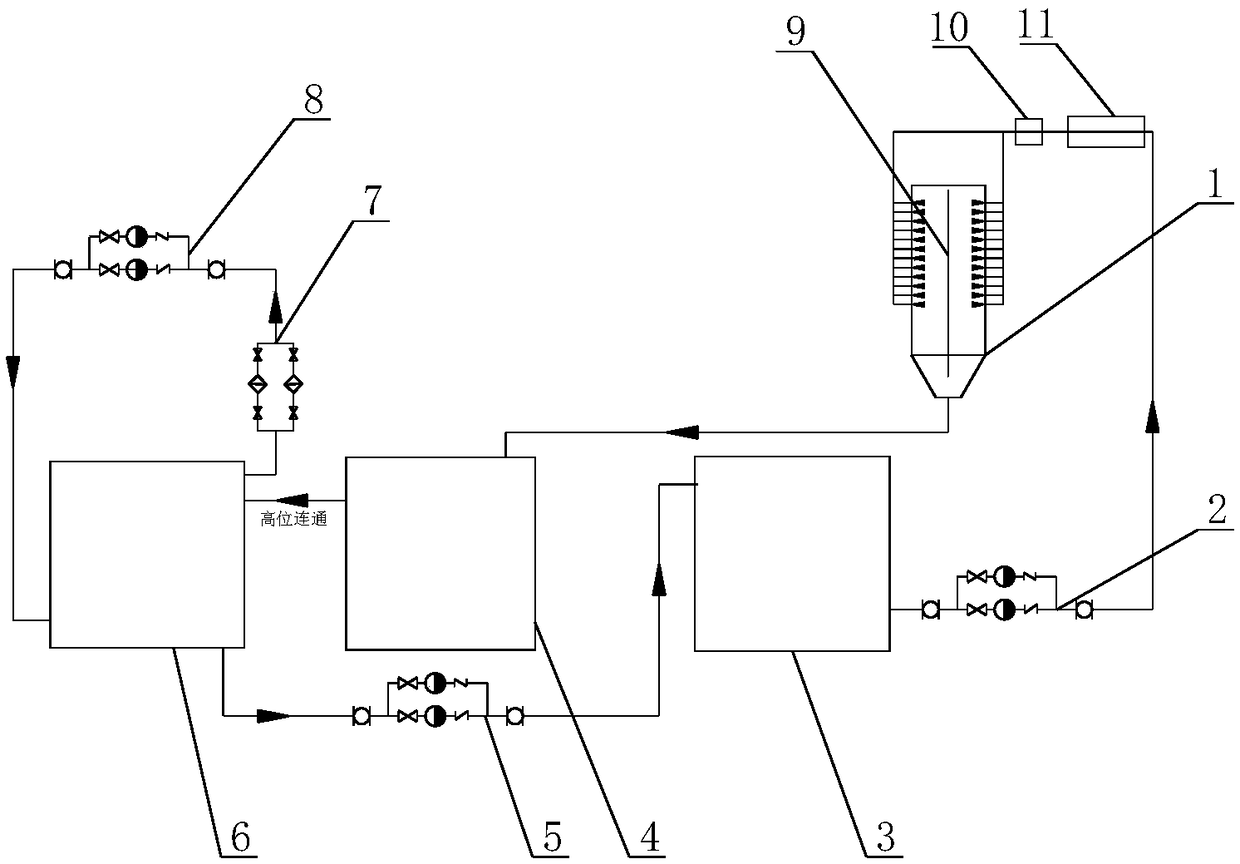

[0028] A steel quenching water filter device and process method for continuous retreat batteries, the device includes a spray working tank 1, a spray pump 2, a clean liquid tank 3, a first sedimentation tank 4, a replenishment pump 5, a second sedimentation tank 6 and Manganese sand filter 7, the spraying tank 1 is connected to the first settling tank 4 through pipelines, the first settling tank 4 is connected to the second settling tank 6 at a high level, and the second settling tank 6 is connected through the pipeline Connect with the manganese sand filter 7, the manganese sand filter 7 is connected with the second settling tank 6 through the pipeline of the self-circulating filter pump 8, and the second settling tank 6 is connected with the net liquid tank 3 through the pipeline of the replenishing water pump 5 , the clean liquid tank 3 is connected to the spray tank 1 through the spray pump 2.

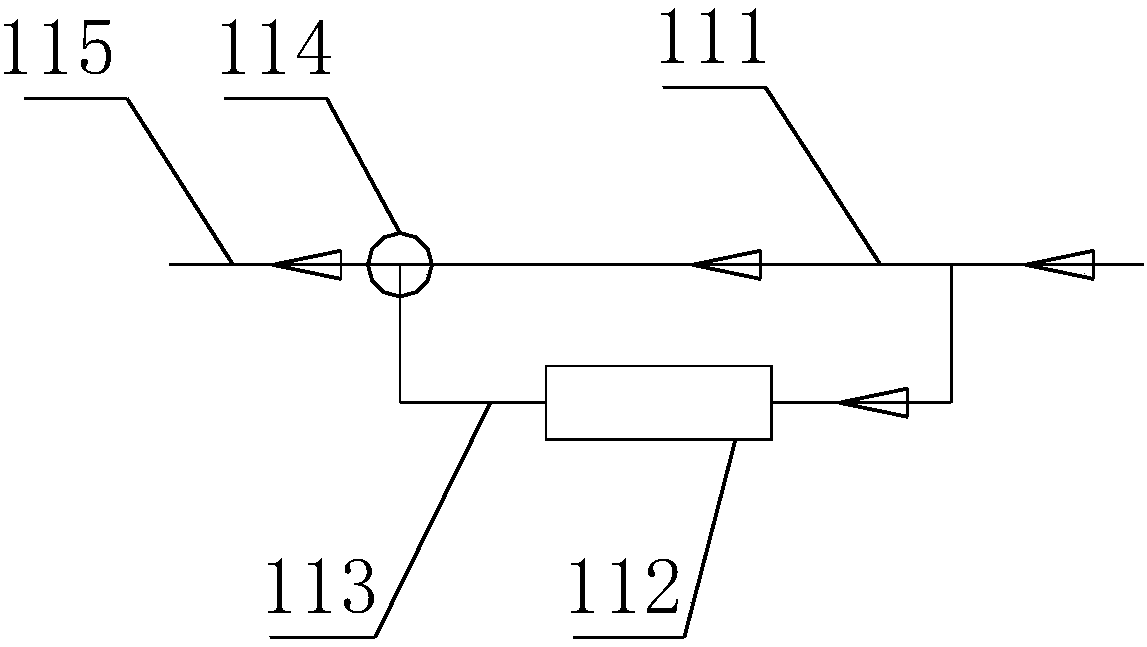

[0029] On the basis of the above-mentioned embodiment 1, the present invention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com