Preparation method and application of a nickel-based three-dimensional metal-organic framework catalyst

A technology of metal-organic frameworks and catalysts, applied in the fields of metal-organic framework materials, nanomaterials, and nanocatalysis, can solve the problems of limited practical applications, high prices, scarcity, etc., and achieve enhanced electrical conductivity and oxygen evolution catalytic performance, stability Good performance and easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1 A method for preparing nickel-based three-dimensional metal-organic frameworks

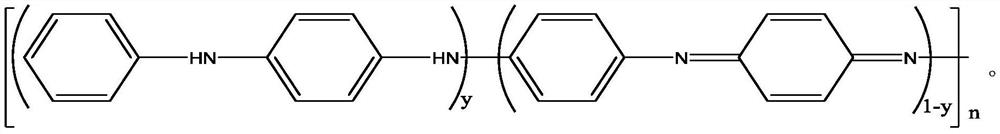

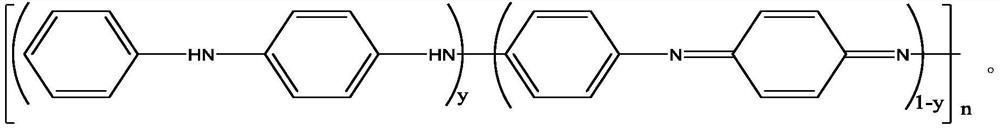

[0031] The activated nickel foam with an area of 0.5 cm × 1 cm was placed in a mixed solution consisting of 10 mL of water, 0.270 g of sodium sulfate and 40 μL of aniline, and electrodeposited for 25 min to obtain a composite material in which polyaniline was supported on foamed nickel, namely Ni@ PANI composite material;

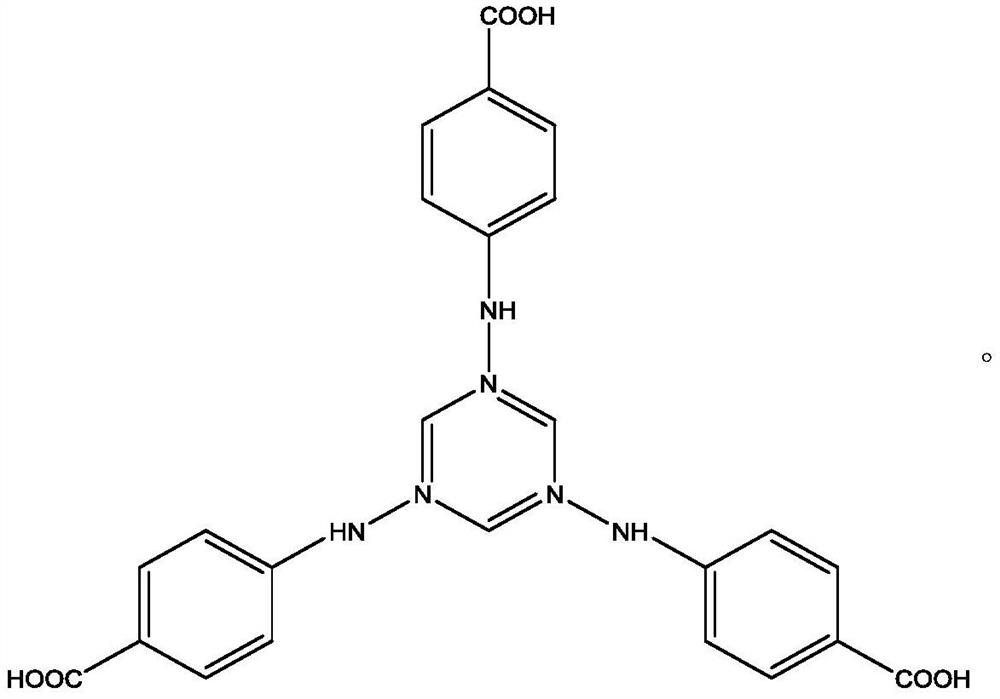

[0032] 0.045g H 3 The L ligand was dissolved in a mixed solution of 1mL DMF, 0.2mL absolute ethanol and 0.1mL water, then 0.025g cobalt nitrate was added, and Co(II)-MOF gel was prepared after ultrasonication;

[0033] 12 μL Co(II)-MOF gel was evenly coated on the Ni@PANI composite material, placed in a tube furnace, heated to 230 °C at a heating rate of 2 °C / min under air atmosphere, kept for 2 h, and then , cooled to room temperature at a cooling rate of 2°C / min; Ni@Co 2 o 3 / CN composite catalyst, that is, a nickel-based three-dimensional metal-organic...

Embodiment 2

[0039] Example 2 A method for preparing nickel-based three-dimensional metal-organic frameworks

[0040] The activated nickel foam with an area of 0.5 cm × 1 cm was placed in a mixed solution consisting of 10 mL of water, 0.290 g of sodium sulfate and 52 μL of aniline, and electrodeposited for 35 min to obtain a composite material in which polyaniline was loaded on foamed nickel, namely Ni@ PANI composite; 0.055g H 3 The L ligand was dissolved in a mixed solution of 1mL DMF, 0.2mL absolute ethanol and 0.1mL water, then 0.035g cobalt nitrate was added, and Co(II)-MOF gel was prepared after ultrasonication;

[0041] 15 μL of Co(II)-MOF gel was evenly coated on the Ni@PANI composite material, placed in a tube furnace, heated to 270 °C at a heating rate of 2 °C / min under an air atmosphere, kept for 2 h, and then , cooled to room temperature at a cooling rate of 2°C / min; Ni@Co 2 o 3 / CN composite catalyst, that is, a nickel-based three-dimensional metal-organic framework catal...

Embodiment 3

[0047] Example 3 A method for preparing a nickel-based three-dimensional metal-organic framework catalyst

[0048] The activated nickel foam with an area of 0.5 cm × 1 cm was placed in a mixed solution consisting of 10 mL of water, 0.280 g of sodium sulfate and 46 μL of aniline, and electrodeposited for 30 min to obtain a composite material in which polyaniline was loaded on foamed nickel, namely Ni@ PANI composite; mix 0.050g H 3 The L ligand was dissolved in a mixed solution of 1mL DMF, 0.2mL absolute ethanol and 0.1mL water, then 0.030g cobalt nitrate was added, and Co(II)-MOF gel was prepared after ultrasonication;

[0049] 14 μL of Co(II)-MOF gel was evenly coated on the Ni@PANI composite material, placed in a tube furnace, heated to 250 °C at a heating rate of 2 °C / min under an air atmosphere, kept for 2 h, and then , cooled to room temperature at a cooling rate of 2°C / min; Ni@Co 2 o 3 / CN composite catalyst, that is, a nickel-based three-dimensional metal-organic f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com