A kind of preparation method of c/c-tic carbon-ceramic composite material

A carbon-ceramic composite material and carbon fiber prefabricated body technology, which is applied in the direction of ceramic products, mechanical equipment, friction linings, etc., can solve the problem of affecting the performance of carbon-ceramic composite materials, improper control of the reaction process, metals, and fast reaction between melt and carbon. problems, to achieve the effects of low cost, short process cycle, and improved fracture toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

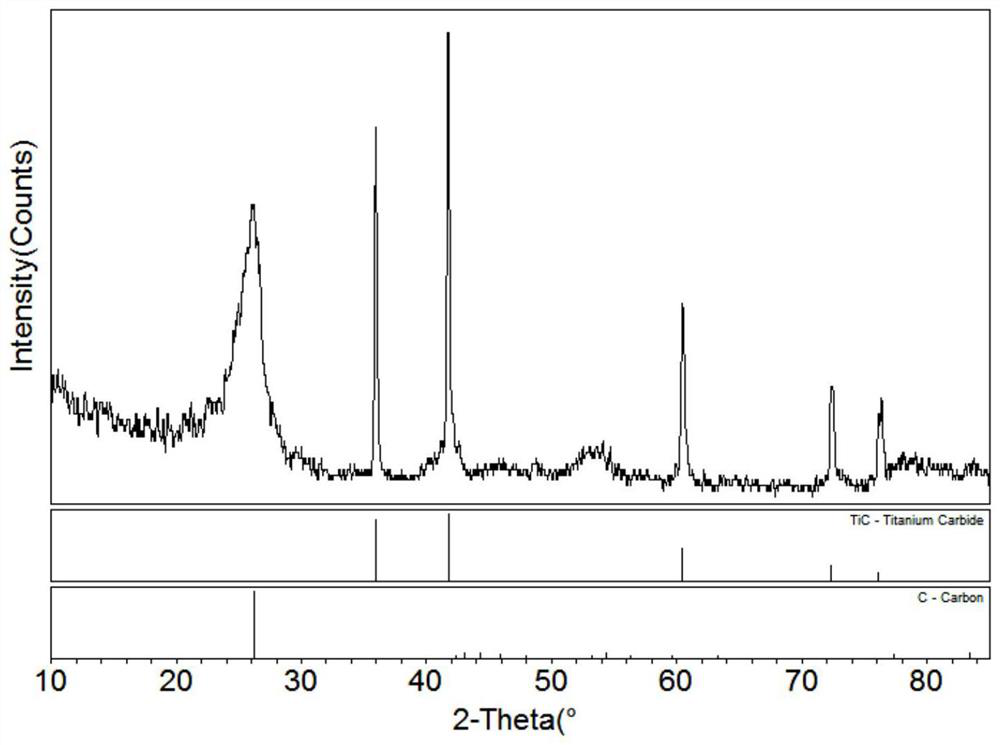

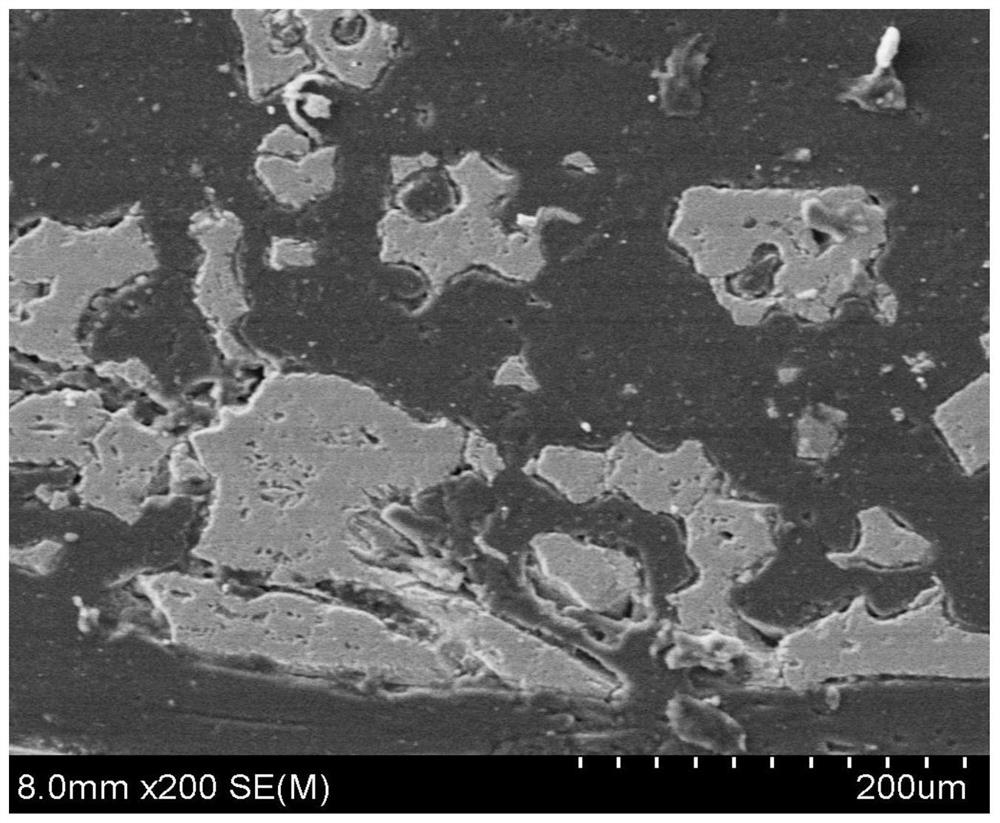

Image

Examples

Embodiment 1

[0034] Using continuous carbon fiber as raw material, the carbon fiber preform was prepared by the non-weft cloth laminated puncture process, and the fiber volume fraction of the carbon fiber preform was 35%. Put the carbon fiber prefabricated body in a vacuum of 8.0×10 -2 Heat to 1500°C under Pa and heat treatment for 1h to remove the adhesive on the surface of the fiber. A pyrolytic carbon protective coating is prepared on the carbon fiber surface of the heat-treated carbon fiber preform by using a chemical vapor deposition process, and the thickness of the pyrolytic carbon protective layer is 60 nm. The chemical vapor infiltration process is used to continue to deposit the matrix pyrolytic carbon inside the porous carbon fiber preform for subsequent reactions, and the porous carbon fiber preform is densified to obtain a porous C / C composite material preform, and the density control of the porous C / C composite material preform At 1.36g / cm 3 , the porosity is 32%. The poro...

Embodiment 2

[0038] Using continuous carbon fiber as raw material, the carbon fiber preform was prepared by using the lamination and piercing process without weft cloth, and the fiber volume fraction of the carbon fiber preform was 30%. Put the carbon fiber prefabricated body in a vacuum of 6.0×10 -2 Heat to 1600°C under Pa and heat treatment for 2 hours to remove the adhesive on the surface of the fiber. A pyrolytic carbon protective coating is prepared on the carbon fiber surface of the heat-treated carbon fiber preform by using a chemical vapor deposition process, and the thickness of the pyrolytic carbon protective layer is 100 nm. Using phenolic resin as the precursor, the matrix pyrolysis carbon for the subsequent reaction is prepared inside the porous carbon fiber prefabrication process by using the precursor impregnation and cracking process, and the porous carbon fiber prefabrication body is densified to obtain a porous C / C composite material prefabrication body, porous C / C compos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com