Method of preparing battery grade lithium hydroxide from active waste of lithium ion battery anode

A lithium-ion battery, positive electrode active technology, applied in the direction of lithium oxide;/hydroxide, battery recycling, recycling technology, etc., can solve the problems of complex separation and purification process, single research object, difficulty, etc., to avoid chemical agents The effect of high consumption, simple process and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

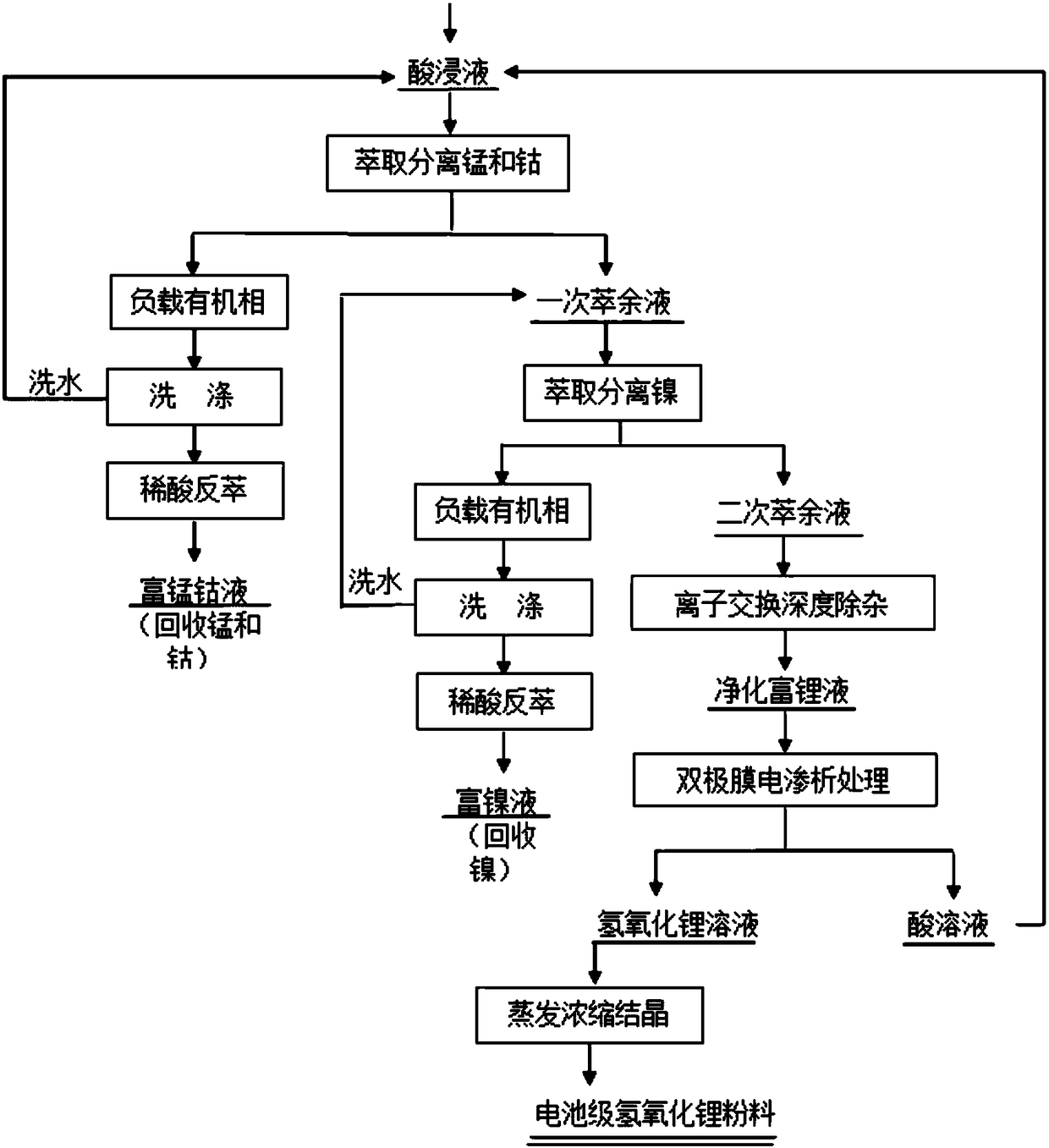

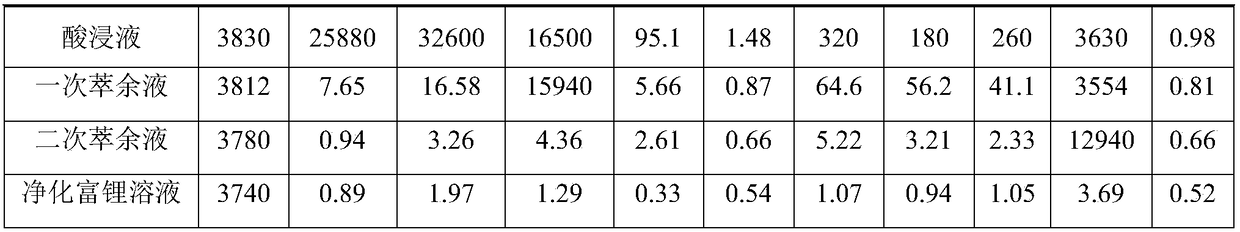

[0036] A kind of method of the present invention utilizes lithium-ion battery cathode waste to prepare battery-grade lithium hydroxide, and its process flow chart is as follows figure 1 shown, including the following steps:

[0037] (1) Nickel-cobalt-manganese ternary composite positive electrode material is treated by oxidative acid leaching, and the leaching agent is H 2 SO 4 solution and Na 2 S 2 o 8 The mixed solution of solution, obtains the sulfuric acid leaching liquor that 10L contains metal ions such as lithium ion;

[0038] (2) Add saponified P507 to extract manganese and cobalt in the sulfuric acid leaching solution after step (1), separate the aqueous phase and the loaded organic phase; add pure water to the loaded organic phase for washing, and incorporate the nickel-containing lithium washing water into the pre-extraction solution That is, in the sulfuric acid leaching solution of step (1), then adding a concentration of 1mol / L H in the loaded organic phase ...

Embodiment 2

[0047] A method for preparing battery-grade lithium hydroxide using lithium-ion battery positive electrode waste of the present invention comprises the following steps:

[0048] (1) Adopt the oxidative acid leaching method to process the positive electrode active waste of lithium ion battery. 2 o 2 The mixed solution of solution obtains 10L acid leach solution containing metal ions such as lithium ions;

[0049] (2) Add saponified Cyanex272 to extract manganese and cobalt in the hydrochloric acid leachate obtained in step (1), separate the aqueous phase and the loaded organic phase; the loaded organic phase is washed with pure water, and the washing water is incorporated into the acidic solution of step (1) The leaching solution is the pre-extraction solution, and then add dilute hydrochloric acid solution to the loaded organic phase for back extraction to obtain an enriched solution of manganese and cobalt, and the primary raffinate enters step (3) for processing;

[0050] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com