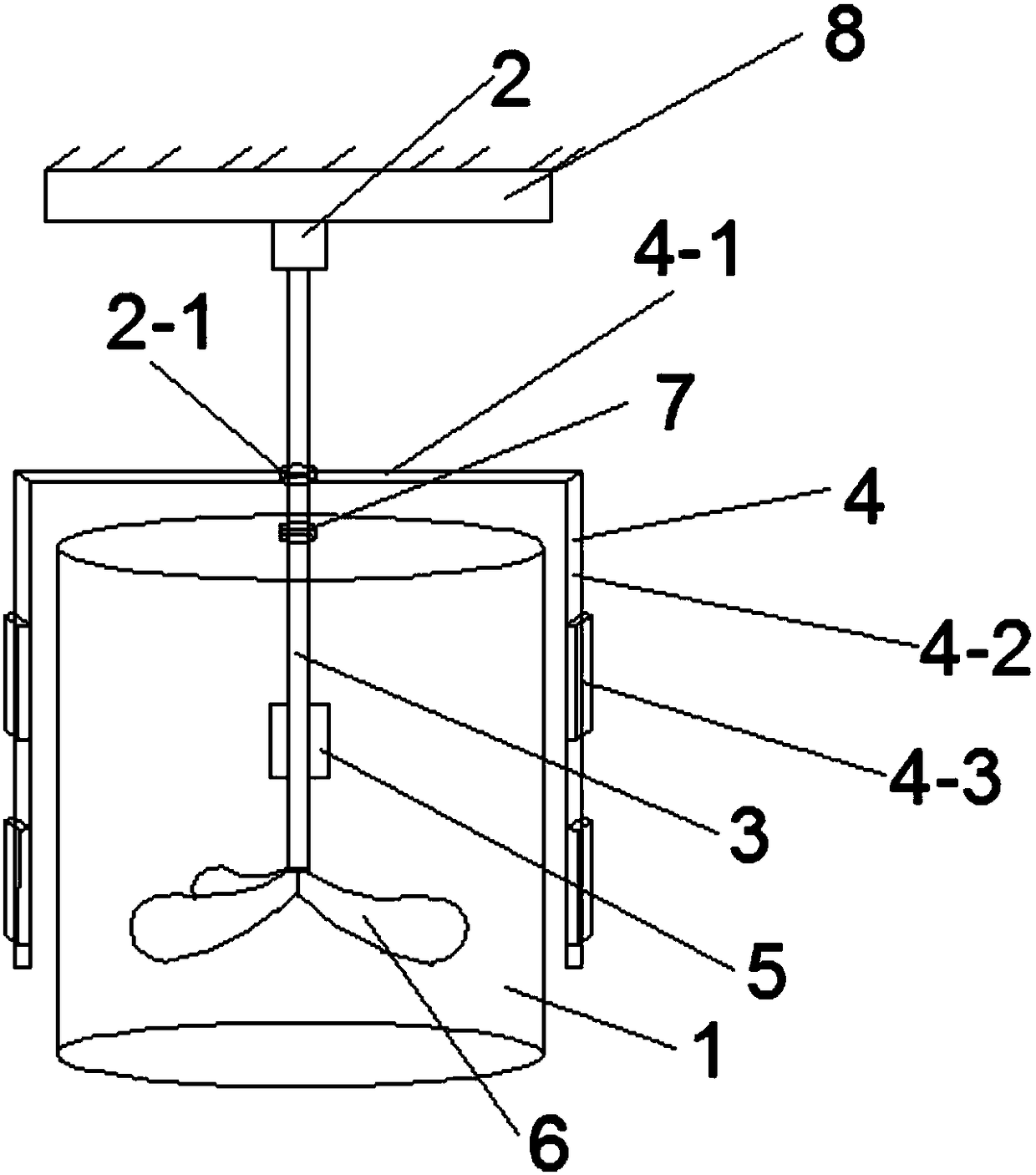

Preparation device for magnetization-based anatonosis wetting agent for water injection of coal seam

A preparation device and coal seam water injection technology, which is applied in safety devices, chemical/physical/physicochemical processes of energy application, mining equipment, etc., can solve the lack of mine magnetization-based permeability-enhancing wetting agent preparation devices and the use of surfactants Large volume, unsatisfactory water injection effect, etc., to achieve the effect of improved solution permeability and activity, easy equipment installation, and improved magnetization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: Weigh 7 parts of penetrating agent di-sec-octyl maleate sulfonate sodium, 1 part of polyethylene glycol, and 2 parts of inorganic salt sodium chloride, and prepare an additive with a mass fraction of 0.005%-0.2% The solution is passed into the preparation device of a magnetization-based permeability-enhancing wetting agent for coal seam water injection at a flow rate of 2 m / s, and is magnetized in a 300 mT magnetic field for ten minutes to obtain a magnetization-based permeability-enhancing wetting agent, and its surface tension is measured.

[0032] Case number

Embodiment 2

[0033] Embodiment 2: Weigh 7 parts of penetrating agent fatty alcohol polyoxyethylene ether (carbon chain length 7-9), 1 part of polyethylene glycol, 2 parts of inorganic salt sodium chloride, and prepare 1% concentration solution at 2m / s The flow rate is passed into the preparation device of a magnetization-based permeation-enhancing wetting agent for coal seam water injection, and the magnetization-based permeation-enhancing wetting agent is obtained after magnetization in a 300mT magnetic field for ten minutes, and is formulated as an additive with a mass fraction of 0.05%-0.1%. solution and measure its surface tension.

[0034] Case number

Embodiment 3

[0035] Example 3: Weigh 9 parts of fatty alcohol polyoxyethylene ether, 9 parts of di-octyl sodium sulfosuccinate, 12 parts of alkylphenol ether sulfosuccinate sodium salt, di-sec-octyl maleate 10 parts of sodium sulfonate, 30 parts of sodium chloride, 15 parts of polyethylene glycol, uniformly mixed with water and configured as a 0.015% additive solution, flowed into the special magnetization bucket of the magnetizer at a flow rate of 2m / s, in a 300mT magnetic field Magnetize for 10 minutes and measure its surface tension.

[0036] Case number

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com