Aspherical mirror embryo eliminating edge effect

A technology of aspheric mirror and edge effect, which is applied in the direction of mirrors, optical surface grinders, grinders, etc., and can solve problems such as stress and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

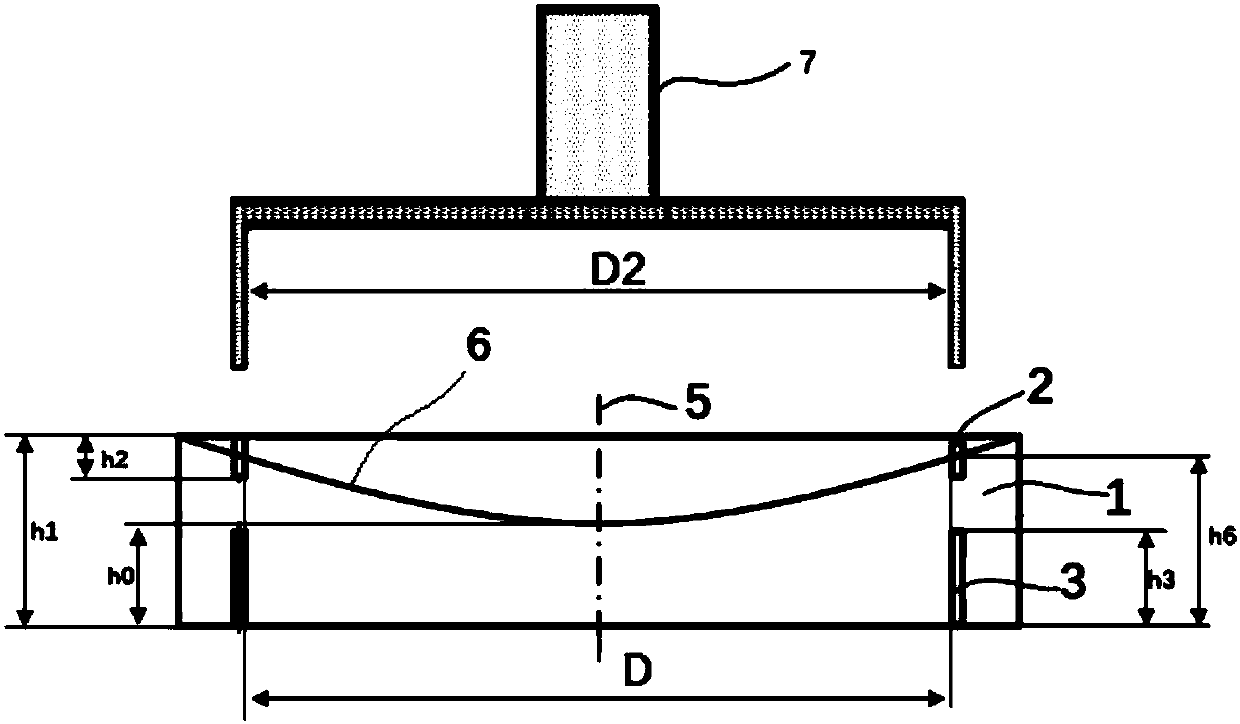

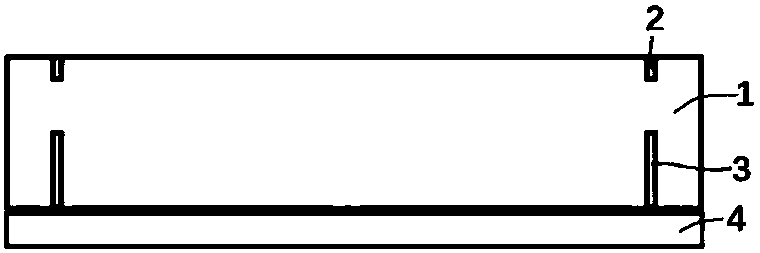

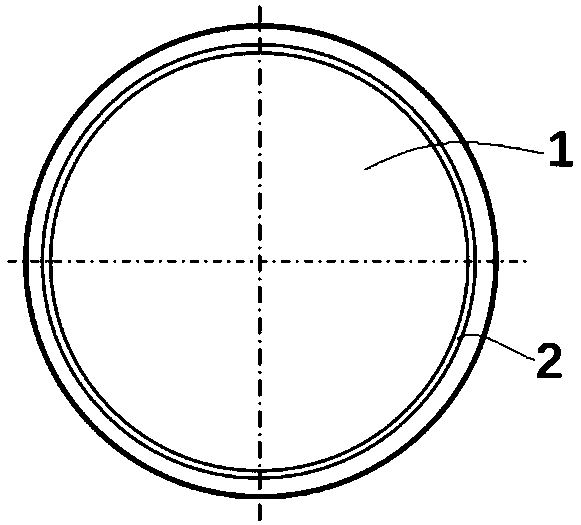

[0025] Embodiment one: as attached Figure 6 or Figure 7 An aspheric mirror blank with edge effect elimination shown: the aspherical mirror blank is composed of a cylindrical mirror blank 1, which includes a first end face 8, a second end face 9, a cylindrical side wall 10, an aspheric surface The structure 6 is arranged on the first end surface 8, and it is characterized in that the aspheric surface structure is also provided with a first circular groove, wherein the rotation axis of the first circular groove coincides with the rotation axis of the aspheric surface, and the inner diameter of the first circular groove is larger than the diameter of the aspheric surface.

[0026] Attached below figure 1 , taking the rotating concave aspheric mirror with the machining diameter as D and the center thickness as h0 as an example to introduce the specific steps of using the above-mentioned cylindrical mirror blank to process the aspheric surface,

[0027] Step 1: Process a cylind...

Embodiment 2

[0032] Embodiment 2: On the basis of Embodiment 1, the depth of the first circular groove is greater than or equal to 2 mm, so that edge collapse of the aspheric surface can be effectively avoided during later trimming.

Embodiment 3

[0033] Embodiment three: as attached figure 1 - attached Figure 5 As shown, on the basis of the first embodiment, the second end face is also provided with a second end face round groove 3, wherein the rotation axis of the second end face round groove coincides with the aspheric rotation axis, and the second end face round groove and the first round groove The groove width and inner diameter are equal, and the depth of the circular groove 3 on the second end surface is h3, which satisfies h2+h3<h1. After the second end surface circular groove is punched on the second end surface of the cylindrical mirror blank, it is more convenient to take out the aspheric mirror with only a small amount of grinding during subsequent edge trimming, and at the same time further reduce the grinding stress deformation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com