Supercritical extracting method of ginger oil

A technology of supercritical extraction and ginger oil, applied in the direction of producing fat, fat oil/fat production, etc., can solve problems such as damage to effective ingredients, low extraction rate, pollution, etc., and achieves low solvent consumption, short extraction period and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

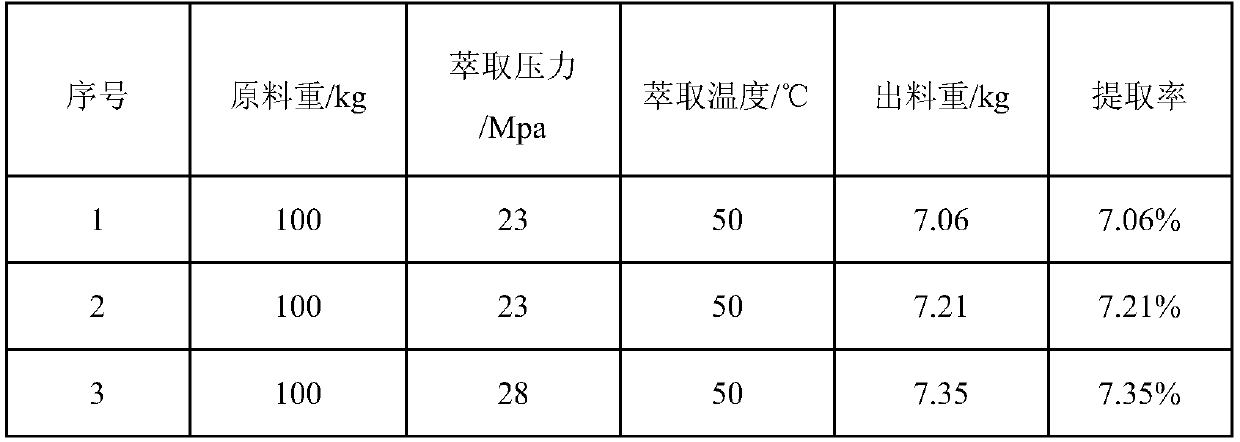

[0017] The implementation method is as follows: select fresh ginger as raw material, remove surface silt and other impurities, then wash it with clear water, put the washed ginger into an oven, and dry it to a water content of 12% at a temperature of 55°C, and dry the dried ginger to a water content of 12%. Ginger is put into pulverizer and is pulverized into 65 purpose ginger powder; Take ginger powder 100kg and put it into the material barrel of extraction kettle, inject carbon dioxide gas into extraction kettle, keep the temperature and pressure of carbon dioxide gas in the extraction kettle at its supercritical state and Natural raw material contact; the extraction temperature is 50°C, the pressure is 23MPa; the flow rate of carbon dioxide gas through the extraction kettle is 1.1t / h, and the extraction time is 3h, so that the ginger oil in the ginger powder is fully dissolved in the supercritical fluid, from The outlet of the separation kettle collects the fluid containing ...

Embodiment 3

[0019] The implementation method is as follows: select fresh ginger as raw material, remove surface silt and other impurities, then wash it with clear water, put the washed ginger into an oven, and dry it to a water content of 12% at a temperature of 55°C, and dry the dried ginger to a water content of 12%. Ginger is put into pulverizer and is pulverized into 65 purpose ginger powder; Take ginger powder 100kg and put it into the material barrel of extraction kettle, inject carbon dioxide gas into extraction kettle, keep the temperature and pressure of carbon dioxide gas in the extraction kettle at its supercritical state and Natural raw material contact; the extraction temperature is 50°C, the pressure is 28MPa; the flow rate of carbon dioxide gas through the extraction kettle is 1.1t / h, and the extraction time is 3h, so that the ginger oil in the ginger powder is fully dissolved in the supercritical fluid, from The outlet of the separation kettle collects the fluid containing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com