Composite functional additive of emulsified oil for hydraulic support and preparation method of composite functional additive

A composite function, hydraulic support technology, used in additives, petroleum industry, lubricating compositions, etc., can solve problems such as single performance and troublesome emulsified oil production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

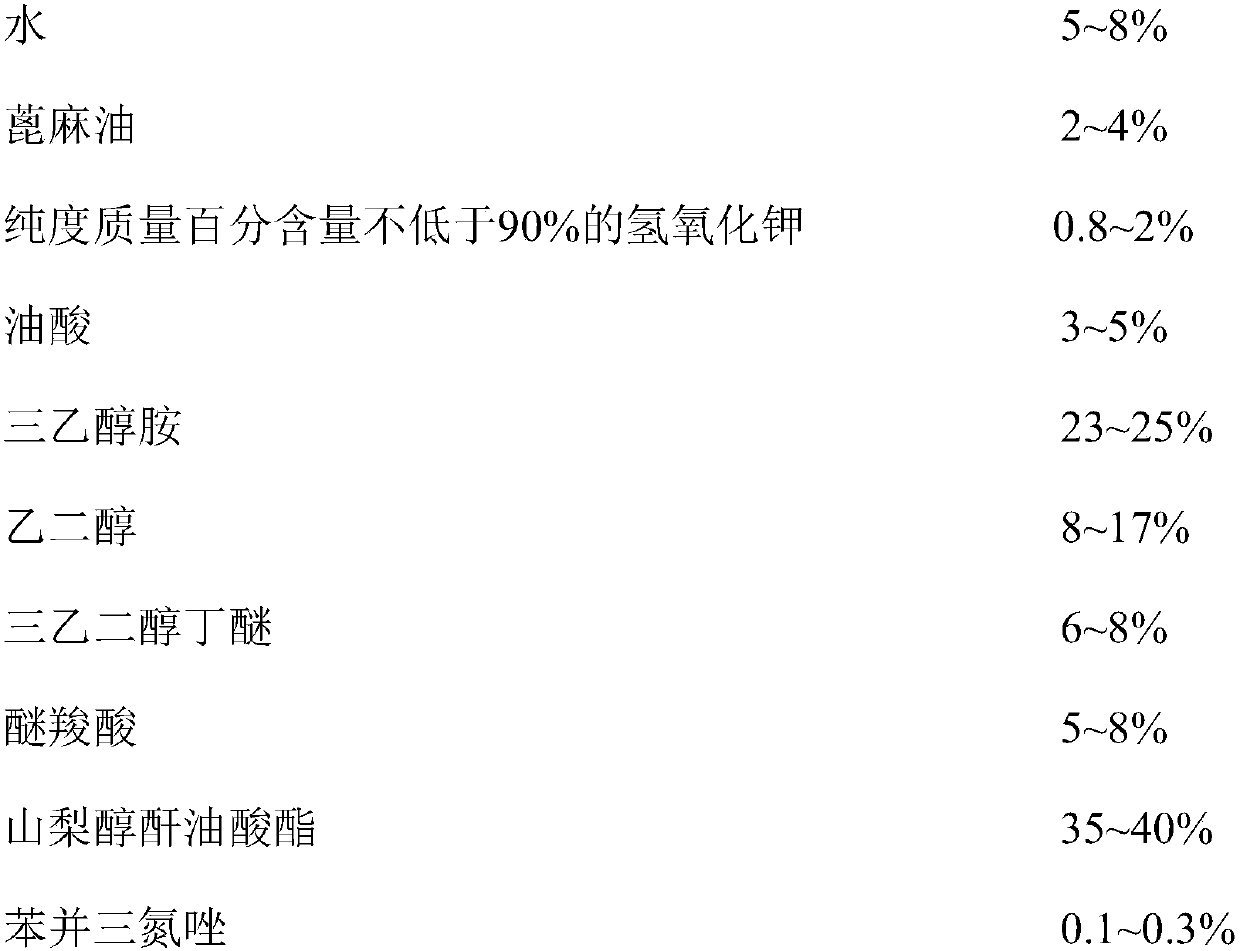

[0014] A composite functional additive for emulsified oil for hydraulic supports contains the following components, the sum of the mass percentages of each component is 100%, and the mass percentages of each component are respectively:

[0015]

[0016] The preparation method of the composite functional additive for hydraulic support emulsified oil is: (1) according to their respective mass percentages, take the water, potassium hydroxide and castor oil into the reaction kettle, stir, and heat up to 85-95 ° C, Saponification reaction was carried out at this temperature for 1 hour to prepare castor oil potassium hydroxide soap. (2) Then add oleic acid and triethanolamine into the reaction kettle according to their respective mass percentages, stir, heat up to 90-100°C, and saponify at this temperature for 1.5 hours to prepare oleic acid triethanolamine soap. (3) Add the castor oil potassium hydroxide soap and oleic acid triethanolamine soap into the reaction kettle, and then...

Embodiment 2

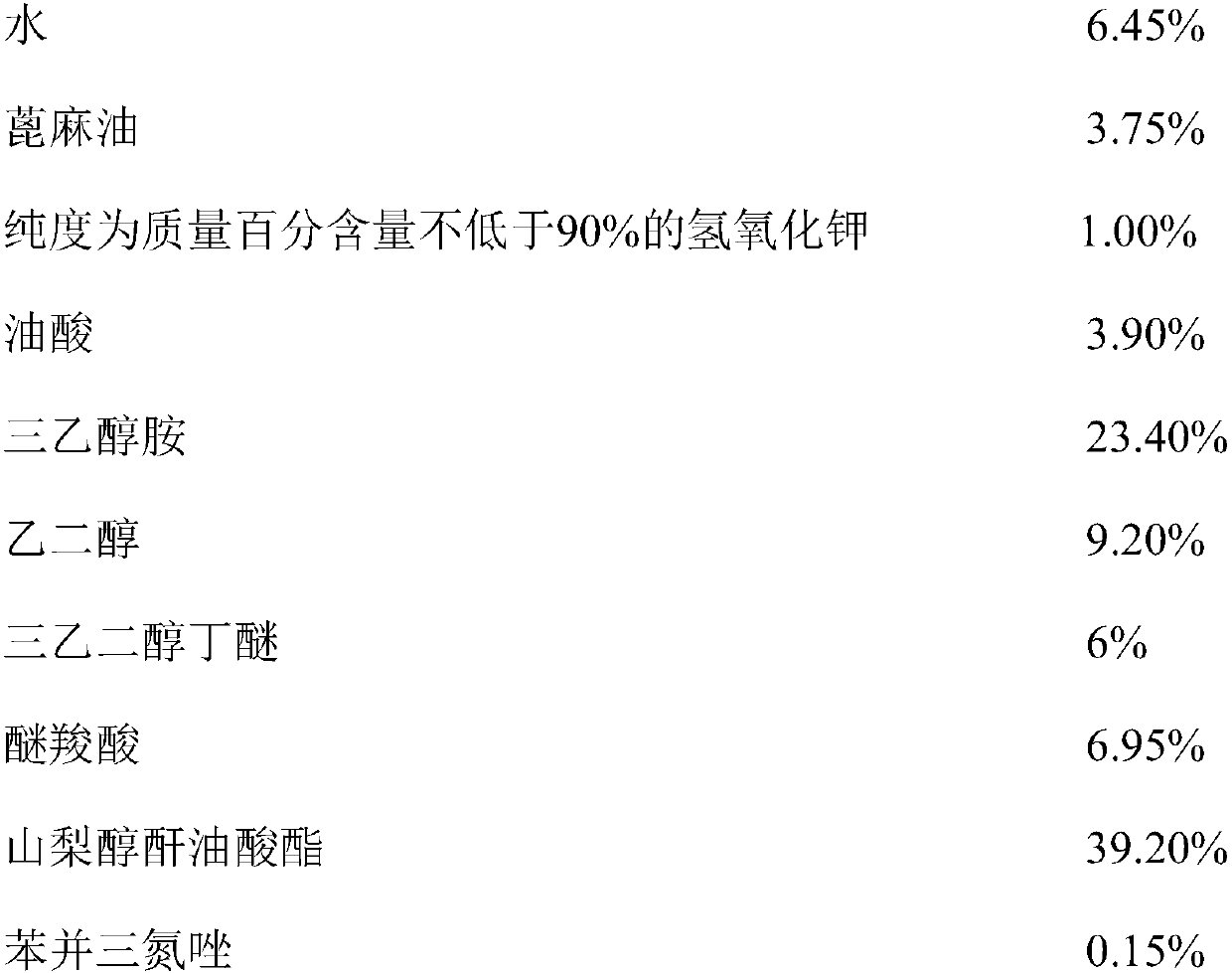

[0021] A composite functional additive for emulsified oil for hydraulic supports contains the following components, the sum of the mass percentages of each component is 100%, and the mass percentages of each component are respectively:

[0022]

[0023]

[0024] The preparation method of the composite functional additive for hydraulic support emulsified oil is: (1) according to their respective mass percentages, take the water, potassium hydroxide and castor oil into the reaction kettle, stir, and heat up to 85-95 ° C, Saponification reaction was carried out at this temperature for 1 hour to prepare castor oil potassium hydroxide soap. (2) Then add oleic acid and triethanolamine into the reaction kettle according to their respective mass percentages, stir, heat up to 90-100°C, and saponify at this temperature for 1.5 hours to prepare oleic acid triethanolamine soap. (3) Add the castor oil potassium hydroxide soap and oleic acid triethanolamine soap into the reaction kett...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com