Degradable polymer microspheres and preparing method thereof

A technology for degrading polymers and polymers, applied in the field of degradable polymer microspheres and their preparation, can solve the problems of polymer microspheres adhesion, agglomeration, and poor controllability of the size of the microspheres, etc., to prevent adhesion , The effect of uniform particle size distribution, simple and rapid preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] see Figure 1 to Figure 3, in some embodiments of the present invention, a method for preparing degradable polymer microspheres, comprising the following steps:

[0046] S1: dissolving the polymer in a volatile organic solvent to obtain a polymer solution;

[0047] S2: Under stirring conditions, inject the polymer solution obtained in S1 into the emulsifier aqueous solution through a thin tube using a flow pump;

[0048] S3: After the mixing is completed, continue stirring to remove the organic solvent to obtain a suspension;

[0049] S4: leave the suspension obtained in S3 to allow the polymer microspheres to fully settle, and discard the supernatant;

[0050] S5: The polymer microspheres are collected by filtration, washed and dried to obtain degradable polymer microspheres.

[0051] As mentioned above, the present invention combines the characteristics of the microfluidic method, and uses a thin pipeline in the emulsification-solidification method to limit the siz...

Embodiment 1

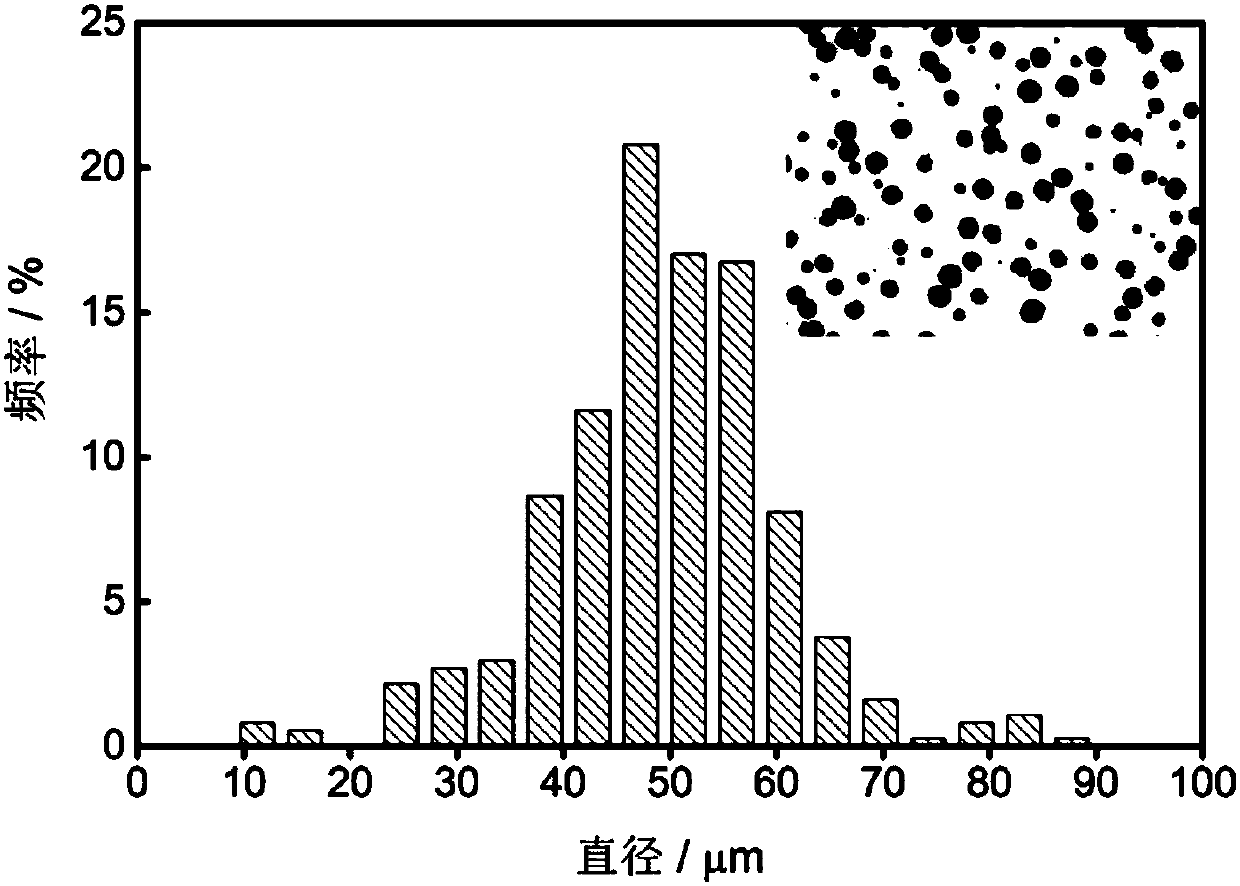

[0069] Accurately weigh 15g of L-polylactic acid (intrinsic viscosity 1.18dL / g, solvent chloroform) and dissolve it in 250mL of analytically pure dichloromethane as the organic phase; at the same time prepare 2500mL of PVA-210 aqueous solution as the water phase; (600rpm), using a peristaltic pump to slowly inject the above organic phase under the PVA aqueous solution at an injection rate of 4mL / min through a 12G needle. After the injection was completed, the mixture was stirred at 360 rpm for 12 hours to remove the solvent. Then let it stand for 1 hour, discard the supernatant, filter the precipitate, wash with deionized water three times, and freeze-dry to obtain polylactic acid microspheres.

Embodiment 2

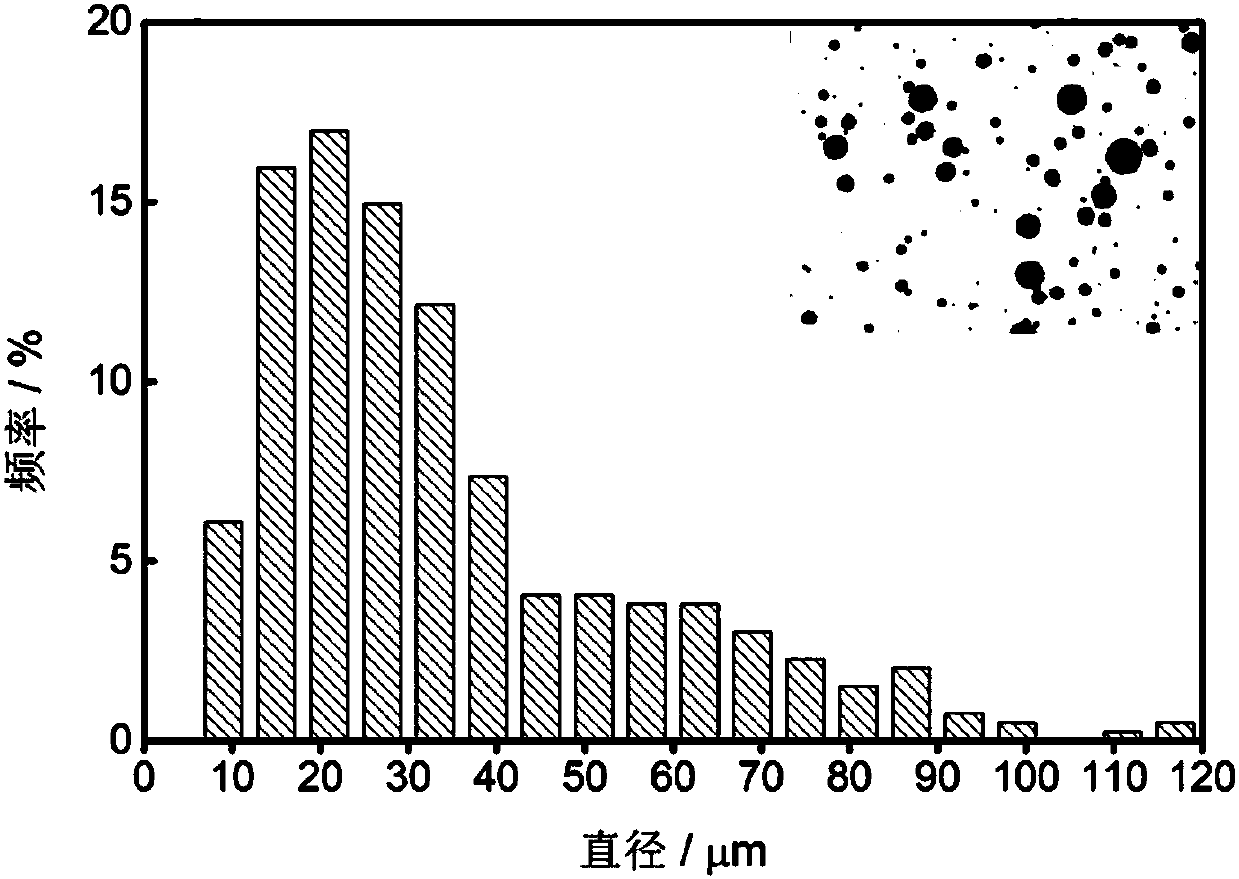

[0070] Embodiment 2 (instilled in control group)

[0071] The preparation method of the organic phase and the aqueous phase is the same as in Example 1; the preparation method of the microspheres is the same as in Example 1 except for the following differences:

[0072] During the addition of the organic phase, the needle is positioned above the liquid surface of the water phase, and the organic phase is added to the water phase in the form of droplets.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com