Edible mushroom culture medium

A technology for cultivation substrate and edible fungi, applied in cultivation, plant cultivation, mushroom cultivation and other directions, can solve the problems of limitation, poor water holding capacity, small size of fruiting body, etc., and achieve the effect of enhancing the anti-mildew and antibacterial ability and enhancing the easy decomposition performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] An edible mushroom cultivation substrate is prepared from the following raw materials in parts by weight: 50-58 parts of rice husks, 8-12 parts of activated carbon, 9-13 parts of ginkgo leaves, 17-25 parts of wheat bran, 1.5-2.5 parts of lime, 1.5-2.5 parts of sucrose, 0.4-0.6 parts of gypsum. The activated carbon is preferably activated carbon prepared from rice husks.

[0016] The preparation method of above-mentioned edible fungus cultivation substrate, comprises the following steps:

[0017] (1) Prepare the lime into lime water with a mass concentration of 4-5%, crush the ginkgo leaves, mix them with the rice husk and the lime water evenly, and let it stand for more than 3-5 minutes; first use lime on the rice husk and ginkgo leaves Water treatment can remove surface wax, making it easy to be decomposed and absorbed;

[0018] (2) Add activated carbon, wheat bran, sucrose, gypsum and water to make the final material moisture content 60-70%;

[0019] (3) Sterilize ...

Embodiment 2

[0021] An edible mushroom cultivation substrate is prepared from the following raw materials in parts by weight: 54 parts of rice husk, 10 parts of rice husk activated carbon, 11 parts of ginkgo biloba leaves, 21 parts of wheat bran, 2 parts of quicklime, 2 parts of sucrose and 0.5 part of gypsum.

[0022] The preparation method of above-mentioned edible fungus cultivation substrate, comprises the following steps:

[0023] (1) The lime is prepared into lime water with a mass concentration of 4.5%, the ginkgo leaves are crushed, and the rice husk is mixed with the lime water evenly, and left to stand for 10 minutes;

[0024] (2) Add activated carbon, wheat bran, sucrose, gypsum and water to make the final material moisture content 65%;

[0025] (3) Pack into bags and sterilize at 121°C for 0.5h to make clinker.

Embodiment 3

[0027] An edible mushroom cultivation substrate is prepared from the following raw materials in parts by weight: 58 parts of rice husk, 10 parts of rice husk activated carbon, 11 parts of ginkgo biloba leaves, 17 parts of wheat bran, 2 parts of quicklime, 2 parts of sucrose and 0.5 part of gypsum.

[0028] The preparation method of above-mentioned edible fungus cultivation substrate, comprises the following steps:

[0029] (1) Prepare lime into lime water with a mass concentration of 4%, crush ginkgo leaves, mix with rice husk and lime water evenly, and let stand for 10 minutes;

[0030] (2) Add activated carbon, wheat bran, sucrose, gypsum and water to make the final material moisture content 70%;

[0031] (3) Sterilize at 121°C for 0.5h to make clinker.

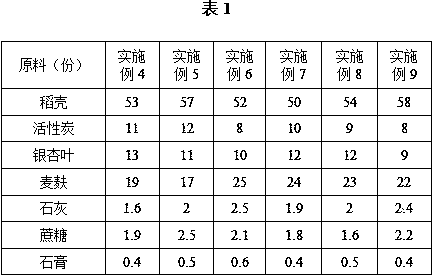

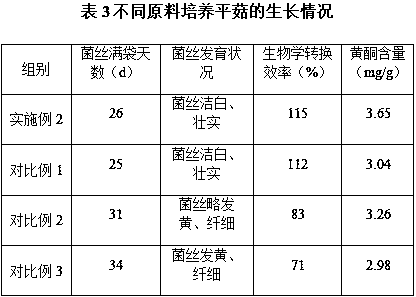

[0032] The formula of the edible fungi cultivation substrate provided by the embodiment 4-15 of the present invention is shown in Table 1-2, and the others are the same as in the embodiment 2.

[0033]

[0034]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com