Expansion graphite waste water treatment method

A technology for expanded graphite and wastewater treatment, applied in water/sewage treatment, neutralized water/sewage treatment, water/sewage treatment equipment, etc. Deal with the problems of high cost and achieve the effect of avoiding secondary pollution, improving production efficiency and improving recycling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

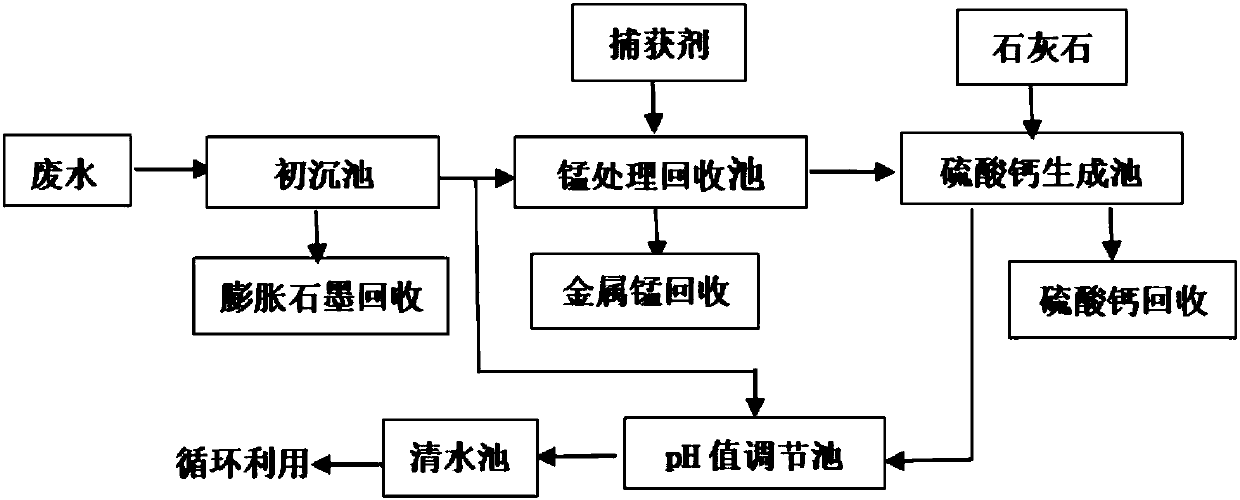

Image

Examples

Embodiment 1

[0037] A method for treating expanded graphite waste water, comprising the following steps:

[0038] (1) Expanded graphite waste water enters the primary sedimentation tank, after a period of static sedimentation, the hydraulic retention time is 1h, most of the expanded graphite powder settles to the bottom of the tank through natural precipitation, and the expanded graphite powder is collected at the bottom of the tank at a fixed time every day for recycling , The recovery rate of expanded graphite powder can reach 98.6%.

[0039](2) the waste water that step (1) is processed is sent into the manganese treatment recovery pond, adds calcium peroxide 1.8g / L, produces manganese precipitate, i.e. brown hydrated manganese dioxide precipitation, after the static settling of 0.5h, The hydrated manganese dioxide at the bottom of the pond is regularly recovered every day, and the recovery rate of metal manganese reaches 94.5%. At this time, the waste water changes from acidic to alkal...

Embodiment 2

[0043] A method for treating expanded graphite waste water, comprising the following steps:

[0044] (1) Expanded graphite waste water enters the primary sedimentation tank, after a period of static sedimentation, the hydraulic retention time is 2h, most of the expanded graphite powder settles to the bottom of the tank through natural precipitation, and the expanded graphite powder is collected at the bottom of the tank at a fixed time every day for recycling , The recovery rate of expanded graphite powder can reach 99.1%.

[0045] (2) Send the waste water treated in step (1) into the manganese treatment recovery pool, add calcium peroxide 2.0g / L, produce manganese precipitate, that is, brown hydrated manganese dioxide, after 1h of static precipitation, regularly The hydrated manganese dioxide at the bottom of the recovery pond, the metal manganese recovery rate reaches 96.3%, at this time, the waste water changes from the original acidity to the alkaline waste water, and the ...

Embodiment 3

[0049] A method for treating expanded graphite waste water, comprising the following steps:

[0050] (1) Expanded graphite wastewater enters the primary sedimentation tank, after a period of static sedimentation, the hydraulic retention time is 3h, most of the expanded graphite powder settles to the bottom of the tank through natural precipitation, and the expanded graphite powder is collected at the bottom of the tank at a fixed time every day for recycling , The recovery rate of expanded graphite powder can reach 99.7%.

[0051] (2) The waste water treated in step (1) is sent to the manganese treatment recovery pool, and calcium peroxide 2.2g / L is added to produce manganese deposits, i.e. brown hydrated manganese dioxide. After 1.5h of static precipitation, every day The hydrated manganese dioxide at the bottom of the tank is regularly recovered, and the metal manganese recovery rate reaches 97.8%. At this time, the waste water changes from the original acidity to the alkali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com