Hardware machining method

A processing method and hardware technology, applied in metal processing equipment, manufacturing tools, grinding machines, etc., can solve the problems of low grinding and polishing efficiency, inability to grind parts on both sides, etc., and achieve the effect of speeding up grinding efficiency, uniform grinding, and improving grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below by means of specific embodiments:

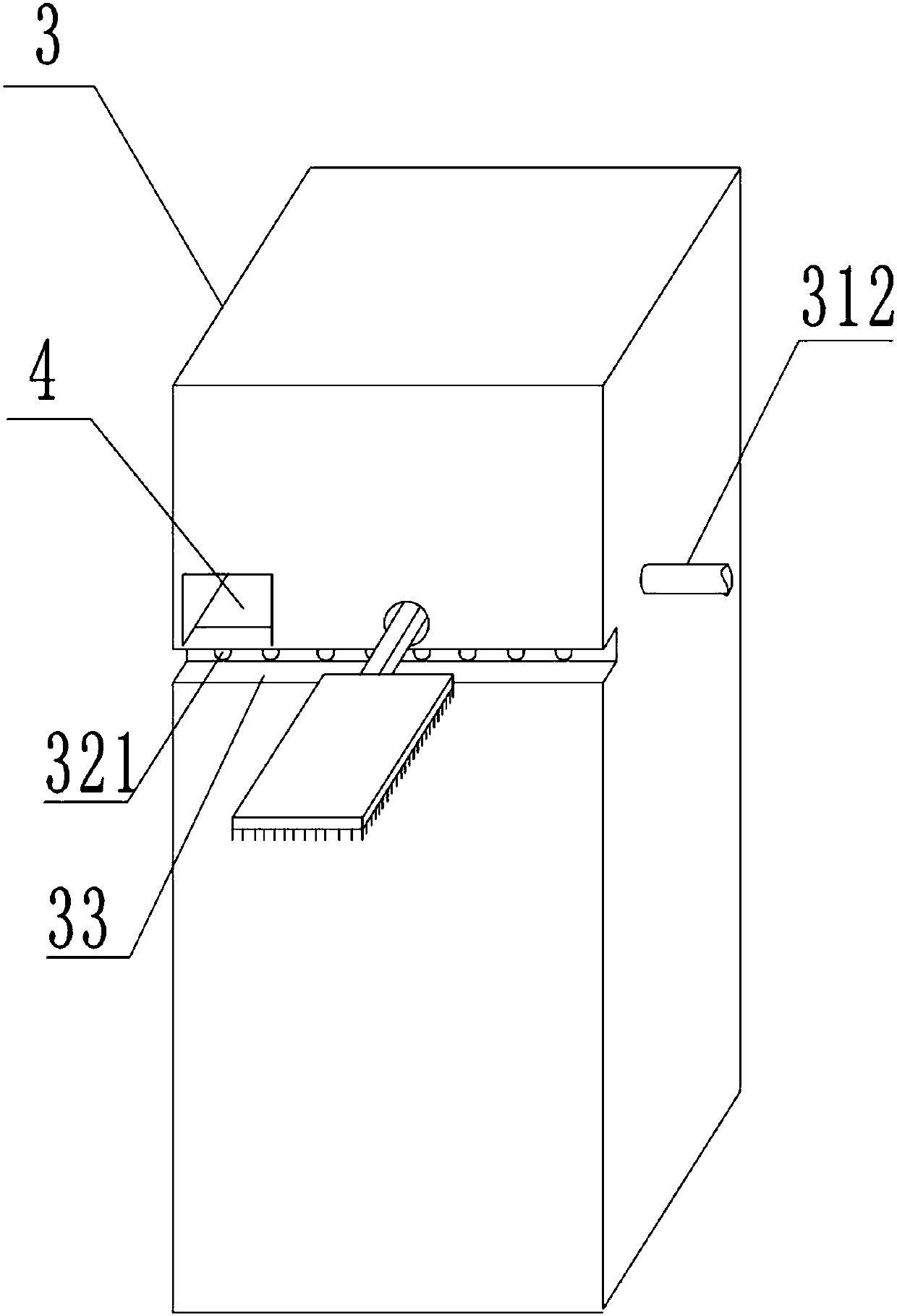

[0029] The reference signs in the accompanying drawings of the specification include: the conveying surface 1, the grinding layer 11, the dust collecting tank 111, the grinding part 2, the cleaning brush 22, the plate body 211, the stop rod 212, the arc-shaped outer cover 213, and the arc-shaped limit block 2131 , Baffle plate 2132, Dust suction part 3, Dust suction tube 31, Dust suction pipe 311, Dust discharge pipe 312, Bar box 32, Dust suction hole 321, Chute 33, Placement cavity 34, Strip chute 341, Fixed Plate 342, insertion port 4, threaded rod 5, push rod 6, extension rod 61, slide rod 62, polishing brush 63, push block 64, L-shaped rod 7, connecting rod 71.

[0030] In order to achieve the above object, the basic scheme of the present invention is as follows:

[0031] like figure 1 and figure 2 As shown, a metal processing method, the steps are as follows:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com