Odor-free DHA solid beverage capable of promoting mentality and invigorating brain and preparation method thereof

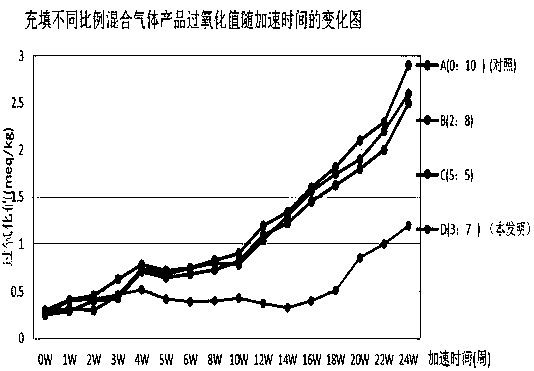

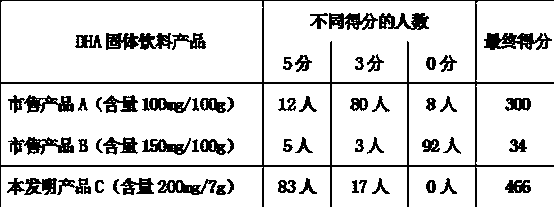

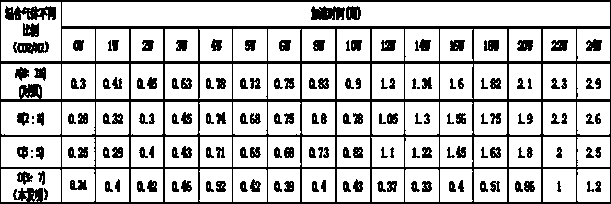

A technology of intelligence-enhancing brain and solid beverage, which is applied to the functions of food ingredients, food science, and applications. It can solve the problems of prone to oxidation, poor taste, and strong fishy smell of fish oil, so as to prevent oxidation. The effect of spoilage, improvement of cardiovascular and cerebrovascular diseases, and pleasant fruity flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] A kind of preparation method of DHA solid drink of brain-invigorating without fishy smell, comprises steps

[0034] 1) Put a batch of algae oil DHA powder into the boiling drying furnace at one time, use high-speed hot air to suspend the powder in a fluidized state, add water to β-cyclodextrin to make a liquid emulsion, and spray it through a high-pressure spray gun , spray into the β-cyclodextrin emulsion, so that the β-cyclodextrin is evenly sprayed on the DHA powder, and boiled and dried by hot air at 70-80 degrees for 30-40 minutes, so that the DHA powder is embedded in the β-cyclodextrin In the essence, the particle size is controlled at 60-80 mesh, and the moisture content is controlled within 5% after drying;

[0035] 2) Accurately weigh each material according to the recipe requirements, add DHA powder, sugar powder, mango powder, lemon powder after embedding β-cyclodextrin in step 1), choose to add walnut powder and phosphatidylserine (PS), Ascorbic acid, anhy...

Embodiment 1

[0041] 1) Put 10 kg of 10% algae oil DHA powder into the boiling drying furnace at one time, use high-speed hot air to suspend the powder in a fluidized state, and add 50 g of β-cyclodextrin to 950 ml of pure water to prepare The liquid emulsion is sprayed through a high-pressure spray gun to evenly spray β-cyclodextrin on the DHA powder, and boiled and dried by hot air (80 degrees) for 30 minutes. The particle size is controlled at 60-80 mesh, and the moisture after drying is controlled at 5. Within %.

[0042] 2) Accurately weigh each material according to the formula requirements, 2.05 kg of DHA powder embedded in β-cyclodextrin in 1), 0.80 kg of sugar powder, 1.0 kg of mango powder, 0.5 kg of lemon powder, 0.2 kg of ascorbic acid, no 0.85 kg of citric acid in water, 0.6 kg of sodium bicarbonate, 0.07 kg of carotene, 0.05 kg of sucralose, and 0.32 kg of orange oil powder. The above ingredients were mixed in a three-dimensional mixer for 12 minutes to make them evenly mixed...

Embodiment 2

[0046] 1) Put 10 kg of 10% algae oil DHA powder into the boiling drying furnace at one time, use high-speed hot air to suspend the powder in a fluidized state, and add 50 g of β-cyclodextrin to 950 ml of pure water to prepare The liquid emulsion is sprayed through a high-pressure spray gun to evenly spray β-cyclodextrin on the DHA powder, and boiled and dried by hot air (70 degrees) for 35 minutes. The particle size is controlled at 60-80 mesh, and the moisture after drying is controlled at 5 Within %.

[0047] 2) Accurately weigh each material according to the recipe requirements, 2.0 kg of DHA powder embedded in β-cyclodextrin in 1), 1.0 kg of sugar powder, 0.8 kg of mango powder, 0.5 kg of walnut powder, and 0.2 kg of phosphatidylserine , 0.3 kg of lemon powder, 0.3 kg of ascorbic acid, 0.1 kg of anhydrous citric acid, 0.3 kg of sodium bicarbonate, 0.05 kg of carotene, 0.03 kg of sucralose, and 0.22 kg of orange oil powder. The above ingredients were three-dimensionally mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com