Preparation method of CIGS compound, printing ink and film absorbing layer

A copper indium gallium selenide and compound technology, which is applied in the field of preparing thin film absorbing layers, can solve the problems of selenium component loss, component mismatch, difficult control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

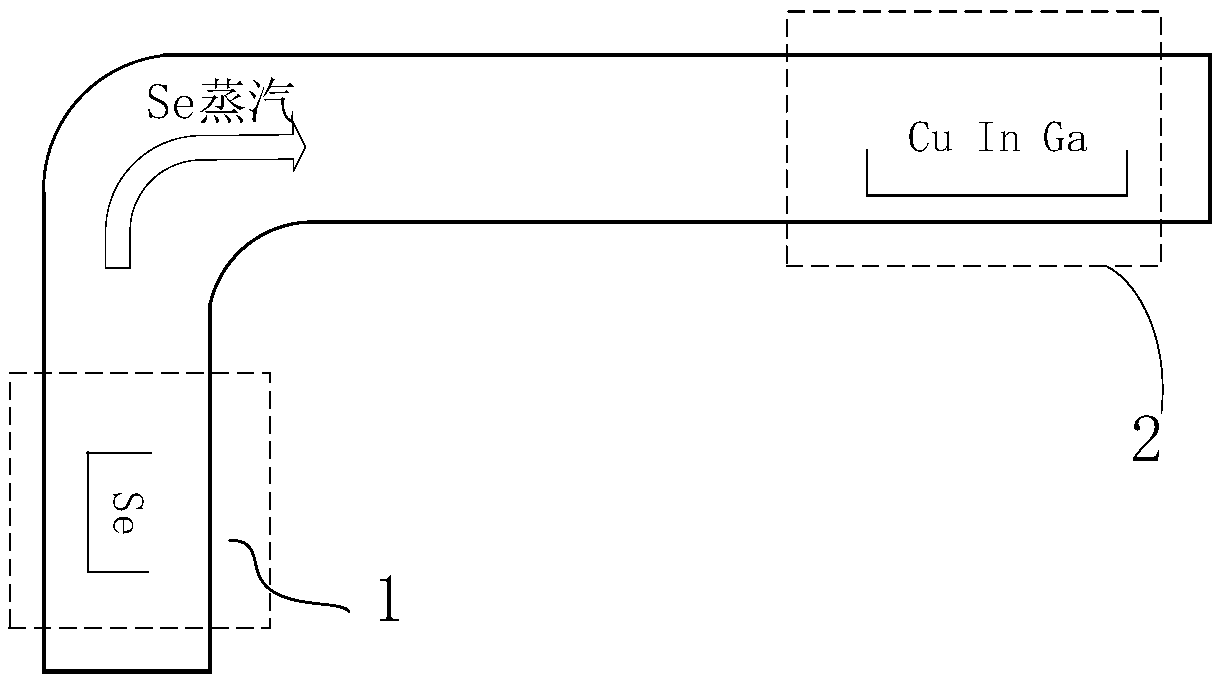

[0049] Such as figure 1 As shown, this embodiment provides a method for preparing copper indium gallium selenide compound, the steps are as follows:

[0050] S1 provides a vacuum container, and the vacuum container includes a high-temperature synthesis zone 1 and a low-temperature evaporation zone 2 arranged at intervals;

[0051] S2 places copper, indium, and gallium in the high-temperature synthesis zone 1, and places selenium in the low-temperature evaporation zone 2;

[0052] S3 heats the copper, indium, and gallium in the high-temperature synthesis zone 1 to a molten state, and heats the selenium in the low-temperature evaporation zone 2 to a gaseous state; the time when the selenium in the low-temperature evaporation zone 2 starts to change to a gaseous state is not earlier than the time when copper indium gallium is melted ;

[0053] S4 heats the high-temperature synthesis zone 1 and the low-temperature evaporation zone 2;

[0054]S5 lowering the temperature of the h...

Embodiment 2

[0065] The present embodiment provides a kind of method for preparing CIGS printing ink, comprises the following steps:

[0066] S1 Grinding the copper indium gallium selenide compound prepared in the above embodiment 1 into powder;

[0067] S2 adding solvent, binder and dispersant to the powder and stirring to form uniformly;

[0068] In S3, the mixture is evaporated by heating or standing to volatilize, and the solvent is removed to form a slurry.

[0069] In S1, the CIGS compound prepared in Example 1 can be ground into nanopowder by using a zirconia planetary ball mill. Of course, the method of pulverizing the CIGS compound is not limited to the zirconia planetary ball mill, and other methods can also be used, as long as the CIGS can be pulverized into Nano powder can be.

[0070] In S2, the copper indium gallium selenide compound powder is mixed with a solvent, a binder and a dispersant; the above mixture is stirred and ultrasonicated to form a uniform mixture. The sol...

Embodiment 3

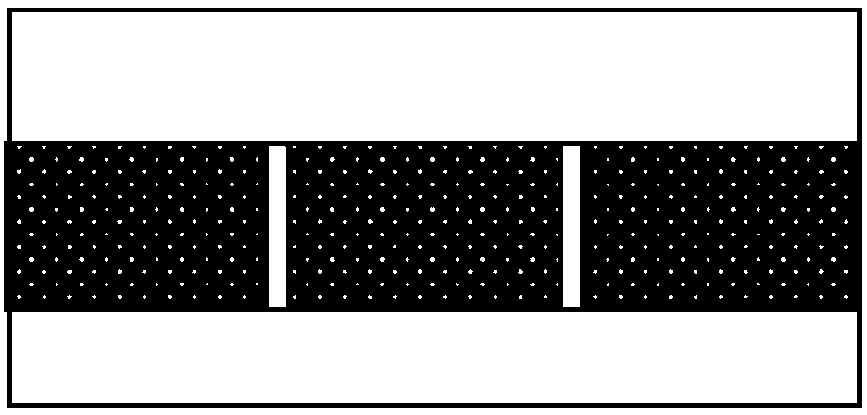

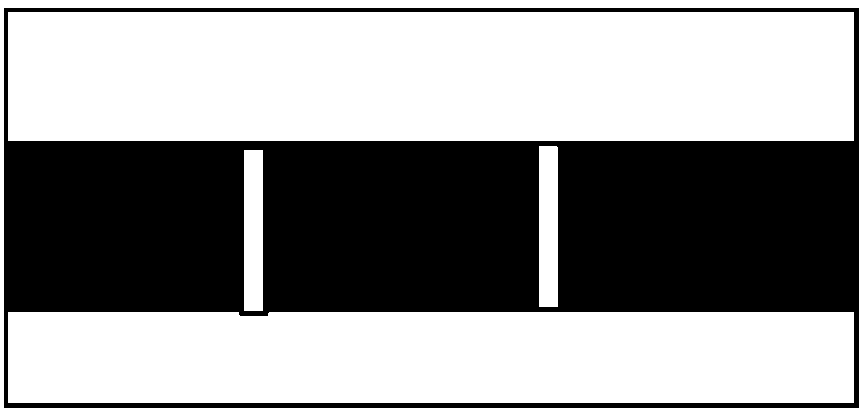

[0074] This embodiment provides a preparation method for preparing a copper indium gallium selenide light-absorbing layer. The copper indium gallium selenide ink prepared in embodiment 3 is used for coating the slurry on Mo-plated soda lime glass or stainless steel substrate by screen printing. Cloth, the coating method can be intermittent coating or continuous coating according to the overall process requirements of the thin film battery. Transfer the slurry-coated substrate into a continuous sintering furnace for slurry drying and annealing. The drying temperature is 150°C-250°C, the drying time is 3min-5min, the annealing temperature is 450°C-550°C, and the annealing time is 10min-15min , and finally get the absorbing layer with CIGS thin film.

[0075] In this embodiment, the ink prepared in embodiment 3 is on Mo-plated soda-lime glass or stainless steel substrate, and then the slurry is dried, and the liquid binding phase can be evaporated or decomposed during the drying ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com