Hydraulic loop of pump-controlled single rod piston cylinder

A hydraulic circuit, single-rod technology, used in fluid pressure actuating devices, servo motors, servo motor components, etc., can solve the problems of sudden changes in cylinder speed, high cost, and unsatisfactory energy-saving effects under alternating loads. Rapid speed change, low cost, good anti-alternating load characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

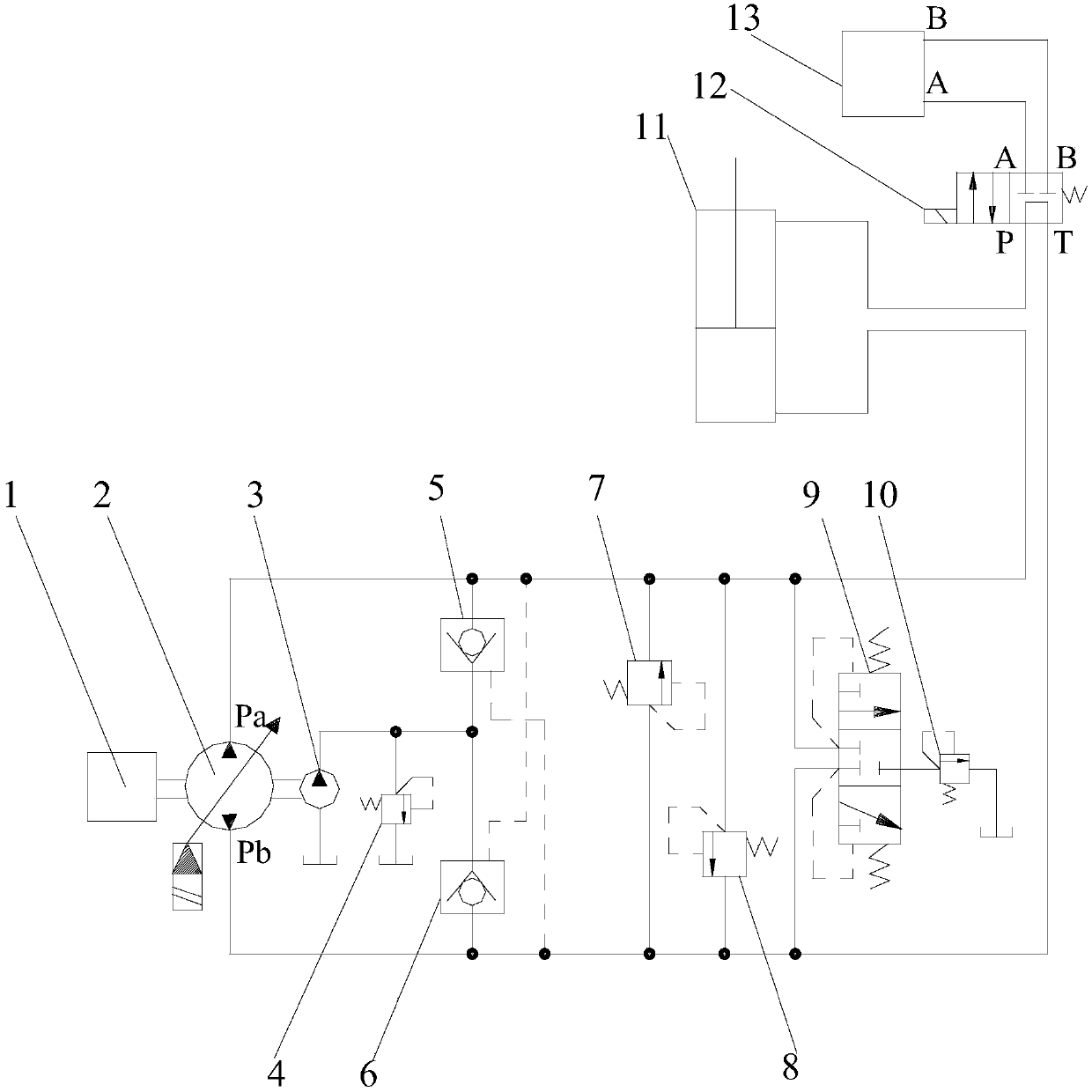

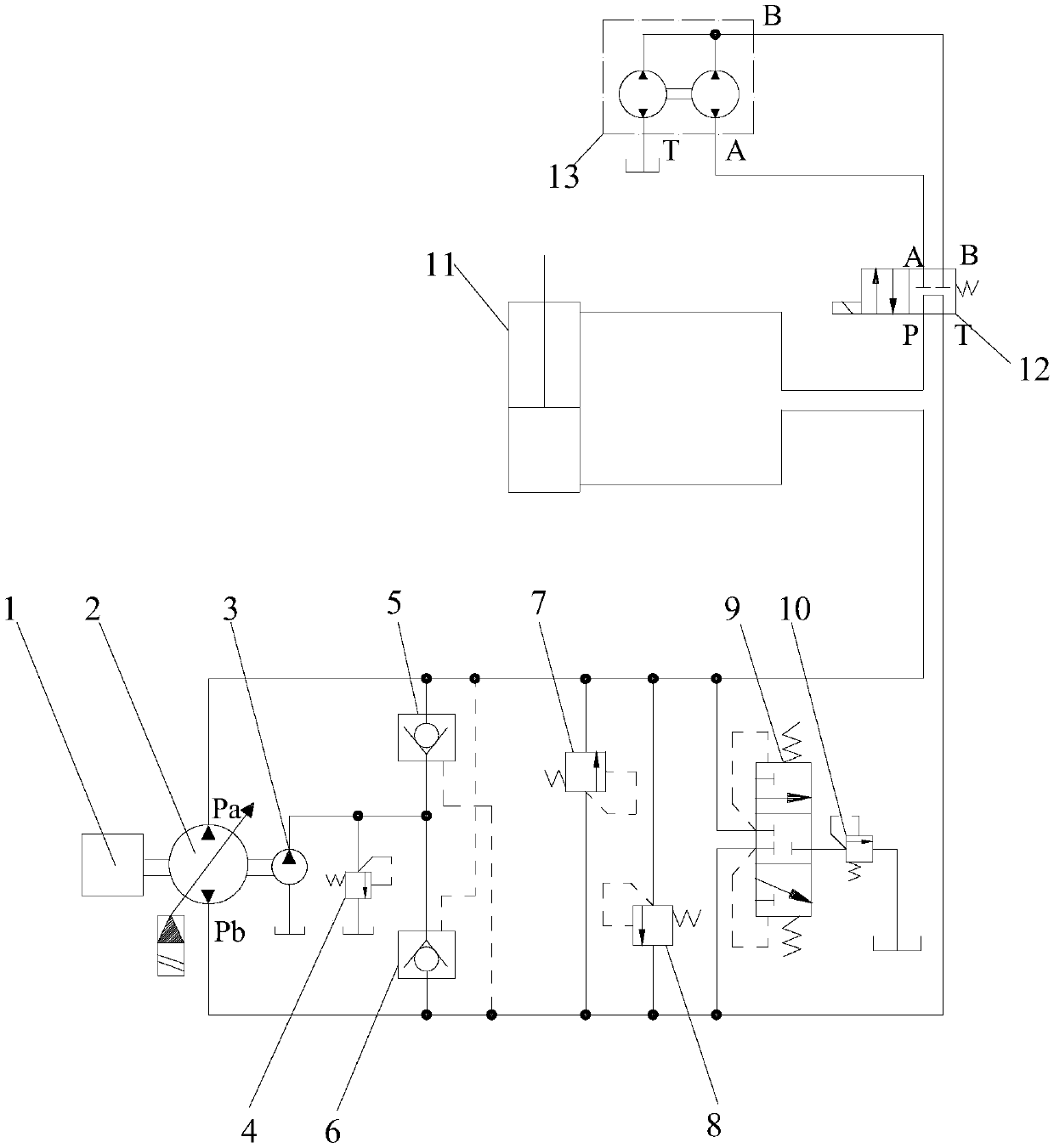

[0019] Such as figure 2 As shown, it includes prime mover 1, main pump 2, charge pump 3, first and second low-pressure relief valves 4 and 10, first and second hydraulic control check valves 5 and 6, first and second safety valves Valves 7, 8, shuttle valve 9, working cylinder 11, high pressure reversing valve 12, hydraulic transformer 13, oil tank, controller;

[0020] Prime mover 1, main pump 2, charge pump 3, first and second low pressure relief valves 4 and 10, first and second hydraulic control check valves 5 and 6, first and second safety valves 7 and 8, Shuttle valve 9, working cylinder 11, high-pressure reversing valve 12, hydraulic transformer 13, oil tank, and controller are connected in such a way that the main shafts of prime mover 1, main pump 2 and charge oil pump 3 are connected, and the Pa port of main pump 2 is connected to the The oil outlet of the first hydraulically controlled check valve 5, the hydraulically controlled port of the second hydraulically co...

Embodiment 2

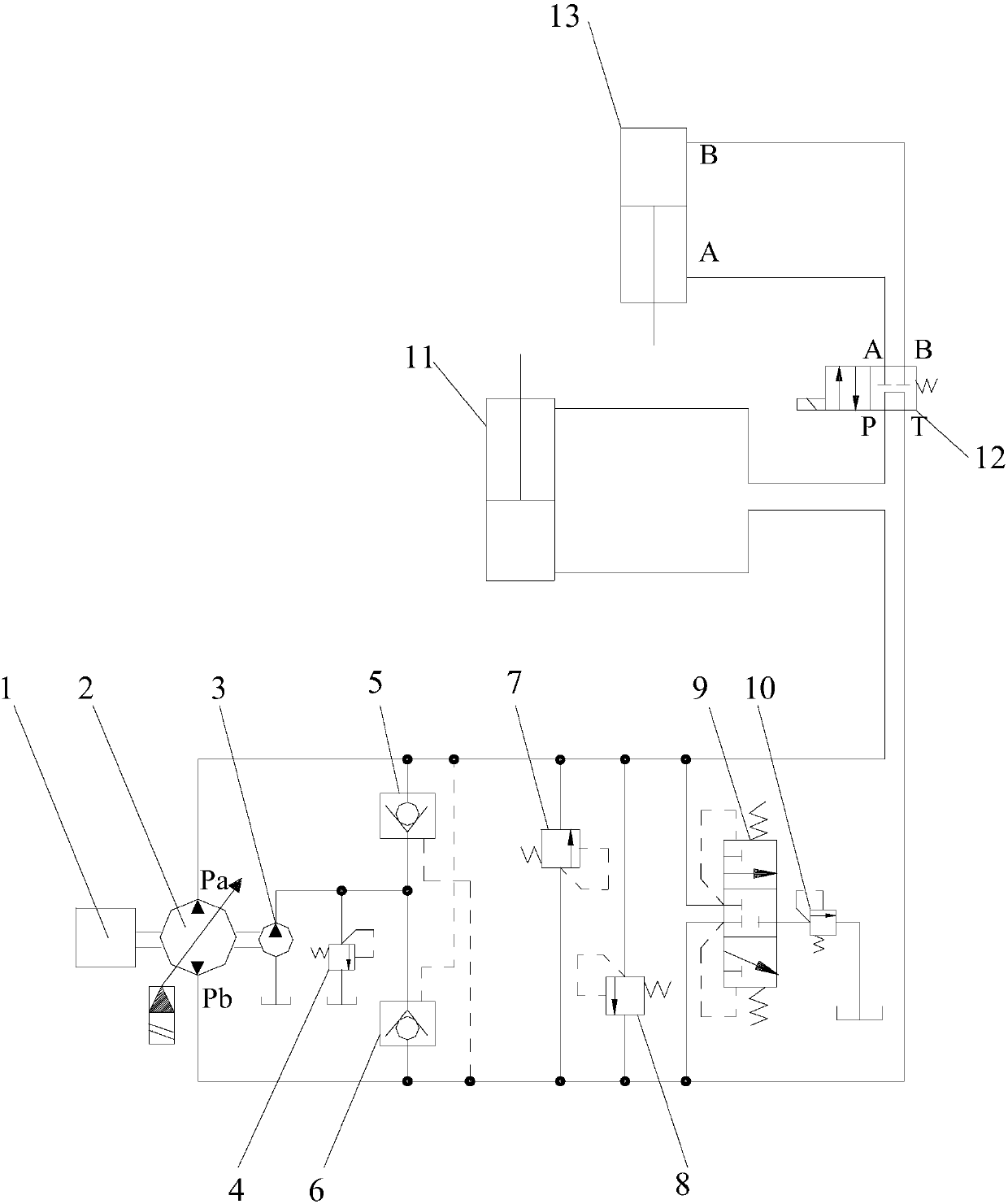

[0029] Such as image 3 As shown, it includes prime mover 1, main pump 2, charge pump 3, first and second low-pressure relief valves 4 and 10, first and second hydraulic control check valves 5 and 6, first and second safety valves Valves 7, 8, shuttle valve 9, working cylinder 11, high pressure reversing valve 12, hydraulic transformer 13, oil tank, controller;

[0030] Prime mover 1, main pump 2, charge pump 3, first and second low pressure relief valves 4 and 10, first and second hydraulic control check valves 5 and 6, first and second safety valves 7 and 8, Shuttle valve 9, working cylinder 11, high-pressure reversing valve 12, hydraulic transformer 13, oil tank, and controller are connected in such a way that the main shafts of prime mover 1, main pump 2 and charge oil pump 3 are connected, and the Pa port of main pump 2 is connected to the The oil outlet of the first hydraulically controlled check valve 5, the hydraulically controlled port of the second hydraulically con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com