Efficient polyester composite catalyst and preparation method and application thereof

A composite catalyst and polyester technology, applied in the field of polyester catalysts, can solve the problems of easy hydrolysis, low selectivity, and poor product hue.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

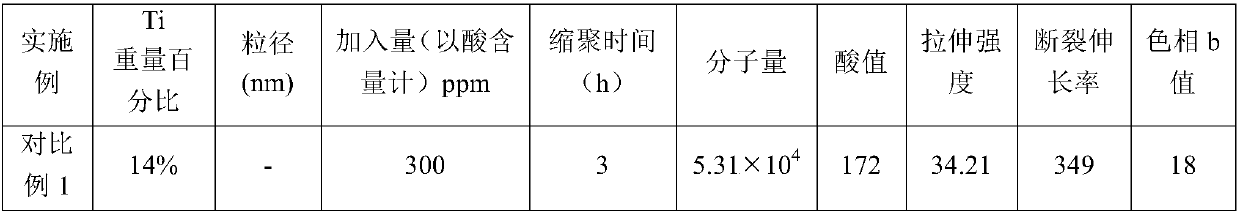

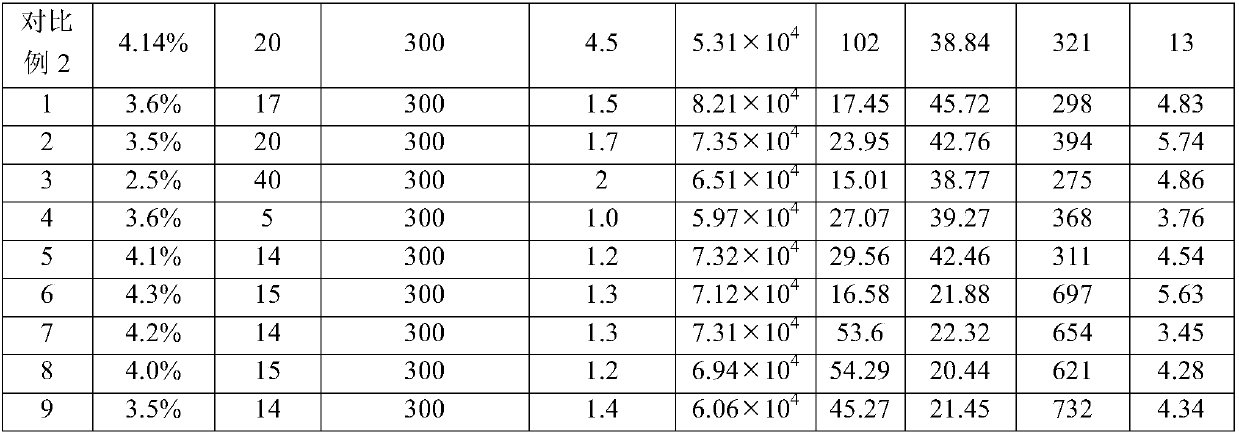

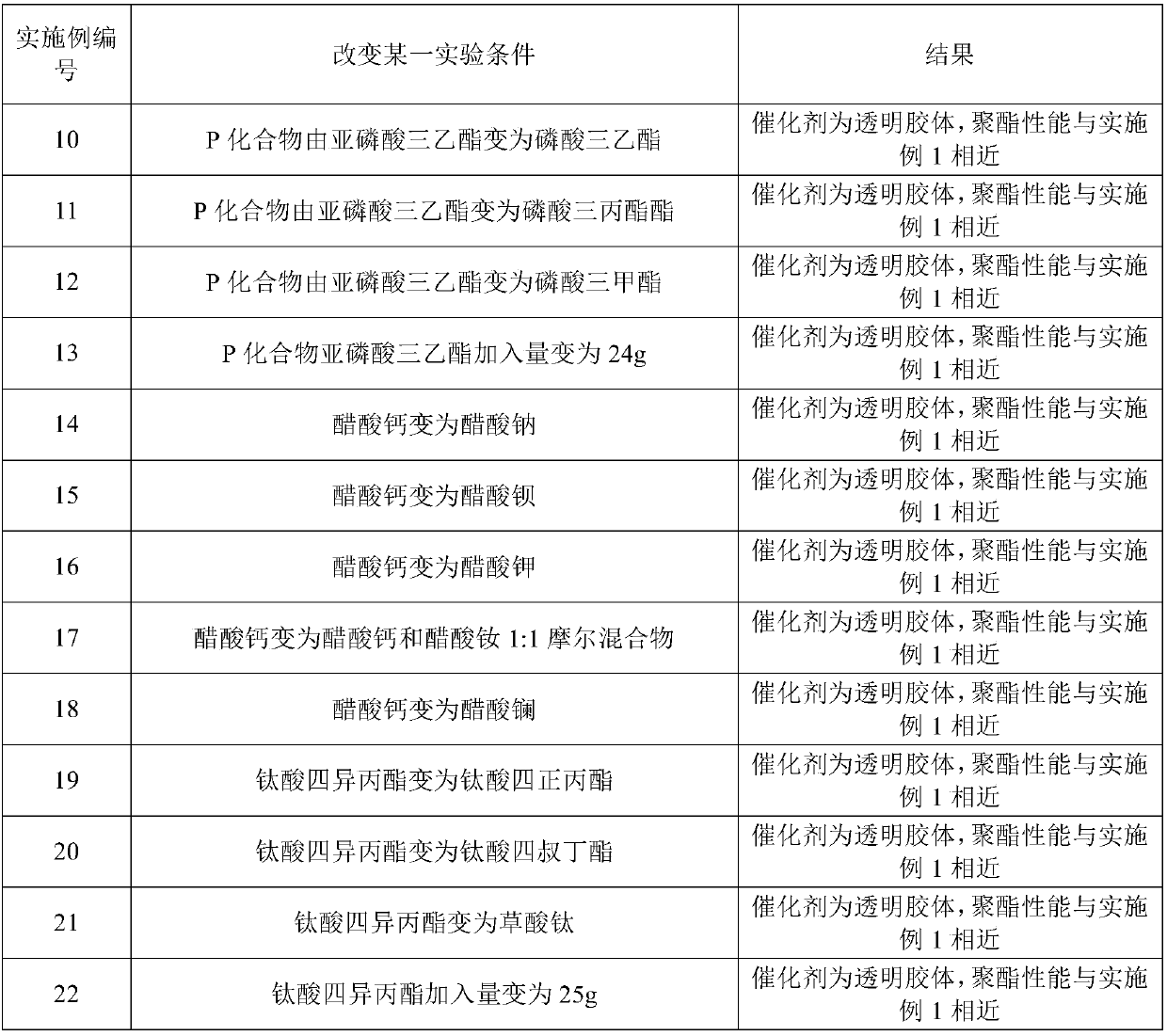

Examples

Embodiment 1

[0083] A kind of efficient polyester composite catalyst, its preparation comprises the steps:

[0084] Add 160g of absolute ethanol to 75g of tetraisopropyl titanate and 12g of ethyl orthosilicate and stir at room temperature for 1 hour to obtain product X. Dissolve 32g of citric acid in 200ml of ethanol to obtain a mixture Y, and then slowly drop the mixture Y into In the product X, react at room temperature for 2h. Raise the temperature to 100°C, add 12g triethyl phosphite and 8g calcium acetate trihydrate in turn, react for 2 hours and then raise the temperature to 150°C to distill out small molecules, and then add 10ml butanediol to dilute after the distillation speed slows down significantly ; Cooling discharge obtains polyester composite catalyst, weighs, calculates Ti content, and dynamic light scattering measures particle size, and the results are shown in Table 1.

[0085] The application of described high-efficiency polyester composite catalyst in catalytic polyeste...

Embodiment 2

[0088] A kind of efficient polyester composite catalyst, its preparation comprises the steps:

[0089] Add 160g of absolute ethanol to 75g of tetraisopropyl titanate and 30g of tetraisopropyl titanate and 30g of ethyl orthosilicate and stir for 0.2h at 40°C to obtain product X; at the same time, dissolve 65g of citric acid in 50ml of ethanol to obtain a mixed solution Y, and then mix the mixed solution Y Slowly drop into the product X, react at room temperature for 2h. Raise the temperature to 120°C, add 48g of triethyl phosphate, react for half an hour, then add 16g of sodium acetate trihydrate, react for 2 hours, then raise the temperature to 150°C to distill out small molecules, and add 10ml after the distillation speed slows down significantly Diluted with 1,3-propanediol; cooled and discharged to obtain a high-efficiency polyester composite catalyst, weighed, calculated the Ti content, and measured the particle size by dynamic light scattering. The results are shown in Ta...

Embodiment 3

[0093] A kind of efficient polyester composite catalyst, its preparation comprises the steps:

[0094] Add 362.58g of butanediol to 75.26g of tetrabutyl titanate and 285.8g of ethyl orthosilicate and stir at 78°C for 0.1h to obtain product X. Dissolve 130g of citric acid in 300ml of ethanol to obtain a mixture Y, and then mix the mixture Y Slowly drop into the product X, react at room temperature for 6h. Raise the temperature to 100°C, add 200.5g of phosphinate and 8.69g of cobalt acetate in turn, react for 4 hours and then raise the temperature to 150°C to distill out small molecules, and then add 10ml of butanediol to dilute after the distillation speed slows down significantly; Cool and discharge to obtain a high-efficiency polyester composite catalyst, weigh it, calculate the Ti content, and measure the particle size by dynamic light scattering. The results are shown in Table 1.

[0095] The application of described high-efficiency polyester composite catalyst in catalyti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com