Aluminium titanate-spinel saggar, preparation method and application thereof

A spinel and aluminum titanate technology, applied in the field of refractory kiln furniture, can solve the problems of low service life of the saggar, affecting the service life of the saggar, spalling, cracking, etc., and achieves good dimensional stability, high cost performance, and is not easy to cracked effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

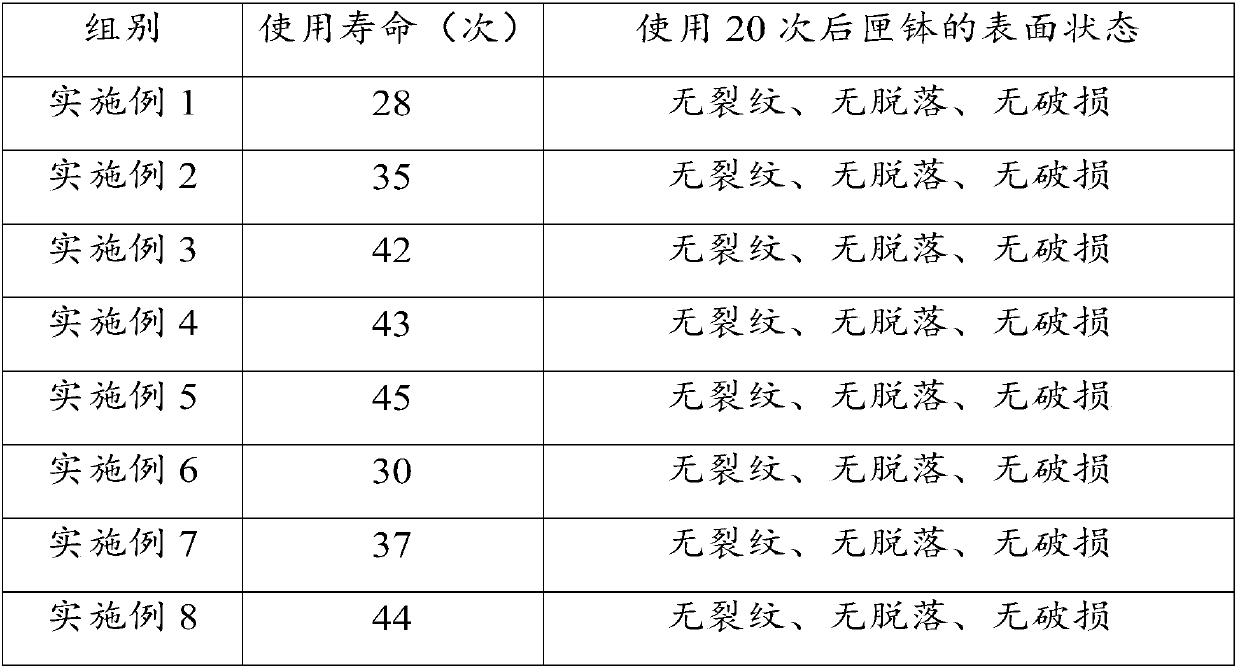

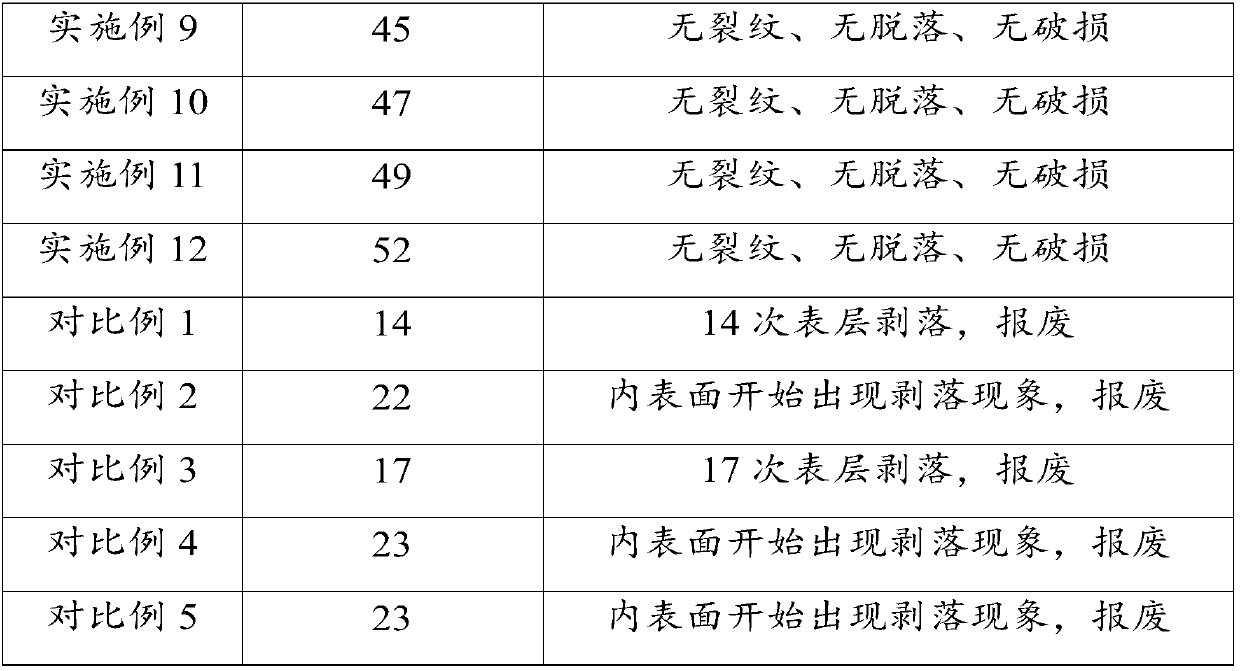

Examples

preparation example Construction

[0040] In a second aspect, the present invention provides a method for preparing the above-mentioned aluminum titanate-spinel sagger, comprising the following steps: uniformly mixing the raw materials in the formula amount, then adding a binder and mixing uniformly again to obtain a mixture, the mixture The aluminum titanate-spinel sagger can be obtained after molding and firing. The process steps of the above preparation method are simple, only need to mix the raw materials evenly, add the binder and mix evenly again, and then it can be obtained after molding and firing, the processing is simple, and the prepared aluminum titanate-spinel sagger has low cost Low cost, high cost performance, strong corrosion resistance, good thermal stability and long service life.

[0041] In a preferred embodiment, the binder includes pulp waste liquid, and the addition amount of pulp waste liquid is 3%-4%. Pulp waste liquid is the waste discharged from paper mills. It contains lignin and it...

Embodiment 1

[0049] An aluminum titanate-spinel sagger, which is mainly prepared from the following raw materials in parts by mass: 25 parts of aluminum titanate with a particle size not greater than 2mm, 15 parts of spinel with a particle size not greater than 1mm, and 20 parts of spinel larger than 46.9 μm, 8 parts of titanium dioxide, 12 parts of alumina, 0.5 parts of magnesium oxide powder, and 2 parts of yellow dextrin.

Embodiment 2

[0051] An aluminum titanate-spinel sagger, which is mainly prepared from the following raw materials in parts by mass: 35 parts of aluminum titanate with a particle size not greater than 2mm, 25 parts of spinel with a particle size not greater than 1mm, and 30 parts of spinel larger than 46.9 μm, 12 parts of titanium dioxide, 16 parts of aluminum oxide, 1.5 parts of magnesium oxide powder, and 4 parts of yellow dextrin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com