Method for preparing nano NTC (Negative Temperature Coefficient) thermal-sensitive material

A heat-sensitive material and nanotechnology, applied in the field of preparation of nano-NTC heat-sensitive materials, can solve the problems of complex preparation methods, inability to obtain dense nano-NTC heat-sensitive materials, expensive equipment, etc., to avoid particle growth and crystallization effect of grain coarsening, high material constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] S1 nano powder preparation: 46.48ml concentration is 50% Mn (NO 3 ) 3 solution and 20.36g of Ni(NO 3 ) 2 ·6H 2 After O mixing, add deionized water until completely dissolved, then add 67.50g of citric acid, stir until completely dissolved, then add 18.59ml of ethylene glycol, mix well to obtain a transparent solution; then adjust the pH value of the transparent solution to 3 with ammonia water, Then put the transparent solution in a 70°C water bath to stir and evaporate the solvent to obtain a wet gel, then transfer the wet gel to an oven at 120°C until it is completely dried to obtain a dry gel, then place the dry gel on In the muffle furnace, the temperature was raised to 500°C at a rate of 2°C / min and kept for 1 hour to obtain a calcined powder. Add 95% ethanol to the calcined powder and put it in a ball mill for 1 hour, then put it in an oven at 100°C until completely drying to obtain nickel-manganese spinel powder.

[0025] S2 Tabletting: The obtained nickel-m...

Embodiment 2

[0029] S1 nano powder preparation: 46.48ml concentration is 50% Mn (NO 3 ) 3 solution and 20.36g of Ni(NO 3 ) 2 ·6H 2 After O mixing, add deionized water until completely dissolved, then add 67.50g of citric acid, stir until completely dissolved, then add 18.59ml of ethylene glycol, mix well to obtain a transparent solution; then adjust the pH value of the transparent solution to 3 with ammonia water, Then put the transparent solution in a 70°C water bath to stir and evaporate the solvent to obtain a wet gel, then transfer the wet gel to an oven at 120°C until it is completely dried to obtain a dry gel, then place the dry gel on In the muffle furnace, the temperature was raised to 500°C at a rate of 2°C / min and kept for 1 hour to obtain a calcined powder. Add 95% ethanol to the calcined powder and put it in a ball mill for 1 hour, then put it in an oven at 100°C until completely drying to obtain nickel-manganese spinel powder.

[0030] S2 Tabletting: The obtained nickel-m...

Embodiment 3

[0033] S1 nano powder preparation: 46.48ml concentration is 50% Mn (NO 3 ) 3 solution and 20.36g of Ni(NO 3 ) 2 ·6H 2 After O mixing, add deionized water until completely dissolved, then add 67.50g of citric acid, stir until completely dissolved, then add 18.59ml of ethylene glycol, mix well to obtain a transparent solution; then adjust the pH value of the transparent solution to 3 with ammonia water, Then put the transparent solution in a 70°C water bath to stir and evaporate the solvent to obtain a wet gel, then transfer the wet gel to an oven at 120°C until it is completely dried to obtain a dry gel, then place the dry gel on In the muffle furnace, the temperature was raised to 500°C at a rate of 2°C / min and kept for 1h to obtain calcined powder. Add 95% ethanol to the calcined powder and put it in a ball mill for 1h, then put it in an oven at 100°C until completely drying to obtain nickel-manganese spinel powder.

[0034]S2 Tabletting: The obtained nickel-manganese sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

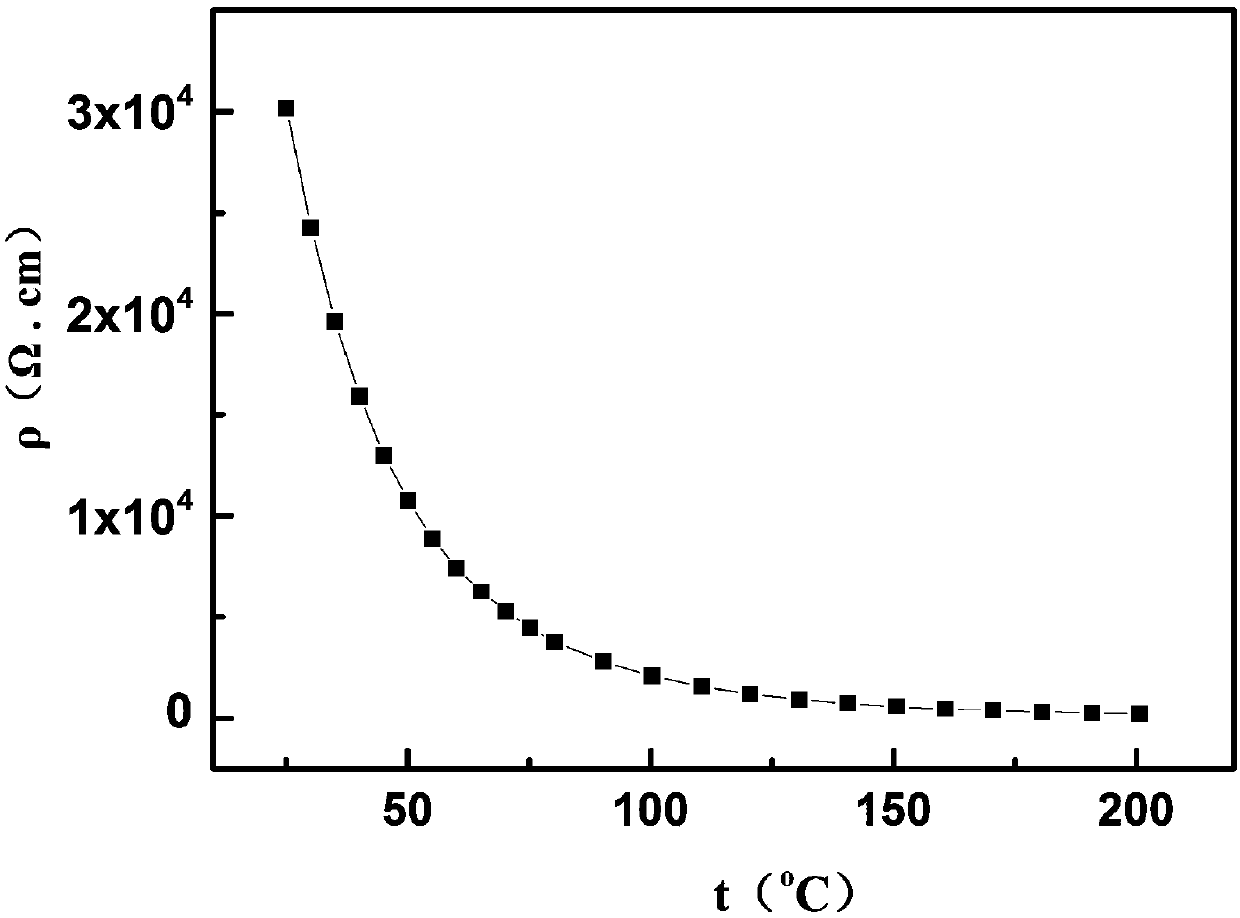

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com