Egg-yolk puff and making process thereof

A production process, a technology for egg yolk crisp, which is applied in the field of cake processing and can solve problems such as soft taste and easy sticking to teeth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] Example 1: Egg yolk crisps, the components included and their corresponding qualities are shown in Table 1, and are prepared through the following steps:

[0072] A. Production of the water-oil skin layer: fully mix high-gluten flour, low-gluten flour, and white sugar powder to form the first mixture; add water to the obtained first mixture, mix well, and knead to form the water-oil skin layer;

[0073] B, making the crisp layer: fully mix the flour and shortening, knead to form the crisp layer;

[0074] C, the production of dough: wrap the water-oil skin layer obtained in step A on the outside of the crispy layer obtained in step B, flatten to 3mm, fold into three, repeat the operation twice, and then flatten to 3mm to form a dough ;

[0075] D, the production of the core layer: select the salted duck egg yolk, and evenly spray the wine (white wine, alcohol content: 38°) on the surface of the salted duck egg yolk, bake at 153°C for 12min, cool to 50°C, turn over , an...

Embodiment 2-6

[0080] Examples 2-6: egg yolk crisps, the difference from Example 1 lies in that the included components and their corresponding qualities are shown in Table 1.

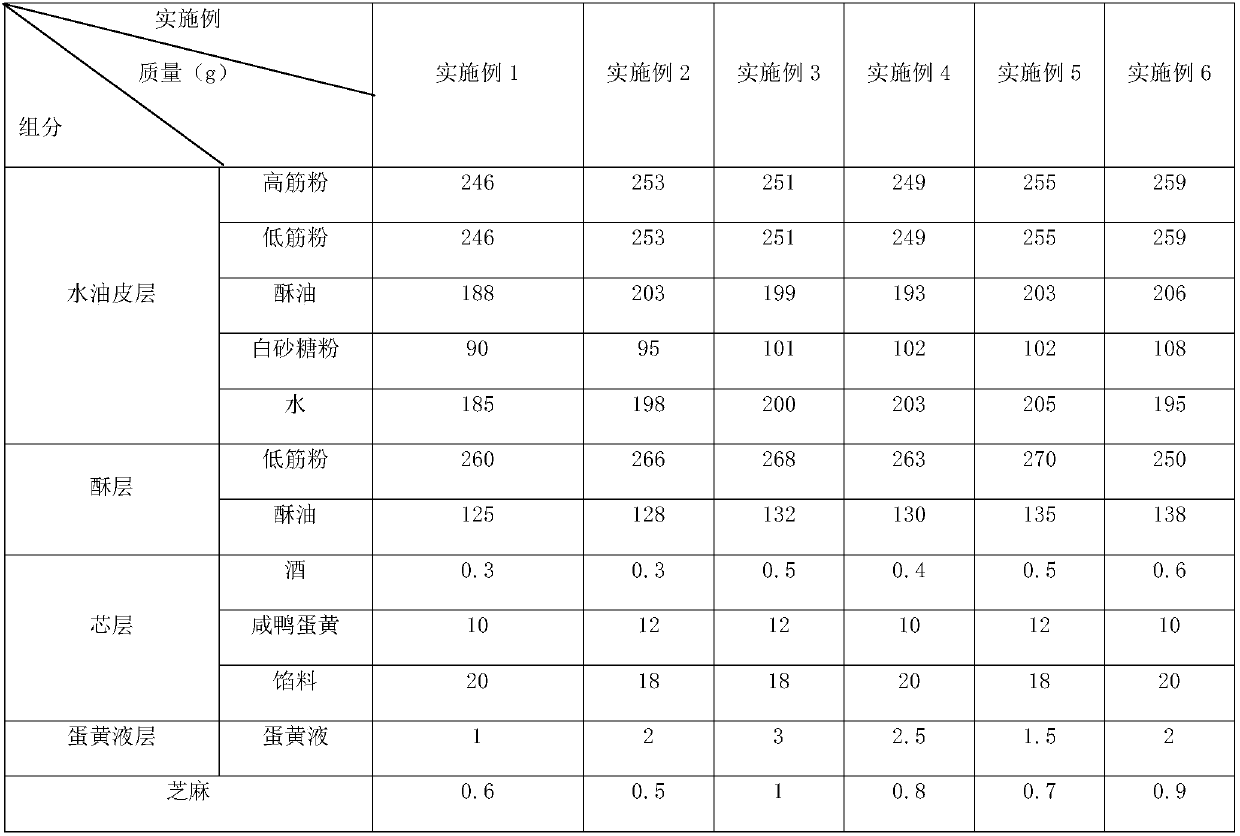

[0081] Components included in table 1 embodiment 1-6 and their corresponding quality (water oil cortex, crisp layer in 1kg)

[0082]

Embodiment 7

[0083] Embodiment 7: Egg yolk crisp, the difference from Embodiment 1 is that in step C, it is flattened to 2mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com