Rubber-like material for the immobilization of proteins and its use in lighting diagnosis and biocatalysis

A rubber-like, protein-based technology used in biochemical equipment and methods, microbial assay/inspection, luminescent materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0341] Example 1 : Preparation of Rubber-like Materials Containing Immobilized Proteins

[0342] Preparation of proteins and enzymes (expression and purification of recombinant proteins)

[0343] Such as figure 1As shown, several different photoproteins and enzymes were prepared and characterized. Escherichia coli (E.coli) strain M15[pREP4] carrying the appropriate plasmid (both pQE-9 expression constructs containing the N-terminal 6xHis tag from the pQE-9 expression vector, Qiagen) was incubated at 28°C in the presence of Amp (200 μg / ml) and Kan (100 μg / ml) antibiotics grown in LB medium to an optical density at 600 nm of about 0.5. Recombinant protein expression was induced using 1 mM isopropyl-β-D-1-thiogalactoside at 28°C. After 4 hours of growth at 28°C, cells were harvested and frozen at -20°C. Frozen bacterial cells were thawed and lysed chemically using lysozyme and mechanically using a sonicator. Then, following the QIAGEN protocol (Henco K, A handbook for hi...

Embodiment 2

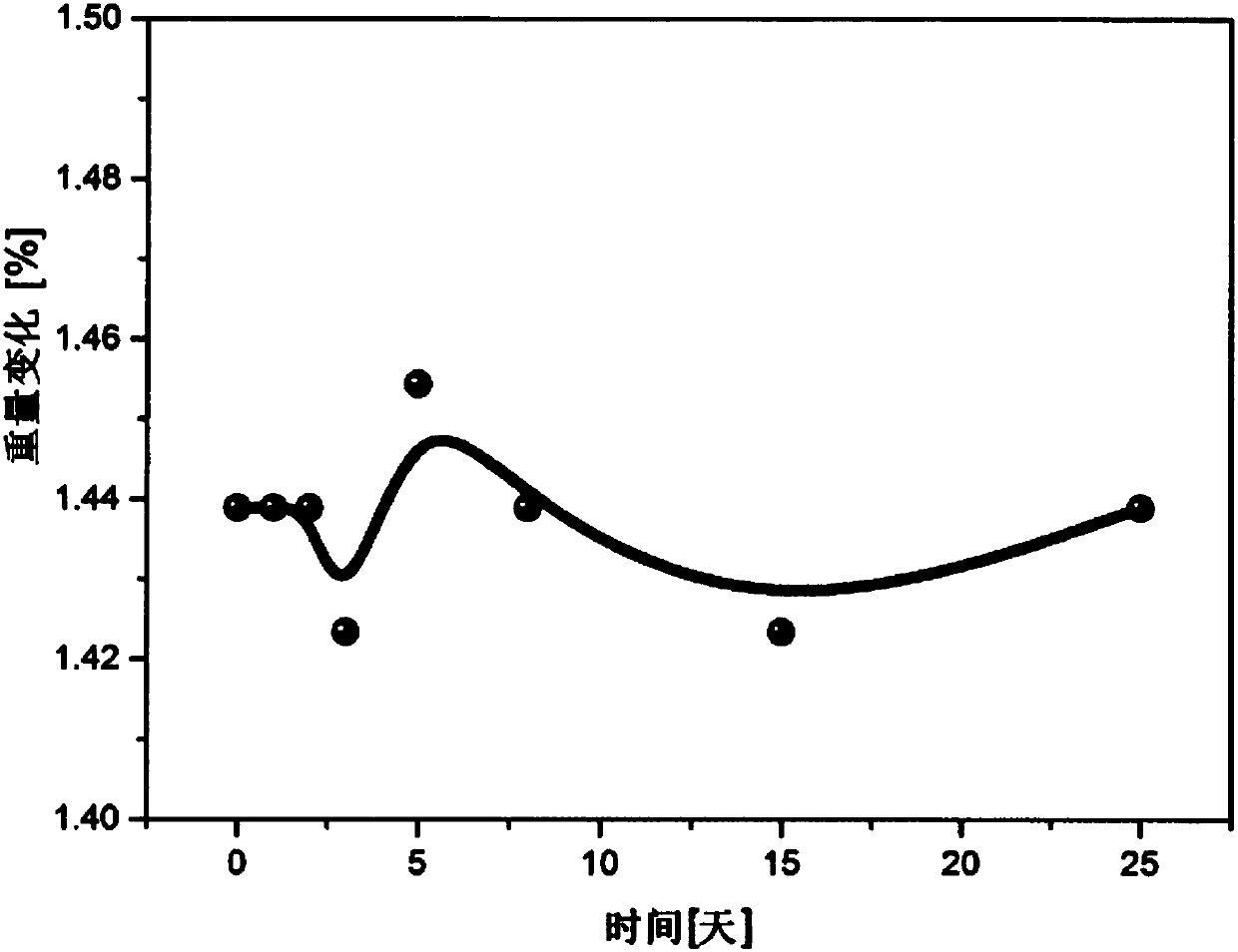

[0357] Example 2 : Preparation of rubber-like materials using different mass ratios of branched polymers and linear polymers and different amounts of buffered aqueous solutions

[0358] The preparation of gels and rubber-like materials according to the present invention uses different mass ratios of branched polymers (in this example, M n 450 Da ethoxylated trimethylolpropane (TMPE)) and linear polymers (in this example, M n 5000 kDa polyethylene oxide (PEO)), as shown in Table 1 and Table 2 below. Rubber formation was performed as described in Example 1.

[0359] Specifically, the above two polymers were mixed in different mass ratios as shown in Table 1 and Table 2 below. Although TMPE is a low-viscosity liquid, PEO does not dissolve even under high-speed stirring conditions. To facilitate this process, different amounts of buffer (again for proteins) were added.

[0360] Table 1:

[0361]

[0362] Table 2:

[0363]

[0364]As summarized in Table 1, until 200 µ...

Embodiment 3

[0369] Example 3: Applications of rubber-like materials containing immobilized proteins as downconversion encapsulation systems

[0370] Figure 5 A schematic diagram showing a hybrid light-emitting diode with a rubber-like material containing immobilized proteins therein as a down-converting packaging system (see Example 1). A commercially available blue emitting LED with an electroluminescence spectrum at 450 nm (from Luxeon) was used in this example. To coat the previous silicone encapsulation in three-dimensional form, the LED can either be immersed in the gel for a few seconds and / or the gel can be deposited by drop coating onto the surface of the carrier. Subsequently, the coating was dried as described in Example 1 above. Devices were driven under constant and / or pulsed current and voltage regimes. In this example, a Keithley 2400 was used to drive the LED at a constant current of 10 mA, and the electroluminescence spectrum and device performance was monitored usin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| number average molecular weight | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com